- Cold Weather Concrete Home

- Why is Cold Weather a Problem?

- Dos and Don'ts When Placing Concrete in Cold Weather

- Cold Weather Curing Methods

- Can You Pour Concrete in the Rain?

- Related Information:

- Sealing Concrete in Cold Weather: Advice from technical expert Chris Sullivan

- Admixtures for Cold-Weather Concreting

- How to Melt Ice on Concrete Without Causing Damage

- Winterizing Concrete Driveways, Patios & More

- Hot Weather Concreting

Section Sponsor

Packaged Admixtures

Seasonal Pouring Tips

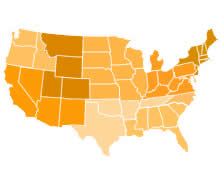

Get guidelines for placing concrete by region and season throughout the U.S.

SELECT A REGION

Cold Weather Concrete Curing Tips for Strong, Durable Slabs

Learn useful strategies for preserving concrete strength and durability when temperatures drop below ideal conditions.By Anne Balogh, ConcreteNetwork.com

Concrete construction doesn’t grind to a halt when cold weather sets in—but curing the concrete properly becomes much more complicated. Once temperatures dip below 40°F, the chemical reaction responsible for hardening concrete slows dramatically, and the water in the mix is at risk of freezing before the concrete gains sufficient strength. This can result in cracking, poor bonding, and reduced long-term durability.

Add to that the difficulties of maintaining consistent heat, retaining moisture, and monitoring internal temperatures, and it’s clear: successful curing of concrete in cold weather demands careful planning and vigilant oversight. Here, we share the most effective procedures, materials, and monitoring techniques to ensure your winter concrete achieves optimal strength and durability.

Why is curing concrete in cold weather a challenge?

Because low temperatures slow or disrupt hydration—the chemical process that allows concrete to gain strength and durability—curing concrete in winter presents several challenges. If the concrete temperature drops below 32°F before hydration is complete, the mix water can freeze and expand, leading to internal stress and cracking. Concrete that cures too slowly or freezes prematurely may never reach its intended strength, compromising its long-term integrity.

In addition, cold conditions prolong setting times, which can delay finishing operations and increase labor costs. Attempting to speed up the process or curing the concrete inadequately can lead to surface defects such as delamination or spalling—especially if the concrete is exposed to freeze-thaw cycles before reaching sufficient strength.

Maintaining optimal curing conditions in cold weather also requires more intensive protection and monitoring. This includes the use of insulation, heating systems, and temperature sensors—all of which add complexity and cost to the project.

What the Pros Say

“In any process where water is involved, crossing the freezing mark can be a deal-breaker. That is the case for curing concrete, which needs to happen above freezing. Failure to adhere to this rule will result in curing that takes significantly longer—and possibly concrete that prematurely fails.”

— Pete Haug, PE, and Todd Rudolph, PE, Ayres Associates Inc.

— Pete Haug, PE, and Todd Rudolph, PE, Ayres Associates Inc.

How cold is too cold to pour concrete?

Pouring concrete becomes risky when ambient temperatures fall below 40°F within the first 24 hours after placement—the threshold where cold weather concreting practices should begin. However, it's generally considered too cold to pour concrete without special precautions when outdoor temperatures drop below 20°F.

To help minimize freezing risk, pour concrete during the warmest part of the day, usually between 10 a.m. and 2 p.m. Pouring earlier in the day also allows more time for the concrete to gain initial strength before nighttime temperatures drop.

Can concrete cure in freezing temperatures?

Yes, but only if protective measures are taken. Without insulation or heat, water in the mix can freeze, halting hydration and causing internal damage. If temperatures drop below 20°F, it’s best to wait until they rise to an acceptable level before placing concrete.

How do I keep concrete warm while it cures?

There are a number of methods you can use to keep concrete warm as it cures—ideally at a temperature above 40°F. The best method for maintaining this temperature depends on several factors, including ambient conditions (colder weather requires more intensive heating), project size, curing duration, and the thickness of the concrete, as thicker slabs retain heat better than thinner ones.

Common options include:

- Covering the newly poured concrete with insulating blankets. Because concrete produces heat during the chemical reaction of curing, insulated blankets can be very effective at maintaining proper curing temperatures and preventing the surface from freezing.

- Constructing temporary, heated enclosures or tents to create a controlled curing environment. This strategy is especially useful for vertical pours or large-scale projects.

- Setting up windbreaks to help maintain a warmer microclimate around the curing concrete and to prevent rapid moisture loss.

- Warming the water and aggregates before mixing to help raise the initial temperature of the concrete.

Keep in mind that some methods, such as heated enclosures, can be more expensive and labor-intensive than others, so your choice may also depend on your budget and available resources.

What the Pros Say

“Concrete placed during cold weather will develop sufficient strength and durability when it is properly proportioned, produced, placed, and protected. The necessary degree of protection increases as the ambient temperature decreases.”

— American Concrete Institute, “Guide to Cold Weather Concreting”

— American Concrete Institute, “Guide to Cold Weather Concreting”

When to use concrete blankets

Concrete curing blankets are insulated coverings designed to prevent freezing and maintain optimal temperatures for effective curing in cold weather. They are typically used when ambient temperatures fall below 40°F and are especially important during the first 24 to 48 hours after placement, when concrete is most vulnerable to temperature fluctuations.

Immediately after pouring the concrete, place the blankets over the entire surface, securing them with weights or sandbags to prevent shifting. If the concrete is maintained at approximately 50°F, the blankets can generally be removed after two days.

Curing blankets come in various types, each suited to specific project needs, weather conditions, and budget constraints. Insulated thermal blankets, typically made of foam, fiberglass, or polyester insulation, work by trapping heat and shielding the concrete surface from cold air. Heated blankets feature built-in electric heating elements that warm the concrete to accelerate curing. These are particularly effective in extreme cold or for thawing frozen ground before the pour.

When to use enclosures and concrete heaters

If the forecast predicts temperatures below 32°F, or if insulating blankets alone can’t maintain internal concrete temperatures above 50°F, enclosures and concrete heaters become essential. They help prevent the mix water from freezing before the concrete gains strength and are especially valuable during extended cold spells, providing a stable curing environment.

Indirect-fired heaters (which warm the air without introducing combustion gases) or hydronic heaters (systems that circulate hot water through hoses or pipes) are ideal for maintaining internal concrete temperatures between 50°F and 70°F—the optimal range for hydration and strength development.

Note that when using heated air inside an enclosure, the concrete surface may dry out too quickly, increasing the risk of plastic shrinkage cracking. To prevent this, incorporate moisture-retaining methods such as fogging, steam, wet burlap, or vapor barriers. Also avoid directing heat straight onto the concrete surface, as this can lead to thermal cracking or uneven drying.

Winter Curing FAQs

Should I use a different concrete mix in winter?

Yes! In winter, a mix with a lower water-cement ratio and containing non-chloride accelerators can go a long way in promoting faster strength gain and reducing the risk of freezing. Using hot water for mixing and storing aggregates in a warm area before use will also help maintain a higher initial temperature.

Learn more: Guide to Cold Weather Concrete Mix Design

How long does concrete take to cure in cold weather?

In cold conditions, concrete curing slows significantly. When temperatures fall below 40°F, the initial set time can take up to twice as long as it would in warmer weather. Under ideal conditions, concrete typically reaches 70% of its compressive strength within 7 days, but at temperatures below 50°F, this process may take 14 days or longer.

Can I pour concrete on frozen ground?

It’s never a good idea to pour concrete directly onto frozen ground because it can compromise its structural integrity. Even if the air temperature is above freezing, the cold ground can rapidly cool the concrete mix, slowing down the curing process. What’s more, when the subgrade thaws, it can shift unevenly, leading to settlement and cracking.

To prevent these problems, remove all ice and snow from the pour site and thaw the subgrade using ground heaters or heated blankets until it reaches a uniform temperature above freezing. Immediately before the pour, insulate the ground with polystyrene foam boards or thermal blankets to prevent it from drawing heat away from the fresh concrete.

Mike Day, owner of Day’s Concrete Floors in Maine, shares expert tips for pouring and finishing a concrete slab in below-freezing temperatures, drawing on his years of experience placing concrete in a cold climate. His strategies include monitoring weather conditions before the pour, insulating the subbase with styrofoam, and using hot water and an accelerator in the concrete mix.

How do I monitor curing temperatures?

One of the more challenging aspects of curing concrete in cold weather is the need to monitor the concrete temperature throughout the process. During the first 48 to 72 hours after concrete placement, it’s critical to maintain a concrete temperature above 40°F—the minimum threshold for effective hydration and early strength development. To track curing temperatures, common methods include:

- Manual probes and thermometers, which are inserted into the concrete or placed in sleeves to measure internal temperatures at specific points.

- Infrared thermometers, which are useful for quick, non-contact surface temperature readings.

- Embedded sensors installed directly in the concrete to continuously monitor internal temperatures. These often integrate with software to estimate real-time strength gain based on maturity models.

For the most accurate results, using a combination of these tools is often the best approach. This helps to ensure that curing conditions stay within the ideal range for proper hydration and early strength development.

TEMPERATURE GUIDELINES FOR COLD WEATHER CURING

| Temperature Range | Risk Level | Recommended Action |

|---|---|---|

| Above 40°F (4°C) | Low | Standard curing practices are sufficient |

| 32°F to 40°F (0 to 4°C) | Moderate | Use insulated blankets and monitor concrete temperatures |

| 20°F to 32°F (-6 to 0°C) | High | Use heated enclosures or hydronic heaters |

| Below 20°F (-6°C) | Very high | Delay the pour or use a combination of advanced heating and monitoring techniques |