- What is Concrete Made of

- Pouring Concrete

- Concrete Mix Designs

- Aggregates in Ready-Mix Concrete

- Building Concrete Slabs

- Concrete Testing

- Seasonal Pouring Tips

- Repairing Concrete

- Concrete Repair

- Fixing Decorative Concrete

- How-To Videos

- Concrete Videos

- Applications

- Staining Concrete

- Stamped Concrete

- Concrete Countertops

- Concrete Patios

- Concrete Floors

- Commercial Concrete

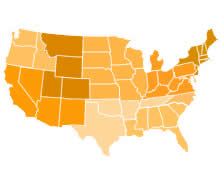

Seasonal Pouring Tips

Guidelines for placing concrete by region and season throughout the U.S.

SELECT A REGION

Pacific Northwest

Southwest

Mountain West

Midwest

Mid-South

Southeast

Mid-Atlantic

Northeast

Weather Related Information:

PACIFIC NORTHWEST SEASONAL POURING TIPS

States Included: Washington, Oregon, Idaho

Climate Overview: If you wait for clear days and dry weather to pour exterior concrete in the Pacific Northwest, you may be idle for a long time. The region receives an average of 40 to 90 inches of rainfall annually. The two major weather influences in the Pacific Northwest are the Pacific Ocean and the Cascade Mountains. Moist air from the northern Pacific comes inland and drops significant rainfall on this region as it contacts the coastal mountains. Most rain occurs along the coast. Snow is rare along the coastal areas, but can quickly accumulate as you gain elevation traveling inland. The biggest issue for exterior concrete pours in this region is moisture from rain, standing water, fog and mist. The eastern areas are drier, and take on more of a high-desert climate.

Climate (December - March): Winters are typically cool and damp for most of this region, with cold and snow only becoming an issue in the higher elevations of the coastal mountains. Long periods of overcast conditions with mist and light rain can occur all winter. The major population centers that run along the coastal valleys rarely see snow, and the ground doesn't freeze until you reach the higher elevations. However, temperatures can hover around freezing for long periods of time, creating freeze-thaw conditions that negatively impact exterior concrete. Exterior concrete is poured year-round in this region.

Mix Designs: This region does not see a hard freeze, but temperatures can fluctuate around the freezing point, causing freeze-thaw cycles to occur many times in a day. This requires the use of cold-weather concrete mix designs, with standard mixes having a minimum compressive strength of 4000 psi. The primary considerations include chemical set accelerators to help the concrete set faster and air-entrainment admixtures to help with freeze-thaw conditions. Air entrainment should be mandatory in all exterior concrete placed in this region. Straight concrete mixes can also be used, as they tend to set faster than hybrid mixes. Using hot water to increase concrete temperature is a common winter practice.

Placement and Curing Practices: The high humidity in this region slows the hydration of concrete, which often minimizes the needs for external curing compounds. Because temperatures below 40 F for prolonged periods can affect concrete strength, cold-weather concreting practices are the norm for exterior pours in the winter, even though temperatures may never get cold enough for a hard freeze. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Proper mix design, placement, and curing are crucial for long-term concrete durability. The primary considerations include blankets for heat retention, heating the mix water, and chemical set accelerators to speed the initial set of the concrete

Special Equipment: Since this region does not see the ground freeze or significant snowfall, there are no special equipment requirements when placing concrete in the winter, with the possible exception of curing blankets.

Climate (April - May): Spring temperatures are cool and conditions can be wet. The threat of freezing temperatures is usually gone by mid-April, but rain is always a consideration.

Mix Designs: Standard mix designs are the norm. Eliminating accelerators and adding fly ash to mixes is normal as the temperatures start to increase.

Placement and Curing Practices: Traditional placement and curing practices are the norm, as temperatures will dictate cold- or warm-weather practices.

Special Equipment: Plastic sheeting to protect against rain.

Climate (June - August): Mild temperatures are the norm for this entire region. Extremely hot temperatures are rare. Rain is unpredictable and can occur at any time of the day in the summer. Moderate to high humidity is normal, aiding placement and curing of exterior concrete.

Mix Designs: Standard mix designs are the norm due to the moderate temperatures and high humidity. When warmer than usual conditions exist, hydration stabilizers and water reducers are commonly used to extend the working life of the concrete without affecting performance. Air-entrainment admixtures should be mandatory in all exterior concrete placed in this region.

Placement and Curing Practices: With the high humidity of this region, wet curing of concrete is common practice. When hot, dry conditions exist, surface evaporative control agents should be available. The use of curing compounds and cure-and-seal chemicals is not as common due to the natural high humidity. Planning around rain is often necessary for exterior concrete pours. Due to exposure of the hardened concrete to freeze-thaw conditions in winter, it is prone to spalling and scaling. Proper water content and finishing are critical for long-term durability.

Special Equipment: Plastic sheeting to protect against rain.

Climate (September - November): Fall temperatures are cool, with the least amount of rainfall. Cold temperatures typically do not become a factor until November. Fall can provide some of the best weather for exterior concrete pours.

Mix Designs: Standard mix designs are the norm. Eliminating fly ash and retarders in mixes is normal as the temperatures start to decrease.

Placement and Curing Practices: Traditional placement and curing practices are the norm, as temperatures will dictate cold- or warm-weather practices.

Special Equipment: Plastic sheeting; curing blankets.

SOUTHWEST SEASONAL POURING TIPS

States Included: California, Arizona, New Mexico, Nevada

Climate Overview: The Southwest is actually comprised of two distinct regions: the coastal plains and inland high deserts. While the high deserts encompass a much bigger geographical footprint, the coastal areas contain the major population centers. One thing both areas have in common is abundant sunshine. The coastal regions enjoy moderate temperatures year-round. Rain averages 15 to 20 inches per year and falls primarily in the winter months of February and March. The farther inland you travel, the warmer the temperatures get, with summer highs reaching 100 F. The larger high desert area is characterized by little rainfall and blazing-hot summer temperatures. Most desert regions average 10 to 12 inches of rainfall annually. Precipitation occurs during winter storms that occur from November to February, and "monsoon" season during July and August.

Climate (December - February): Winters are mild. Most precipitation will fall in this region during these few months. Higher elevations will see snow, while most areas see rain. Day time temperatures are mild and range from 50 F to 70 F. The higher elevation areas of Northern Arizona and New Mexico can see periods of cold weather, but typically they do not last for more than a week, with abundant sun shine right behind. Moderate temperatures and midrange humidity make the winter months a great time for exterior concrete placement in most of these regions.

Mix Designs: With the exception of the high deserts, this region does not see much in the way of harsh weather. Most exterior concrete mix designs have compressive strengths of 3000 psi concrete and need little in the way of additional chemical set accelerators. In colder regions, 4000-psi concrete is often specified and set accelerators and air entrainment may be used if necessary.

Placement and Curing Practices: Moderate temperatures and mid-level winter humidity allow for relatively easy placement and curing of concrete during the winter. For high elevation regions (above 3000 feet), cold-weather concreting practices and the use of curing blankets may be needed when temperatures fall below 40 F at night. The use of water- or solvent-based curing compounds is always recommended to achieve quality concrete. During dry Santa Ana wind conditions, make sure to follow proper curing practices to avoid rapid hydration and shrinkage cracking of the concrete surface.

Special Equipment: Since this region does not see the ground freeze or significant snowfall, there are no special equipment requirements when placing concrete in the winter, with the exception of curing blankets in the colder regions, if needed.

Climate (March - April): For the coastal regions, spring ushers in warmer temperatures but is still mild and pleasant. The high deserts start to experience the first hot weather in late spring, but overall conditions are still favorable for exterior concrete pours. Spring rains may occur for prolonged periods in early spring, but are rare after March.

Mix Designs: Standard mix designs are the norm. Eliminating set accelerators and adding fly ash into mixes is normal as the temperatures start to increase. Air entrainment may be needed in high-elevation areas.

Placement and Curing Practices: Transitional placement and curing practices are the norm, as temperatures will dictate cold- or warm-weather practices.

Special Equipment: Sprayers to apply curing compounds and curing blankets for the rare late snow at higher elevations.

Climate (May - September): Sunny and hot! Mild temperatures are limited to within 10 miles of the coast, with all other regions experiencing hot to extremely hot conditions. Coastal areas will see fog in early summer, but this ends by July. Along with the warmer weather comes blazing sunshine, dry winds, and low humidity. In most areas, summer can be the most demanding time of year to pour exterior concrete.

Mix Designs: When hot conditions exist, hydration stabilizers, fly ash, and water reducers are common admixtures used to extend working life without affecting performance. The use of ice in mix water is also common to cool the concrete during transport. Air entrainment may be needed in high-elevation areas.

Placement and Curing Practices: Hot-weather concreting practices are the norm in the summer months. With some of the highest temperatures in the country, placement and curing of concrete in the summer may require extreme measures. In the hottest desert regions, most concrete placements take place before 10 a.m. On many larger projects, concrete is placed at night or during the early morning hours to avoid the extreme sun and heat of the day. Rapid surface hydration is always a threat, so surface evaporative control agents and curing compounds are common on exterior concrete placements.

Special Equipment: Sprayers to apply curing compounds and surface evaporative control agents.

Climate (October - November): Fall temperatures can still be quite hot. Coastal regions will see temperatures moderate earlier, while the deserts remain very warm. Early winter storms can begin to erupt in the late fall.

Mix Designs: Standard mix designs are the norm. Eliminating fly ash and retarders from mixes is normal as the temperatures start to decrease.

Placement and Curing Practices: Hot-weather concreting practices are in effect well into the fall in most areas of the region.

Special Equipment: Sprayers to apply curing compounds and surface evaporative control agents; plastic sheeting.

MOUNTAIN WEST SEASONAL POURING TIPS

High Mountains / High Plains

States Included: Colorado, Wyoming, Utah, Montana

Climate Overview:

The climate in the Mountain West and High Plains is perhaps more varied than any other climate in the United States and Canada. Elevation dictates much of the climate in this region. High-elevation areas experience cold winters and short summers. The high plains are milder but windy, and the low-elevation river valley areas are milder and wetter. Rainfall averages from under 10 to 20 inches annually in the deserts of Utah and up to 40 to 50 inches in the mountains and valleys of Colorado. While all areas within this region experience snowfall, the amount and severity depend on elevation. The high mountain regions have snow on the ground from October to June, while the more temperate valleys and plains typically do not retain snow very long after a snow event. The Rocky Mountain area features extremes and rapid fluctuations of temperature, wind, and light intensity. Spring can happen suddenly, but so can a late spring snowfall. Summers are often sunny, hot, dry, and short. The high plains regions will experience steady wind in spring and summer, with a high average of sunny days. With the exception of the high-mountain regions, exterior concrete work is preformed year-round with adjustments based on weather.

High Mountains Winter

Climate (Mid October - Early April): This region experiences long winters. The first substantial snowfall typically arrives by the end of October, and snow is usually not gone until May or June. Because of the high average of sunny days and the sun's intensity at high altitudes, south-facing areas lose snow significantly faster than those on the north side or in shadowed areas. During the winter, exterior concrete work typically stops, with the exception of jobs that can afford tenting or other means of raising the ground and air temperatures above freezing. Standard concrete blankets may not be enough in high mountain regions to perform cold-weather concreting. Because of typical deep snow cover, rocky soil, and sunny days, the ground only freezes to an average depth of a few inches in mountain regions. This can be deeper on north-facing slopes. Lower-elevation river valleys in the region may see significantly less snow and milder temperatures, allowing for more favorable exterior concreting conditions.

Mix Designs: Cold-weather concrete mix designs are mandatory for all exterior concrete placed in this region during the winter. The primary considerations include chemical set accelerators to help the concrete set faster and air-entrainment admixtures to help with freeze-thaw conditions. Air entrainment should be mandatory in all exterior concrete placed in this region. Straight concrete mixes can also be used, as they tend to set faster than hybrid mixes. Taking the temperature of the concrete when it arrives at the jobsite is important to ensure it is not too cold and prone to freezing before curing.

Placement and Curing Practices: Cold-weather concreting practices are mandatory for all exterior concrete placed in this region during the winter. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Proper mix design, placement, and curing are crucial for long-term concrete durability. The primary considerations include blankets for heat retention as well as the possibility of tenting in very cold conditions. Curing concrete in these regions usually requires the use of solvent-based cure or cure-and-seal chemicals to avoid freezing. The ready-mix supplier should be consulted far in advance of the concrete pour, since some plants in high-mountain areas shut down for the winter. Also, some states have road restrictions that may create a logistical issue in delivering concrete. Additional travel time can affect concrete performance, especially in very cold temperatures. With terrain in the mountain regions often playing a factor, pumping concrete becomes more common. Proper planning and communication are keys to a successful winter pour.

Special Equipment:

- Sprayers to apply curing compounds

- Ground heaters if the ground is frozen prior to the pour

- Concrete pumps to speed the placement of concrete in cold conditions

- Curing blankets and non-water-based curing compounds

- Tenting

- Proper cold-weather attire for crews pouring and finishing the concrete

High Mountains Spring

Climate (April - June): High-mountain regions typically see a short, wet spring. Often winter transitions directly to summer. Snowfall can occur at any time during the spring months, with wide temperature swings. If pouring exterior concrete during March through May, both winter and spring conditions may exist in a 24- hour period, so plan accordingly and check the extended forecast before pouring.

Mix Designs: Reference High Mountains Winter

Placement and Curing Practices: Reference High Mountains Winter.

Special Equipment: Reference High Mountains Winter

High Mountains Summer

Climate (June - August): Warm days and cool nights are the norm for high-mountain summers. High-intensity sunshine with very low humidity is the norm. Temperatures are mild to cool during the summer season. Late afternoon thunderstorms are common, so exterior concrete pours should be planned for the morning, with rain protection mandatory after the job is complete. Most exterior concrete work takes place during the summer in the high-mountain region.

Mix Designs: Dealing with low humidity and intense sunshine can require the use of admixtures to extend the set time. Hydration stabilizers and water reducers are commonly used to extend the working life of the concrete without affecting performance. Air-entrainment admixtures should be mandatory in all exterior concrete placed in this region.

Placement and Curing Practices: Because of the low humidity in high-mountain regions, rapid surface hydration is common and can be compounded by the intense sunshine and any wind that may be present. It is always a good idea to have a surface evaporative control chemical on hand. The use of curing compounds or cure-and-seal chemicals is highly recommended to minimize shrinkage cracking. These cures need to be applied as soon as possible after finishing is complete to aid in moisture retention. Due to exposure of the hardened concrete to freeze-thaw conditions in winter, it is prone to spalling and scaling. Proper water content and finishing are critical for long-term durability.

Special Equipment: Plastic sheeting to protect concrete from sudden rain showers; sprayers to apply curing compounds and surface evaporative control chemicals.

High Mountains Fall

Climate (Late August - October): As with spring, this season is short and sometimes nonexistent. Snow can start falling in late August or early September, so any exterior concrete work poured during this season should plan for sudden cold weather. The day time temperatures are typically mild, with cold nights. Cold weather protection overnight becomes more important the deeper into the fall season you pour. Scheduling new exterior concrete work can be difficult, since concrete suppliers and installers are typically busy finishing as much work as possible before winter arrives.

Mix Designs: Reference both High Mountains Summer and Winter since this season can have elements of both climates.

Placement and Curing Practices: Reference both High Mountains Summer and Winter since this season can have elements of both climates.

Special Equipment: Reference both High Mountains Summer and Winter since this season can have elements of both climates.

High Plains Winter

Climate (December - March): Winters are generally mild, with average temperatures in the low to mid 40s. Winter precipitation is typically snow, with the heaviest snow occurring later in the winter. North-facing slopes and shaded areas will tend to retain snow for longer periods. The ground does not typically freeze hard or deep in these regions. Exterior concrete placement takes place year-round, with short stoppages for inclement weather or cold temperatures occurring periodically throughout the season.

Mix Designs: Cold-weather concrete mix designs are typically used in these regions, but can be replaced with standard mixes, weather permitting. Primary considerations include accelerators for rapid set (calcium chloride accelerators for standard gray concrete and non-chloride-based accelerators for colored concrete). Straight cement mixes are also used to aid in a faster set time. Taking the temperature of the concrete when it arrives at the jobsite is important to ensure it is not too cold and prone to freezing before curing.

Placement and Curing Practices: Cold-weather concreting practices will be dictated by the weather conditions on the day of the pour, which can range from cold weather to fair weather. The primary consideration is the use of blankets for heat retention. Curing concrete in these regions usually requires solvent-based curing compounds or cure-and-seal chemicals to avoid freezing. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Proper mix design, placement, and curing are crucial for long-term concrete durability. The ready-mix supplier should be consulted far in advance of the concrete pour, since some states have road restrictions limiting vehicle weights allowed on the roads, which may create a logistical issue in delivering concrete. Additional travel time can affect concrete performance, especially in very cold temperatures. Proper planning and communication are keys to a successful winter pour.

Special Equipment: Pouring exterior concrete in the high plains regions in winter typically requires no additional or special equipment. The current weather conditions will dictate any special needs, which may include ground heaters if the ground is frozen prior to the pour, curing blankets, tenting of the pour area, sprayers for applying curing compounds, and cold-weather attire for crews pouring and finishing the concrete.

High Plains Spring

Climate (March - May): This region typically sees a wet and windy spring. Temperatures can swing drastically, with 30 F to 40 F changes in a 24-hour period not uncommon. Very windy conditions can exist, especially in foot hill areas and flat plains regions. In some areas, March and April are the heaviest snow months. If pouring exterior concrete during March though May, both winter and spring conditions may exist, so plan accordingly and check the extended forecast before pouring.

Mix Designs: Reference High Plains Winter.

Placement and Curing Practices: Due to high winds, using surface evaporative retarders along with proper curing chemicals is recommended.

Special Equipment: Reference High Plains Winter.

High Plains Summer

Climate (June - August): Hot days and cool nights are the norm for high plains summers. High-intensity sunshine with very low humidity is the norm. Daytime temperatures can be very warm, with late afternoon thunderstorms and some severe storms common. These storms tend to be more prevalent in early summer. Exterior concrete pours should be planned for the morning, with rain protection mandatory after the job is complete.

Mix Designs: Dealing with low humidity and intense sunshine can require the use of admixtures to extend the set time. Hydration stabilizers and water reducers are commonly used to extend the working life of the concrete without affecting performance. The use of fly ash is also common to help slow set time. Air-entrainment admixtures should be mandatory in all exterior concrete placed in this region.

Placement and Curing Practices: Because of the low humidity in this region, rapid surface hydration is common and can be compounded by the intense sunshine and any wind that may be present. It is always a good idea to have a surface evaporative control chemical on hand. The use of curing compounds or cure-and-seal chemicals is highly recommended to minimize shrinkage cracking. Morning placement of concrete is also common to avoid the heat of the day and afternoon thunderstorms. Pumping concrete for larger pours is also common, to speed the delivery of the concrete to the jobsite in hot weather. Proper water content and finishing are critical for long-term durability.

Special Equipment: Plastic sheeting to protect concrete from sudden rain showers; sprayers to apply curing compounds and surface evaporative control chemicals; concrete pump to help speed concrete placement on larger jobs.

High Plains Fall

Climate (September - November): Moderate temperatures with little precipitation make for good concrete placing conditions. A sudden cold front or snow storm can arrive as early as September, but cold weather is usually not a factor until December. Concrete can typically be placed at any time of the day, and cold weather protection may be needed at night later in the season. Scheduling new exterior concrete work in this region in the fall can be difficult, since concrete suppliers and installers are typically busy finishing as much work as possible before winter arrives.

Mix Designs: Reference high plains summer.

Placement and Curing Practices: Reference high plains summer.

Special Equipment: Reference high plains summer.

MIDWEST SEASONAL POURING TIPS

States Included: Illinois, Iowa, Missouri, Kansas, Nebraska, Minnesota, Wisconsin, North Dakota, South Dakota

Climate Overview:

Although they cover a large geographic area, the states that fall within this region have similar weather patterns. To varying degrees, all areas have cold winters with snow, short springs, cool falls, and hot, humid summers. The farther north you go, the more severe the winters. Wisconsin, Minnesota and the Dakotas usually have snow on the ground for the entire winter. Precipitation ranges from 20 inches annually in the western states to 40 inches in the eastern and southern areas. Gulf of Mexico moisture is a constant, leading to hot, humid summers and snowy overcast winters. The spring and fall provide the most comfortable conditions, but are short in duration. Cold rain can continue into May, with cold temperatures beginning in early October. Exterior concrete work takes place year-round in the southern areas, but is uncommon in the northern areas of this region.

Climate (December - March): Winters are typically cold, damp and overcast. Most precipitation that falls is snow. Ground frost can vary from several inches to none at all depending on where in the region you reside. Exterior concrete is poured year-round with precautions.

Mix Designs: Cold-weather concrete mix designs are mandatory for all exterior concrete placed in this region during the winter. The primary considerations include chemical set accelerators to help the concrete set faster and air-entrainment admixtures to help with freeze-thaw conditions. Air entrainment should be mandatory in all exterior concrete placed in this region. Straight concrete mixes can also be used, as they tend to set faster than hybrid mixes. Using hot water to increase concrete temperature is a common winter practice.

Placement and Curing Practices: Cold-weather concreting practices are mandatory for all exterior concrete placed in this region during the winter. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Proper mix design, placement, and curing are crucial for long-term concrete durability. The primary considerations include blankets for heat retention as well as the possibility of tenting in very cold conditions. Curing concrete in these regions usually requires the use of solvent-based curing compounds or cure-and-seal chemicals to avoid freezing. With cold temperatures, time is a factor, so pumping concrete becomes more common.

Special Equipment:

- Sprayers to apply curing compounds

- Ground heaters if the ground is frozen prior to the pour

- Concrete pumps to speed the placement of concrete in cold conditions

- Curing blankets and non-water-based curing compounds

- Tenting

- Proper cold-weather attire for crews pouring and finishing the concrete

Climate (April - May): Spring temperatures are cool and conditions can be wet. The threat of snow and freezing temperatures is usually gone by mid-April, but rain is always a consideration. Prolonged periods of rain can delay spring exterior concrete projects.

Mix Designs: Standard mix designs are the norm. In northern areas or regions with prolonged cold weather, chemical set accelerators may be used in concrete in the spring to help the concrete set quickly and uniformly. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Air-entrainment admixtures should be mandatory in all exterior concrete placed in this region.

Placement and Curing Practices: Windy conditions can be common in the spring in western portions of this region. Plastic sheeting, surface evaporative control agents, and curing compounds should be available on all exterior pours in the spring. Proper water content and finishing are critical for long-term durability.

Special Equipment: Plastic sheeting to protect concrete from sudden rain showers; sprayers to apply curing compounds and surface evaporative control chemicals.

Climate (June - August): Hot, humid summers are the norm for this entire region. Extreme temperatures are rare. Periodic rain is common, and can occur at any time of the day. Most exterior concrete work takes place during the summer in this region.

Mix Designs: Dealing with high humidity and warm weather can require the use of admixtures to extend the set time. Hydration stabilizers and water reducers are commonly used to extend the working life of the concrete without affecting performance. Air-entrainment admixtures should be mandatory in all exterior concrete placed in this region.

Placement and Curing Practices: With high humidity and hot temperatures, quick placement is the norm for exterior concrete projects. Surface evaporative control agents should be available on all jobs, whether they are used or not. The use of curing compounds and cure-and-seal chemicals is commonplace for most exterior summer pours. Due to exposure of the hardened concrete to freeze-thaw conditions in winter, it is prone to spalling and scaling. Proper water content and finishing are critical for long-term durability.

Special Equipment: Plastic sheeting to protect concrete from sudden rain showers; sprayers to apply curing compounds and surface evaporative control chemicals; concrete pumps for rapid placement in hot conditions.

Climate (September - November): Fall provides the lowest humidity and most stable temperatures for pouring exterior concrete. Frost and freezing temperatures typically do not become a factor until November. Scheduling new exterior concrete work can be difficult, since concrete suppliers and installers are typically busy finishing as much work as possible before winter arrives.

Mix Designs: Hydration stabilizers and water reducers are commonly used to extend the working life of the concrete without affecting performance. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Air-entrainment admixtures should be mandatory in all exterior concrete placed in this region.

Placement and Curing Practices: Surface evaporative control agents should be available on all jobs, whether they are used or not. The use of curing compounds and cure-and-seal chemicals is commonplace for most exterior pours. Proper water content and concrete finishing practices are critical for long-term durability.

Special Equipment: Sprayers to apply surface evaporative control agents and curing compounds; curing blankets; plastic sheeting.

MID-SOUTH SEASONAL POURING TIPS

States Included: Oklahoma, Texas, Arkansas, Tennessee

Climate Overview:

The mid-south climate features humid, hot, long summers and cool winters, with only brief periods of cold weather. Spring and fall are short. Cool winters with temperatures ranging from 40 F and 50 F can sometimes give way to a winter cold front that drops temperatures into the lower 20s. However, these occurrences are usually short lived. Summer temperatures rise to the upper 90s and can exceed 100 F for long periods. Rainfall ranges from 24 inches in the western areas of central Texas to 40 to 50 inches in areas of Arkansas and Tennessee. Spring storms can be severe, with the threat of tornadoes in all areas.

Climate (December - March): Winters are cool. Day time temperatures range from 40 F to 50 F. Prolonged periods of very cold weather are rare. When winter storms do occur, ice and freezing rain is more common than snow. Cool temperatures allow year-round exterior concrete placement.

Mix Designs: Since all areas of this region see freeze-thaw conditions, air entrainment is common on all exterior concrete. Mix designs will have compressive strengths ranging from 3000 to 4000 psi, depending on the final use. The primary considerations include chemical set accelerators to help the concrete set faster and air-entrainment admixtures to help with freeze-thaw conditions. Straight concrete mixes can also be used, as they tend to set faster than hybrid mixes. Using hot water to increase concrete temperature is a common winter practice. Due to high freeze thaw conditions, this region is prone to spalling and scaling concrete. Proper mix design, placement, and curing are crucial for long term concrete durability.

Placement and Curing Practices: Cold-weather concreting practices are mandatory for all exterior concrete placed in this region during the winter. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Proper mix design, placement, and curing are crucial for long-term concrete durability. The primary considerations include blankets for heat retention as well as the possibility of tenting in very cold conditions. Temperatures can vary greatly between day time and night time. Curing concrete in these regions usually requires the use of solvent-based curing compounds or cure-and-seal chemicals to avoid freezing.

Special Equipment:

- Sprayers to apply curing compounds

- Curing blankets and non-water-based curing compounds

- Tenting

- Proper cold-weather attire for crews pouring and finishing the concrete

Climate (April - May): Spring is very short in the Mid-South region. Cool winters change over to hot summers very quickly.

Mix Designs: Standard mix designs are the norm. Eliminating accelerators and adding fly ash into mixes is normal as the temperatures start to increase.

Placement and Curing Practices: Traditional placement and curing practices are the norm, as temperatures will dictate cold- or warm-weather practices.

Special Equipment: Sprayers to apply curing compounds; blankets for the rare late- season cold snap.

Climate (May - October): Hot and humid! Most areas experience hot to extremely hot conditions. Along with the hot weather come winds, especially in the more open spaces of the western states. In most areas, summer can be the most demanding time of year to pour exterior concrete.

Mix Designs: When hot conditions exist, hydration stabilizers, fly ash, and water reducers are common admixtures used to extend working life without affecting performance. The use of ice in mix water is also common to cool the concrete during transport.

Placement and Curing Practices: Hot-weather concreting practices are the norm in the summer months. With the combination of heat and wind, placement and curing of concrete in the summer can require extreme measures. In the hottest western regions, most all concrete placement takes place before 10 a.m. On many larger projects, concrete is placed at night or during the early morning hours to avoid the extreme sun and heat of the day. Rapid surface hydration is always a threat, so surface evaporative control agents and curing compounds are common on exterior concrete placements.

Special Equipment: Sprayers to apply curing compounds and surface evaporative control agents.

Climate (October - November): Because fall temperatures can still be quite warm in this region, hot-weather concreting practices are still necessary until late into the season. Coastal regions will see temperatures moderate earlier, while the deserts remain very warm. Early winter storms may begin in the late fall.

Mix Designs: Standard mix designs are the norm. Eliminating fly ash and retarders in mixes is normal as the temperatures start to decrease.

Placement and Curing Practices: Hot-weather concreting practices are in effect well into the fall in most areas of the region.

Special Equipment: Sprayers to apply curing compounds and surface evaporative control agents; plastic sheeting.

SOUTHEAST SEASONAL POURING TIPS

States Included: North Carolina, South Carolina, Georgia, Mississippi, Louisiana, Alabama, Florida

Climate Overview:

The predominant weather is warm and humid. Precipitation is frequent, and can be heavy. Annual rainfall averages 40 to 60 inches. There is a distinctive wet and dry season for most of this region. The wet season runs from June to October, with the dry season running through the winter into early summer. Frost and winter freezing spells can occur, but do not last long. The farther south you go, the rarer frost and cold weather become. Exterior concrete is poured year-round, but special attention is needed due to extreme summer heat and sudden downpours. This entire region is vulnerable to Atlantic hurricanes during the hurricane season, which runs from June through November.

Climate (December - March): Winters are mild throughout most of this region. This is the dry season and conditions are most favorable during this time of year for exterior concrete work. Temperatures range from 60 F to 80 F, with freezing temperatures very rare. Rain is infrequent, but hit-and-miss rain showers can occur.

Mix Designs: Because of the warm year-round climate, most exterior concrete mix designs have compressive strengths of 3000 psi concrete and need little in the way of additional chemical set accelerators during the winter. In northern areas of the region, 4000-psi concrete is often specified and set accelerators and air entrainment may be used if necessary.

Placement and Curing Practices: Mild temperatures and moderate humidity allow for relatively easy placement and curing of concrete in these regions during the winter. Cold-weather concrete practices are rarely, if ever, used. However, the use of curing compounds is still recommended, especially in the wind-prone coastal areas.

Special Equipment: Since this region has mild winter temperatures, there are no special equipment requirements when placing concrete in the winter.

Climate (March - April): Spring brings increasing humidity and temperatures. Rain can become more frequent, but it is still considered part of the dry season. Temperatures are still moderate, and exterior concrete work is preformed with little concern for extreme weather.

Mix Designs: Standard mix designs are the norm. Adding fly ash and set retarders into mixes is normal as the temperatures start to increase.

Placement and Curing Practices: Hot-weather concreting practices become more critical as the temperatures start to increase.

Special Equipment: Sprayers to apply curing compounds and surface set retarders during hot weather.

Climate (May - September): Hot and humid! Even coastal areas experience hot conditions. Along with the warmer weather comes the tropical monsoon season, with almost daily afternoon downpours of rain, sometimes with heavy winds. In most areas of this region, summer can be the most demanding time of year to pour exterior concrete.

Mix Designs: When hot conditions do exist, hydration stabilizers, fly ash, and water reducers are common admixtures used in this region to extend working life without affecting performance. The use of ice in mix water is also common to cool the concrete during mixing transport.

Placement and Curing Practices: Hot-weather concreting practices are the norm in the summer months. With the high heat and oppressive humidity, placement and curing of concrete may require extreme measures. In most areas, all concrete placement is recommended to take place before 10 a.m. On many larger projects, concrete is placed at night or during the early morning hours to avoid the extreme heat of the day and to allow concrete to set before afternoon rains. Rapid surface hydration is always a threat, so surface evaporative control agents and curing compounds are common on exterior concrete placements.

Special Equipment: Sprayers to apply curing compounds and surface evaporative control agents; plastic sheeting for protection from rain.

Climate (October - November): Fall temperatures can still be quite hot, with high humidity. This is the heart of hurricane season, so constant monitoring of the weather forecast is important since major storms can last for days and do major damage.

Mix Designs: Standard mix designs are the norm. Eliminating fly ash and set retarders in mixes is normal as the temperatures start to decrease.

Placement and Curing Practices: Hot-weather concreting practices are in effect well into the fall in most areas of the region. The use of plastic sheeting for rain protection is also common well into the fall.

Special Equipment: Sprayers to apply curing compounds and surface evaporative control agents; plastic sheeting.

MID-ATLANTIC SEASONAL POURING TIPS

States Included: Pennsylvania, Ohio, Indiana, Michigan, West Virginia, Delaware, Maryland, Virginia, Kentucky

Climate Overview:

The weather pattern is similar for most of the states that fall within this region. To varying degrees, all areas have cold winters with snow, short springs, cool falls, and hot, humid summers. The more coastal and southern states have milder winters, but all areas see snow. Precipitation ranges from 20 inches annually in the western states to 40 inches in the eastern and southern areas. Gulf of Mexico moisture is a constant, leading to the hot, humid summers and snowy overcast winters. Occasional Atlantic storms from the south and winter arctic storms from Canada add to the humidity and constantly changing weather. The spring and fall provide the most comfortable conditions, but are short in duration. Cold rain can continue into May, with cold temperatures beginning in early October. Exterior concrete work takes place year-round in this region, but the weather is always a factor and needs to be monitored closely.

Climate (December - March): Winters are typically cold, damp and overcast in this region. Most precipitation that falls is snow, but it is not typical to have snow on the ground for long durations. Ground frost can vary from several inches to none at all depending on where in the region you reside. Exterior concrete is poured year-round with precautions.

Mix Designs: Cold-weather concrete mix designs are mandatory for all exterior concrete placed in this region during the winter. The primary considerations include chemical set accelerators to help the concrete set faster and air-entrainment admixtures to help with freeze-thaw conditions. Air entrainment should be mandatory in all exterior concrete placed in this region. Straight concrete mixes can also be used, as they tend to set faster than hybrid mixes. Using hot water to increase concrete temperature is a common winter practice.

Placement and Curing Practices: Cold-weather concreting practices are mandatory for all exterior concrete placed in this region during the winter. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Proper mix design, placement, and curing are crucial for long-term concrete durability. The primary considerations include blankets for heat retention as well as the possibility of tenting in very cold conditions. Curing concrete in these regions usually requires the use of solvent-based curing compounds or cure-and-seal chemicals to avoid freezing. With cold temperatures, time is a factor, so pumping concrete becomes more common.

Special Equipment:

- Sprayers to apply curing compounds

- Ground heaters if the ground is frozen prior to the pour

- Concrete pumps to speed the placement of concrete in cold conditions

- Curing blankets and non-water-based curing compounds

- Tenting

Climate (April - May): Spring temperatures are cool and conditions can be wet. The threat of snow and freezing temperatures is usually gone by mid-April, but rain is always a consideration. Conditions tend to be milder and drier from east to west within the region. Prolonged periods of rain can delay spring exterior concrete projects.

Mix Designs: Standard mix designs are the norm. In northern areas or regions with prolonged cold weather, chemical set accelerators may be used in concrete in spring pours to help the concrete set quickly and uniformly. Air-entrainment admixtures should be mandatory in all exterior concrete placed in this region.

Placement and Curing Practices: Windy conditions can be common in the spring in western portions of this region. Plastic sheeting, surface evaporative control agents, and curing compounds should be available on all exterior pours in the spring. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Proper mix design, placement, and curing are crucial for long-term concrete durability.

Special Equipment: Sprayers to apply surface evaporative control chemicals and curing compounds; plastic sheeting.

Climate (June - August): Hot, humid summers are the norm for this entire region. Extreme temperatures are rare. Rain is unpredictable and can occur at any time of the day. Most exterior concrete work takes place during the summer in this region.

Mix Designs: Dealing with high humidity and warm weather can require the use of admixtures to extend the set time. Hydration stabilizers and water reducers are commonly used to extend the working life of the concrete without affecting performance. Air-entrainment admixtures should be mandatory in all exterior concrete placed in this region.

Placement and Curing Practices: With high humidity and hot temperatures, quick placement is the norm for exterior concrete projects. Surface evaporative control agents should be available on all jobs, whether they are used or not. The use of curing compounds and cure-and-seal chemicals is commonplace for most exterior summer pours. Due to exposure of the hardened concrete to freeze-thaw conditions in winter, it is prone to spalling and scaling. Proper water content and finishing are critical for long-term durability.

Special Equipment: Plastic sheeting to protect concrete from sudden rain showers; sprayers to apply curing compounds and surface evaporative control chemicals; concrete pumps for rapid placement in hot conditions.

Climate (September - November): Fall provides the lowest humidity and most stable temperatures for pouring exterior concrete. Frost and freezing temperatures typically do not become a factor until November. Scheduling new exterior concrete work can be difficult, since concrete suppliers and installers are typically busy finishing as much work as possible before winter arrives.

Mix Designs: Hydration stabilizers and water reducers are commonly used to extend the working life of the concrete without affecting performance. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Air-entrainment admixtures should be mandatory in all exterior concrete placed in this region.

Placement and Curing Practices: Surface evaporative control agents should be available on all jobs, whether they are used or not. The use of curing compounds and cure-and-seal chemicals is commonplace for most exterior pours. Proper water content and concrete finishing practices are critical for long-term durability.

Special Equipment: Sprayers to apply surface evaporative control agents and curing compounds; curing blankets; plastic sheeting.

NORTHEAST SEASONAL POURING TIPS

States Included: Maine, Vermont, New Hampshire, Massachusetts, Rhode Island, Connecticut, New York, New Jersey

Climate Overview:

This region has four very distinct seasons. There are considerable temperature variations between the moderate coastal areas and the higher inland areas, but the limiting factor in all areas are cold temperatures. Precipitation is evenly distributed throughout the seasons, with snow falling in the winter and rain in the other seasons. Average annual precipitation ranges from 30 to 50 inches. Spring is typically cool and short, and summers are hot and humid. Summers are cooler in the higher inland mountain regions. Fall can have warm days and cool nights, but freezing temperatures are not an issue in most areas until mid-November. Winters are long, with heavy snowfall and ice in most areas. Most weather approaches from the west, with the occasional coastal "Noreaster" winter storm coming from the south, dropping heavy rain and snow on coastal regions. Weather plays a major role in exterior concrete placement in all seasons in this region.

Climate (December - March): This region experiences long and cold winters. Snow is prevalent and can be on the ground for most of the season. The ground freezes hard in most areas in the Northeast. Coastal areas can be milder than the inland river valleys and mountains, but not different enough to alter concrete practices. Most residential exterior concrete placement is suspended during the winter, with exterior commercial concrete placement taking place year-round.

Mix Designs: Cold-weather concrete mix designs are mandatory for all exterior concrete placed in this region during the winter. The primary considerations include chemical set accelerators to help the concrete set faster and air-entrainment admixtures to help with freeze-thaw conditions. Air entrainment should be mandatory in all exterior concrete placed in this region. Straight concrete mixes can also be used, as they tend to set faster than hybrid mixes. Using hot water to increase concrete temperature is a common winter practice.

Placement and Curing Practices: Cold-weather concreting practices are mandatory for all exterior concrete placed in this region during the winter. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Proper mix design, placement, and curing are crucial for long-term concrete durability. The primary considerations include blankets for heat retention as well as the possibility of tenting in very cold conditions. Since the ground freezes hard, using ground heaters to thaw the ground may be necessary for winter pours. Curing concrete in these regions usually requires the use of solvent-based curing compounds or cure-and-seal chemicals to avoid freezing. With cold temperatures, time is a factor, so pumping concrete becomes more common. The ready-mix supplier should be consulted far in advance of the concrete placement, since some states have road restrictions that may create a logistical issue in delivering concrete. Proper planning and communication are keys to a successful winter pour.

Special Equipment:

- Sprayers to apply curing compounds

- Ground heaters if the ground is frozen prior to the pour

- Concrete pumps to speed the placement of concrete in cold conditions

- Curing blankets and non-water-based curing compounds

- Tenting

- Proper cold-weather attire for crews pouring and finishing the concrete

Climate (April - May): Spring is very short in the Northeast. Temperatures are cool and conditions can be wet. The threat of snow and freezing temperatures is usually gone by mid-April, but rain is always a consideration. Variations can be found within the region in the spring, as the coastal regions can be much milder than the higher northern mountains.

Mix Designs: Because the ground will stay cold longer, chemical set accelerators are often used in concrete in the spring to help the concrete set quickly and uniformly.

Placement and Curing Practices: Windy and wet conditions can be common. Plastic sheeting, surface evaporative control agents, and curing compounds should be available on all exterior pours in the spring.

Special Equipment: Plastic sheeting; sprayers to apply curing compounds and surface evaporative control chemicals.

Climate (June - August): Hot, humid summers are the norm for much of the Northeast. Extreme temperatures are rare. Periodic rain is common, and can occur at any time of the day. Most exterior concrete work takes place during the summer in the high mountain region.

Mix Designs: Dealing with high humidity and warm weather can require the use of admixtures to extend the set time. Hydration stabilizers and water reducers are commonly used to extend the working life of the concrete without affecting performance. Air-entrainment admixtures should be mandatory in all exterior concrete placed in this region.

Placement and Curing Practices: With high humidity and hot temperatures, quick placement is the norm for exterior concrete projects. Surface evaporative control agents should be available on all jobs, whether they are used or not. The use of curing compounds and cure-and-seal chemicals is commonplace for most exterior summer pours. Due to exposure of the hardened concrete to freeze-thaw conditions in winter, it is prone to spalling and scaling. Proper water content and finishing are critical for long-term durability.

Special Equipment: Plastic sheeting to protect concrete from sudden rain showers; sprayers to apply curing compounds and surface evaporative control chemicals.

Climate (September - November): Fall typically experiences the most stable weather conditions of the year for pouring exterior concrete. The humidity is low, and the days are warm with cool nights. Frost and freezing temperatures can start to become a factor later in the season. Scheduling new exterior concrete work can be difficult, since concrete suppliers and installers are typically busy finishing as much work as possible before winter arrives.

Mix Designs: Hydration stabilizers and water reducers are commonly used to extend the working life of the concrete without affecting performance. Due to extensive freeze-thaw conditions, this region is prone to spalling and scaling concrete. Air-entrainment admixtures should be mandatory in all exterior concrete placed in this region.

Placement and Curing Practices: Surface evaporative control agents should be available on all jobs, whether they are used or not. The use of curing compounds and cure-and-seal chemicals is commonplace for most exterior pours. Proper water content and concrete finishing practices are critical for long-term durability.

Special Equipment: Sprayers to apply surface evaporative control agents and curing compounds; curing blankets; plastic sheeting.