- Outdoor Living and Backyard Ideas Home

- Top trends in outdoor concrete design

- Outdoor room checklist (PDF)

- Fire Pit or Fireplace?

- Ways to Enhance Outdoor Rooms

- Outdoor fireplaces

- Fire pits

- Outdoor kitchens and countertops

- Seat walls

- Outdoor Concrete Furniture

- Concrete planters

- Backyard Landscaping with Concrete

- Concrete patios

- Landscape borders

- Stairs and steps

- Concrete walkways

- Concrete garden bridges

- Water features

- Architectural accents

- Concrete statuary

- Backyard Landscaping: Get more ideas from LandscapingNetwork.com

- Backyard Recreation Options

- Concrete pool decks: Design and layout tips

- Concrete tennis courts: Planning and construction

- Other Resources

- Outdoor Decorative Floors

- Free Outdoor Living Catalog

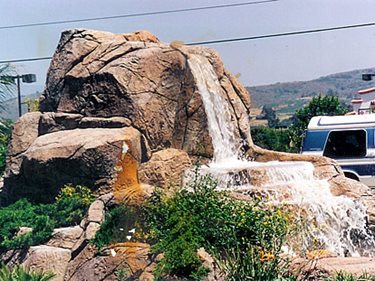

Concrete Water Features

How to use "faux rock" made of concrete to create stunning backyard waterscapesArtificial rocks made of concrete or other materials are a dramatic yet economical way to enhance water features, landscapes, buildings, and more. View our gallery of concrete water feature pictures.

Rock and stone have long been valued as natural, distinctive landscaping elements. But imagine the equipment, effort, and expense that would be required to haul large boulders weighing at least a ton each into a backyard and then to stack them around an in-ground pool or pond water feature.

That's why more and more landscape and swimming pool designers and contractors are turning to faux rock for water feature construction. Not only can artificial rocks be molded, textured, and colored to exactly replicate the look and feel of real rock formations, they also can be built onsite, eliminating the inconvenience and expense of hauling in material to build a water feature.

Benefits and Applications of Faux Rock

What is Faux Rock?

Rock and stone have long been valued as natural, distinctive landscaping elements. But getting the rock exactly where you want it, even if you live in an area where real rock is readily available, is no easy feat. Imagine, for example, the equipment, effort, and expense that would be required to haul large boulders weighing at least a ton each into a backyard and then to stack them around an in-ground pool or pond.

That's why more and more landscape and swimming pool designers and contractors are turning to faux rock. Not only can artificial rocks be molded, textured, and colored to exactly replicate the look and feel of real rock formations, they also can be built onsite, eliminating the inconvenience and expense of hauling.

Other benefits of faux rock include:

- Design flexibility

- Ease and speed of installation

- Durability

- The ability to conceal unsightly plumbing and other utilities

Faux rock can be made from a variety of materials including fiberglass, synthetic materials, rubber, and plaster. However, polymer-modified or glass-fiber-reinforced concrete are the most common materials used because the concrete can easily be sculpted or molded to achieve very realistic results. Concrete mixtures can produce rocks that are extremely strong (up to 9600 psi) and lightweight (when made with lightweight aggregates). In some cases, artificial rocks can be more durable than the natural stones they imitate.

Applications for Faux Rock

In addition to being popular enhancements for waterscapesparticularly pools, waterfalls, and spasartificial rocks have many other applications, both residential and commercial:

Design Ideas for Concrete Water Features

Water Feature Design: What goes into the design, engineering and construction of concrete water features

Incorporating Concrete Garden Bridges

Concrete Water Feature Projects: See these amazing waterscape creations

- Retaining walls and fences

- Erosion control

- Animal habitats

- Golf courses and parks

- Terraces and pool decks

- Wall veneers

- Cliff faces

- Planter boxes

- Seating and conversation pits

- Fish ponds

Here is a photo tour showing dramatic examples of some of these faux-rock applications. [Click Here]

How Faux Rock Is Made and Installed

Common Methods of Faux Rock Construction

There's more than one way to build a faux rock. When concrete is the material of choice, a variety of construction techniques can be used, but most fall into two main categories: cast or sculpted.

Casting techniques produce the most realistic-looking artificial rock because the molds against which the concrete is cast are copies of real rock surfaces. Manufacturers make the molds by applying silicone or latex rubber to the natural rocks they want to mimic. After the material hardens, the skin is peeled off and used to apply realistic stone textures to artificial rock surfaces.

For sculpted rock, contractors apply layers of shotcrete to a framework of reinforcing bars and metal lath. Then they use hand tools to sculpt the concrete into the desired shape and texture. Because the concrete is reinforced, this is an ideal technique for tall or cantilevered rock formations. Depending on the situation, contractors may use a straight mortar mix or a fiber-reinforced synthetic concrete (FRSC) mix. When the latter is used, rebar and lath may no longer be necessary for support. Even when applied at a thickness of only 2 to 3 inches, FRSC is extremely strong.

Texturing and Staining Techniques

Texturing and coloring are the keys to producing natural-looking artificial rock. Many methods of texturing can be completed in less than an hour, even with larger rock features. One common method of texturing rocks is to use a brush to dash a thin concrete mixture onto the rocks. Another is to use a rubber skin or even tin foil to imprint the desired texture onto the rocks.

Once the right texture has been achieved, contractors replicate the earth tones of weathered stone by using a variety of coloring techniques. Some contractors integrally color the concrete, while others prefer to use acid stains. Occasionally contractors combine both techniques to achieve the desired look. Faux rocks can even be stained with standard concrete stains or paints available at home-improvement stores. Depending on the desired look, stains and paints can be applied by a variety of techniques including spray equipment, brushes, sponges, or splattering.

To protect the finished work from degradation and discoloration caused by weathering and exposure to water. Some contractors recommend applying two to four coats of sealer as a final step. To speed application, a pump-type sprayer can be used.When treated with a good sealer, faux rock can last a lifetime, according to some contractors.

Installation Options

Smaller faux-rock features, such as ponds, can be completed in as little as 4 days. For these projects, the rock often is built off-site and transported to its final destination. For example, some companies offer a collection of artificial boulders made of glass-fiber-reinforced concrete or fiberglass that landscapers can artfully arrange around ponds and gardens. The sizes range from small (17 inches long by 9 inches tall) to massive (8 feet long by 5 feet tall). But even the largest GFRC boulder weighs less than 400 pounds.

Larger rock formations, such as those required for waterfalls or spas, typically are constructed onsite. The average time required to build a faux rock water feature ranges from 3 - 20 days depending on the size. This includes the time required for the concrete to cure and the stain and sealer coats to dry. One of the benefits of onsite construction is the ability to conceal elements in the work. Landscapers can design the rock formations around plumbing fixtures, lights, speakers, and other utilities and equipment.

Related Information

Using Concrete in Landscape Design

Water Features on LandscapingNetwork.com: How to capture the effects of water with waterfalls or vanishing edge design

Concrete Contractors: Find Vertical & Rock Mixes