Because concrete countertops are made from scratch, you can choose from a wide range of finishes, from mirror smooth to stone-like textures. In some cases, the surface of the form itself imparts the finish, with its texture reproduced in the concrete. Another option is to trowel the concrete surface, which allows you to create unique hand-crafted textural effects. If you want to achieve an ultra-smooth, seamless surface, then polishing or sanding the concrete after it’s cast is the best approach. Polishing can also be used to expose decorative aggregate, glass, or stone within the concrete, resulting in terrazzo-like finishes. Here are examples and design ideas for all of the different finishing techniques.

Marbleized or Veined Finish

There are several ways to make concrete countertops look like high-end granite or marble. Some specialized prepackaged concrete mixes allow you to achieve distinctive veining effects when the concrete is cast. Similar effects can be achieved by hand packing the concrete into the form, using contrasting colors to create the veining. Veined finishes can also be produced by casting voids into the concrete and then filling them in later with colored grout.Custom Concrete Countertops Resemble Appalachian Stone

Endless Concrete Design, Zionsville, Pa.

GFRC Admixture System Creates Beautiful Marbelized Countertops

Concrete Countertop Solutions

Special-Effects Countertops

Blue Concrete, Covington, GA

Design ideas:

- To create the realism of natural stone, cast the concrete in an integral color and then apply acid stain in layers to the top surface.

- Vary the pigments and degree of marbelizing to achieve one-of-a-kind custom pieces.

- If the countertop has seams, you can make them less noticeable by hiding them in the veining.

Wood-Grained Finish

Wood-grained finishes can easily be achieved in concrete by using a technique called “board forming,” which involves casting the concrete in forms lined with real wood planking or wood-grained form liners. The roughness of the unfinished wood imparts a distinct wood-grain texture in the concrete surface.Concrete Goes Back to the Ranch

Stamped Artistry, Pasadena, Texas

Concrete Table Mimics Reclaimed Wood

JM Lifestyles LLC, Randolph, N.J.

Design ideas:

- For the greatest realism, give the edges of the countertop a wood-grained texture as well by using strips of wood lath or bark-textured form liners along the edges during casting.

- To create distinct board lines, you can sawcut straight lines into the concrete surface after it’s cast.

- Use a combination of integral color and topical stains to replicate the realistic color variations of weathered wood.

Hand-Troweled Finish

Hand troweling the countertop surface rather than casting it against a form allows you to create a variety of textural effects, ranging from smooth to roughened. These finishes often look like natural stone because they are more variegated and have greater textural depth.Pseudo-Slate Countertop

Cliffe Concrete, Lucknow, Ontario

Old-World Countertops

Trueform Concrete, Flanders, N.J.

Concrete Island Warms Up Kitchen

Trueform Concrete, Rockaway, N.J.

Design ideas:

- If you want to replicate a roughened stone-like texture along the countertop edges, commercial edge liners are available with textures resembling chiseled stone.

- Apply a low-luster or penetrating sealer to the countertop surface to maintain a natural look. Avoid glossy finishes.

- Choose organic, earth-toned color schemes, such as natural gray, brown or sandy beige.

Polished or Sanded Finish

Polishing or sanding concrete countertop surfaces after they’re cast results in a smooth, flawless finish. The gloss level can range from low luster to ultra-shiny, depending on the degree of polishing.A Countertop Captain Ahab Would Love

Stone Soup Concrete, Florence, Mass

Seamless Island Is Fabricated in One Piece

Hard Topix Precast Concrete, Jenison, Mich.

Countertops Balance Beauty with Function

DC Custom Concrete, San Diego, Calif.

Design ideas:

- For ultra-smooth polished surfaces, cast the countertop in one piece to eliminate seams.

- For the look of white marble or porcelain, use a titanium-white concrete mix containing white silica sand.

- For a more natural, low-luster finish, hand sand the concrete or only polish the surface lightly.

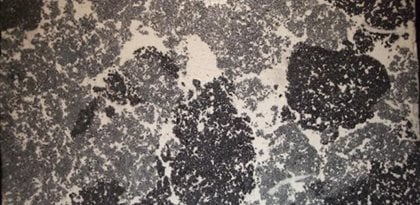

Exposed-Aggregate Finish

Some of the most unique and dramatic concrete countertop finishes can be created by exposing the aggregate. The process begins by seeding the concrete countertop mix with pieces of decorative colored stone or glass. After the countertop is cast, going over the surface with a grinder will expose the aggregate and give it a gem-like luster. For nighttime drama, there are even special glow-in-the dark aggregates available that absorb and store natural and artificial light.Counters Personalized with Colored Glass

Concrete Interiors, Martinez, Calif

Concrete Bartop Enhances Upscale Tavern

Absolute ConcreteWorks, Seattle, Wash.

New Concrete Aggregate Glows in the Dark

Ambient Glow Technology, Pickering, ON

Design ideas:

- Tailor the look to suit your design tastes by using different types and sizes of decorative aggregate. Options include pieces of recycled glass, decorative stone, bits of marble, broken tiles, and seashells.

- The exposed aggregate will be more noticeable if it contrasts with the concrete color, such as using bits of white marble in a charcoal-gray countertop.

- To enhance the gem-like sparkle of exposed aggregate, seal the surface with a high-gloss sealer.