If you think you’ve mastered the art of concrete countertop making, try tackling a project where the countertop slab is over 10 feet long and weighs as much as 2,000 pounds. It can be done, but not without making some adjustments to your normal casting and installation process. Faced with their own super-sized countertop projects, these contractors came up with a few tricks to ensure a successful outcome, from using special mix designs to devising inventive lifting and transport systems. Read on to learn more.

Trick 1: Use extra reinforcement

At nearly 17 feet long and weighing in at about 1,700 pounds, Stone Soup Concrete has dubbed this single-piece concrete countertop the White Whale. To prevent any deflection during installation, they reinforced the 2 ½-inch-thick countertop with two layers of wire mesh, top and bottom. Learn the other tricks they used to precast the countertop in their shop, then deliver it to its home.

Trick 2: Use a lightweight concrete mix

Completely seamless, this 11- by 5 ½-foot concrete kitchen island was cast in one piece. To keep the weight at 750 pounds, David Eerdmans and Drew Bleeker of Hard Topix Precast Concrete used a lightweight GFRC mix. A wheeled cart was then used to transport the island from the shop to the jobsite. See how it was done.

Trick 3: Hoist the countertop into place

Unlike typical concrete countertops, which rest squarely on the cabinetry below, this contemporary kitchen required a 9-foot free span of concrete as part of the island. To help minimize the lifting and transporting of the piece, which weighed a hefty 2,000 pounds, contractor DC Custom Concrete precast it onsite, then lifted it into place using the ceiling beams above to hoist it up.

Trick 4: Make a custom support leg

This 10-foot by 32-inch concrete bartop was too large to be supported by the base wall. For a unique and stylish solution, contractor Surfacing Solutions made a decorative corbel-shaped concrete support that matches the curves and colors in the countertop.

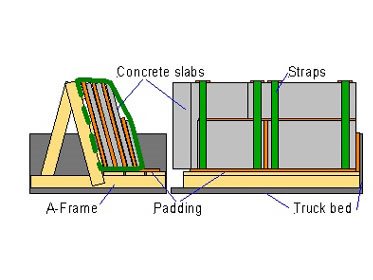

Trick 5: Use A-frames for transport

How can you securely transport precast countertops to the installation site and minimize the risk of cracking or chipping? Jeff Girard of The Concrete Countertop Institute suggests using A-frames or L-frames to support and secure the slabs, along with plenty of padding.

Return to Concrete Countertops