- Pouring Concrete in Hot Weather

- Pouring Concrete in Cold Weather

- Can You Pour Concrete in the Rain?

- Concrete Mix Design

- Types of Admixtures for Concrete

Section Sponsor

Packaged Admixtures

Seasonal Pouring Tips

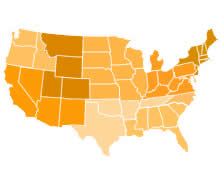

Get guidelines for placing concrete by region and season throughout the U.S.

SELECT A REGION

Hot Weather Concrete Tips for a Crack-Free Summer Pour

How to pour, cool, and cure concrete to beat the summer heat.Summer is often the peak season for outdoor concrete work—and also the time when temperatures are at their highest. When summer temperatures soar, concrete work doesn’t hit pause—it just gets more complicated. Hot weather can accelerate hydration, cause premature drying, and create a cascade of problems that threaten both the strength and lifespan of a concrete project.

For contractors, ready-mix suppliers, and DIYers alike, understanding how heat affects freshly placed concrete is essential for avoiding costly complications later. From cooling techniques and optimized mix designs to smart curing practices and the use of special admixtures, here are some strategies for keeping concrete cool in summer—no matter how high the mercury climbs.

HOW DO HIGH TEMPERATURES IMPACT CONCRETE?

Most of the problems associated with placing concrete in hot weather stem from two key factors: the accelerated rate of cement hydration at elevated temperatures and the rapid evaporation of moisture from the concrete surface.

High temperatures can significantly speed up setting times, leading to premature stiffening, plastic shrinkage cracking, and difficulty achieving a proper finish. These effects are even more pronounced when relative humidity is low and wind speeds are high, as both conditions increase the rate of moisture loss.

According to the American Concrete Institute, the potential problems of placing concrete in hot weather include:

- Increased rate of setting, resulting in greater difficulty with handling, compacting, and finishing.

- Increased evaporation, which can raise the risk of plastic shrinkage cracking and reduce the water available for proper curing.

- Loss of slump and reduced ultimate strength, resulting from adding water to the mix to make it easier to place. (Learn more about the importance of using a low water-cement ratio.)

- Thermal cracking caused by temperature differentials as the surface of the concrete placement cools faster than the interior.

To combat these effects, proper planning and curing are essential. That means cooling the mix, using admixtures, and protecting the concrete from sun and wind during placement and curing.

HOW DO YOU COOL CONCRETE IN SUMMER?

Pouring concrete in hot weather presents unique challenges, but there are several effective strategies you and your ready-mix supplier can use to keep the concrete cool and workable.

To quickly lower the concrete temperature without increasing the water-cement ratio, ready-mix producers can replace a portion of the mixing water with chilled water or ice. Chilled water can reduce the concrete temperature by up to 10° F, while ice can lower it by as much as 20° F. For even greater cooling—especially in extreme conditions—injecting liquid nitrogen directly into the mixer is a measure that can be taken to rapidly drop the mix temperature without compromising quality.

Another strategy is to pre-cool the aggregates before adding them to the concrete mix. Since aggregates make up the majority of the concrete by volume, storing them in the shade or spraying them with water can significantly reduce the overall temperature of the mix.

To prevent rapid heating of the concrete at the jobsite, wet down the subbase before the pour to cool it down, and schedule the job for the early morning or late evening to avoid peak heat. Also use temporary sunshades and windbreaks to shield the placement area from direct sunlight and drying winds. These measures can help minimize surface evaporation, reduce the risk of plastic shrinkage cracking, and improve overall finish quality.

What the Pros Say

“Preplanning is critical when pouring concrete in hot weather. Tracking sun and shade patterns, staging tools and products, and having stamps pre-dusted with release and ready to go are all keys to success.”

— Jeff Hershberger, of Deco-Crete Supply (watch more of his hot weather pour tips)

— Jeff Hershberger, of Deco-Crete Supply (watch more of his hot weather pour tips)

WHAT ARE THE BEST ADMIXTURES FOR HOT-WEATHER CONCRETE?

In hot weather, the right admixtures can be game-changers for keeping concrete workable, strong, and crack-resistant. Success depends on matching each product to the specific challenges you're facing—whether it's rapid setting, excessive moisture loss, or poor workability.

If you need more time to place and finish the concrete, use set-retarding admixtures or hydration stabilizers to slow down the setting process and prevent concrete from stiffening too quickly. For decorative or stamped concrete, consider using delayed-set admixture packets (such as Mini Delayed Set from Fritz-Pak) that can be tossed into the concrete mix onsite. These allow crews to adjust set times mid-project, giving them more flexibility to apply stamps without rushing or risking surface defects.

Mini Delayed Set

Good for step-delay concrete pouring

Mini Delayed Set

Good for step-delay concrete pouring

Rescue-Pak

Contains six of our most effective admixtures

Rescue-Pak

Contains six of our most effective admixtures

Standard Delayed Set

Dry Powdered Admixture

Standard Delayed Set

Dry Powdered Admixture

If you're dealing with slump loss or poor workability, water-reducing admixtures (also known as plasticizers or superplasticizers) can improve the flow of the concrete without increasing the water-cement ratio, helping to maintain strength and reduce shrinkage cracking.

To manage high internal concrete temperatures, incorporate supplementary cementitious materials, like fly ash or slag, into the mix. These reduce the heat of hydration and enhance long-term durability, especially in mass pours or extended placements.

Keep in mind that most hot-weather concreting projects benefit from a combination of these admixtures. When used together, they can effectively control setting time, improve finishability, and boost the overall performance of your concrete—even during intense summer heat.

Learn more about the different types of concrete admixtures.

Watch David Ojeda of Fritz-Pak demonstrate how Mini Delayed Set and Standard Delayed Set admixtures can extend concrete working times on even the hottest days:

HOW TO CURE CONCRETE IN HOT WEATHER

High temperatures and dry, windy conditions can make it difficult to cure fresh concrete properly. The primary issue is rapid moisture loss, which can prevent the concrete from hydrating fully. If the correct moisture balance isn’t maintained throughout the curing process, the concrete may not reach its intended strength and can develop issues such as plastic shrinkage cracking, surface scaling, and reduced durability. Here are some of the most effective methods for keeping concrete cool and preventing it from drying out:

- Spray an evaporation retarder on the surface during finishing to slow moisture loss before curing begins.

- Soon after finishing, apply a membrane-forming compound to seal in moisture. If possible, use a white-pigmented product to reflect sunlight and help keep the surface cooler.

- Apply wet coverings to the surface, such as damp burlap or curing blankets, keeping them continuously moist to prevent drying. For the best results, wet curing should be maintained for at least 7 days.

- Mist or fog the concrete surface regularly, or as often as needed to keep it consistently damp. Misting is often used in conjunction with other curing methods, such as wet coverings, to ensure that the concrete surface remains moist.

- Retain moisture by covering the surface with polyethylene sheeting, making sure it’s properly secured so it won’t mar the surface.

Whatever curing method you choose, it’s important to avoiding pouring concrete during the hottest part of the day, especially if conditions are dry and windy.

Learn more: Concrete Curing Dos and Don’ts for Achieving Maximum Strength

What ACI Says

“If concrete strengths are satisfactory and curing practices are sufficient to avoid undesirable drying of surfaces, the durability of hot weather concrete will not differ greatly from similar concrete placed at normal temperatures.”

— American Concrete Institute, Guide to Hot Weather Concreting

— American Concrete Institute, Guide to Hot Weather Concreting

FREQUENTLY ASKED QUESTIONS

What temperature should concrete be poured at?

The best weather for pouring concrete is when temperatures are moderate (between 50° F and 70° F), humidity is low, and winds are calm. These conditions help to ensure that the concrete cures evenly and consistently, allowing it to develop its full strength and durability.

Can you pour concrete in 100° F weather?

Yes, it’s possible—but it requires careful planning and temperature control. The primary concern in hot weather isn’t just the air temperature, but also the temperature of the concrete itself. If the freshly placed concrete is about 18° F hotter than normal (for example, 88° F instead of 70° F), studies suggest that the 28-day compressive strength may be reduced by as much as 15%, especially if proper curing isn’t maintained.

Ideally, you should place concrete when air temperatures are below 80° F to prevent overheating and premature drying.

How do I make concrete easier to finish in hot weather?

Evaporation retarders can make concrete finishing easier by slowing down moisture loss from the surface during hot, dry, and windy conditions. Another option is to use a concrete finishing aid, like DAY1 from Brickform. These colloidal silica-based products are designed to be applied during the floating and troweling stages to improve workability, extend finishing times, and enhance surface durability. Never sprinkle water onto the surface of the slab in an attempt to make finishing easier. Doing so can weaken the surface, increase permeability, and lead to long-term durability issues like scaling or dusting.

Is concrete poured in hot weather less durable?

Concrete poured in hot weather can be at greater risk of reduced durability due to rapid moisture loss and accelerated hydration. However, when hot-weather concreting is done right—with temperature control, proper curing, and the use of admixtures or supplementary cementitious materials—the final product can be just as durable as concrete placed in milder conditions.

RELATED:

Pouring Concrete in Cold Weather

Seasonal Pouring Tips

Cool Deck for Pools