- Cold Weather Concrete Home

- Why is Cold Weather a Problem?

- Dos and Don'ts When Placing Concrete in Cold Weather

- Cold Weather Curing Methods

- Can You Pour Concrete in the Rain?

- Related Information:

- Sealing Concrete in Cold Weather: Advice from technical expert Chris Sullivan

- Admixtures for Cold-Weather Concreting

- How to Melt Ice on Concrete Without Causing Damage

- Winterizing Concrete Driveways, Patios & More

- Hot Weather Concreting

Section Sponsor

Packaged Admixtures

Seasonal Pouring Tips

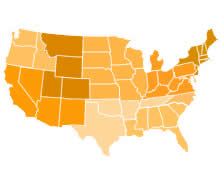

Get guidelines for placing concrete by region and season throughout the U.S.

SELECT A REGION

Guide to Cold Weather Concrete Mix Design

Learn about essential strategies and cold weather additives that can help fresh concrete cure properly during winter conditions.By Anne Balogh, ConcreteNetwork.com

When temperatures drop, concrete faces more than just slower setting times—it’s at risk of freezing, cracking, and losing strength before it fully cures. For both contractors and do-it-yourselfers, understanding how to adjust mix designs for cold weather is essential to maintaining durability and long-term performance.

By reducing the water content, using chemical accelerators, and making a few other adjustments, you can create a mix that stands up to winter’s chill. This guide breaks down the key components of a cold weather concrete mix, explores additives that help prevent freezing, and shares practical strategies to ensure your concrete cures properly even in subfreezing conditions.

Why is pouring concrete in cold weather a concern?

Placing concrete in cold weather is a concern for many contractors because low temperatures can significantly impact the curing process and reduce concrete’s overall strength.

If concrete freezes during the curing process, it can lead to serious problems like cracking and lower compressive strengths. Cold temperatures (below 40°F) can halt the hydration process, preventing the cement from properly bonding with water. If the water in the mix freezes, it can expand and cause internal cracking within the concrete matrix. This early freezing may also reduce the concrete’s strength by as much as 50% of its intended design capacity. Additionally, improperly cured concrete becomes more vulnerable to freeze-thaw cycles, moisture penetration, and structural stress over time.

What can you put in concrete to keep it from freezing?

To keep concrete from freezing and help it cure properly in cold weather, several additives can be used in the mix, including accelerating admixtures, air entrainers, and antifreeze agents.

The most commonly used admixture in cold weather mixes is calcium chloride, which accelerates curing by speeding up the rate of cement hydration. This helps the concrete gain strength faster, reducing the risk of damage from freezing during early curing. However, because calcium chloride can cause corrosion of steel reinforcement, non-chloride accelerators, like Fritz-Pak NCA, are often used in situations where corrosion is a concern.

Air-entraining admixtures are also frequently used to enhance the concrete’s resistance to freeze-thaw cycles. These work by introducing tiny air bubbles into the mix, providing additional internal space for expansion if water turns to ice within the concrete.

While accelerating admixtures help concrete resist freezing, they do not completely prevent it. That’s why antifreeze agents are sometimes added to the mix. Unlike accelerators, which speed up setting and hardening, antifreeze admixtures lower the freezing point of water, allowing concrete to be placed and cured at subzero temperatures without relying on external heat or insulation. In some cases, a combination of accelerators and antifreeze agents is used to achieve the best results in cold conditions. This approach helps keep projects on schedule and ensures durable concrete even in freezing weather.

What the Pros Say

“Accelerating admixtures do not prevent concrete from freezing, so their use does not preclude the requirements for appropriate curing and protection.”

What is a winter concrete mix?

A winter concrete mix is specifically designed to ensure proper setting and curing in cold weather conditions. The goal is to prevent freezing, accelerate curing, and maintain strength despite low temperatures. In addition to the use of accelerating admixtures to speed up the hydration process, key cold weather mix adjustments include:

- The use of preheated water and aggregates to raise the initial temperature of the mix, promoting early strength development.

- A higher cement content or the use of Type III (high-early-strength) cement, which hydrates more rapidly and generates additional heat during curing.

- Limiting or avoiding the use of fly ash or slag, since these supplementary materials slow down setting and generate less internal heat.

- Reducing the water-cement ratio to minimize the risk of freezing and improve overall durability.

What the Pros Say

“As cold weather settles in, you should be thinking about how to adjust your concrete mixtures. For every 10°F drop in temperature, concrete set times increase about 45 minutes. One of the best ways to ensure that your concrete is ready to take out of the form sooner in cold weather is to use an accelerator.”

— Fritz-Pak Corp., “Tips & Tricks For Pouring Concrete in Cold Weather”

— Fritz-Pak Corp., “Tips & Tricks For Pouring Concrete in Cold Weather”

Strategies for placing cold weather concrete

Even if you use accelerating admixtures to speed up early strength gain, protecting concrete from freezing temperatures during the initial curing stage is essential. Without adequate protection from the cold, freshly placed concrete can suffer permanent damage, reducing its strength and durability.

Before pouring a winter concrete mix, always check the temperature of the subgrade where it will be placed. A frozen or excessively cold base can quickly draw heat from the mix, slowing hydration and increasing the risk of freezing. Preheating the ground using portable heaters or covering it with thermal blankets can help warm the surface and create better curing conditions.

Once the concrete is placed, keep it above freezing—ideally above 40°F—for at least 24 to 48 hours so it can develop sufficient strength. During this time, the concrete should be protected from cold air, wind, and moisture loss. Effective methods include insulating blankets to retain heat, windbreaks to block drafts, and heated enclosures to maintain a controlled curing environment. In extreme cold, you may need to combine multiple protection strategies to ensure the concrete cures properly and achieves the desired performance.

Learn more: Pouring Decorative Concrete in Cold Weather

What the Pros Say

“Concrete placed during cold weather, protected against freezing, and properly cured for a sufficient length of time has the potential to develop higher ultimate strength and greater durability than concrete placed at higher temperatures.”

— American Concrete Institute, “Guide to Cold Weather Concreting”

— American Concrete Institute, “Guide to Cold Weather Concreting”

Will concrete set in cold weather?

Yes, but the curing process slows down considerably. To ensure proper strength development, it’s essential to manage conditions carefully. Using a winter mix and maintaining warmth around the concrete after placement—through insulation or heated enclosures—can help it cure successfully even in cold conditions. With the right precautions, not only will the concrete set properly, it may also achieve greater long-term durability and improved resistance to thermal cracking compared to concrete poured in hot weather.

Learn more about cold weather concrete curing.

David Ojeda of Fritz-Pak demonstrates how their non-chloride accelerator can speed up the set time of cold weather concrete by comparing three different concrete mixes: a control mix containing only cement, sand, and water and mixes with 1% and 2% doses of NCA.

MORE WAYS TO PROTECT CONCRETE IN WINTER

- Warm the subgrade before placement using heaters or thermal blankets.

- Use a winter concrete mix containing accelerating admixtures.

- Maintain a concrete temperature above 40°F for at least 24 to 48 hours after placement.

- Use insulating blankets, windbreaks, or heated enclosures to retain heat and control curing conditions.