- Concrete joints home

- Isolation joints

- Construction joints

- Contraction joints

- Locating & Filling Joints in Concrete Slabs

- Be active in deciding where to place control joints

- Joints in commercial floors

- Sealing joints- Tips for sealing and filling joints

- Related Information:

- How to build high-quality slabs on grade

- Groover tools for forming joints

Types of Joints in Concrete Slabs

Properly creating and locating joints keeps concrete looking its bestConcrete is not a ductile material—it doesn't stretch or bend without breaking. That's both its greatest strength and greatest weakness. Its hardness and high compressive strength is why we use so much of it in construction. But concrete does move—it shrinks, it expands, and different parts of a building move in different ways. This is where joints come into play.

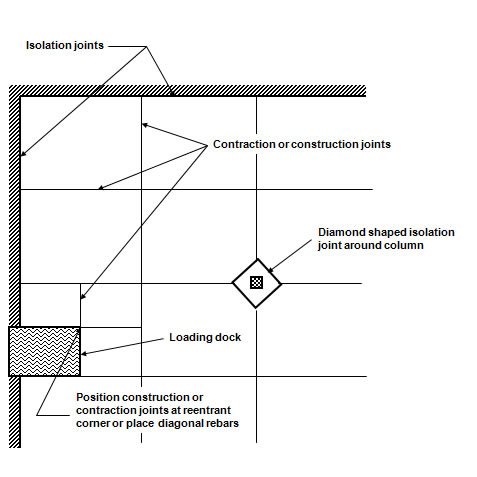

Although many building elements are designed and built with joints, including walls and foundations, we'll limit this discussion to joints in concrete slabs. Here's an overview of the types of joints, their function, and tips for locating and installing joints.

Need help with your project? Find concrete contractors near me.

The Purpose of Joints in Concrete Slabs

As concrete moves, if it is tied to another structure or even to itself, we get what's called restraint, which causes tensile forces and invariably leads to cracking. Restraint simply means that the concrete element (whether it's a slab or a wall or a foundation) is not being allowed to freely shrink as it dries or to expand and contract with temperature changes or to settle a bit into the subgrade (see Subgrades and Subbases).

Joints allow one concrete element to move independently of other parts of the building or structure. Joints also let concrete shrink as it dries—preventing what's called internal restraint. Internal restraint is created when one part of a slab shrinks more than another, or shrinks in a different direction. Think how bad you feel when part of you wants to do one thing and another part wants to do something else! Concrete feels the same way.

In slabs, there are three types of joints:

-

Isolation joints (also sometimes functioning as expansion joints)

-

Construction joints (which can also function as contraction joints)

-

Contraction joints (also sometimes called control joints)

Decorative Joints

A cleanly sawed joint detracts very little from the appearance of a stamped slab. Super-Krete International

Decorative concrete flatwork still needs joints to prevent cracking, which will be even less acceptable than in typical gray concrete. Isolation joints and construction joints in decorative concrete are exactly the same as with any other concrete.

Here are a few tips for making contraction joints in decorative concrete:

- Don't confuse a stamped pattern or an engraved pattern with a joint-stamped patterns and engraving cuts are not deep enough to create the weakened plane for a contraction joint. Make sure the joint depth is at least ¼ the thickness of the slab.

- Spacing and layout of joints for stamped concrete is identical to any other type of concrete.

- For stamped concrete, if the pattern has straight lines, such as slate, brick, or wood patterns, cut your joints to follow the stamped pattern as much as possible. Joints can vary in location a few inches or even a foot or two without leading to cracks. Some stamping contractors use custom-fabricated chisels to cut joints into the stamped pattern.

- For fieldstone or cobblestone patterns, a joint cut to follow the stamped pattern is unlikely to function properly, since shrinkage movement is not always perpendicular to the joint. Any movement parallel to the joint would likely lock the joint, leading to uncontrolled cracking.

- With stamped concrete, perhaps the best way to cut joints is with a cutoff saw. The irregular surface makes a rolling saw difficult to control. For tips on this, check out Bob Harris's video or get a copy of his Guide to Stamped Concrete-joints are covered in Chapter 23.

- Saw-cut contraction joints are ideal for decorative concrete because the joint is narrower and cleaner than a tooled joint.

- Early-entry saws make a nice, clean cut for decorative concrete joints. Soff-Cut's 150D saw is designed for decorative cuts.

- Soff-Cut also makes a beveled blade that is used on the second day to turn a typical saw cut joint (or early entry joint) into a decorative joint. Read more about Soff-Cut's Ultra Early Entry Concrete Cutting Saws and Diamond Blades.

- For bonded overlays, cut joints exactly to match the joints in the base slab. No additional joints are needed.

- For unbonded toppings, ACI 360R-06 recommends the following: "For a thin, unreinforced, unbonded topping slab, additional joints should be considered between the existing joints in the bottom slab to help minimize the curling stress in the topping slab. The topping slab can have high curling stress due to the bottom slab being a hard base for the topping slab. Also, any cracks in the base slab that are not stable should be repaired to ensure they will not reflect through into an unreinforced topping slab."

Jointless Slabs

This topping has no joints and no cracks thanks to a high dose of structural synthetic fibers. Forta Corp.

Although for most applications contraction joints are essential, there are techniques that allow elimination or reduction of the number of joints.

- High doses of "structural" synthetic fibers (also called macro polymeric fibers or high-volume synthetic fibers) may allow reduction or elimination of joints. A 4-inch concrete topping with 7.5 pounds/cubic yard of Forta Ferro fibers was placed at the Sparkles Roller Rink in Marietta, Georgia with no joints and has experienced no cracks after 3 years in service.

- Placing 0.5% reinforcing steel in the top 2 inches of the slab in both directions can allow you to eliminate joints. That is about a #4 bar at 10 inches on center. This doesn't really eliminate cracks, but results in very fine, more closely spaced cracks.

- A recently introduced product from Australia, the Joint Free Slab, induces narrow cracks on a 1-meter-square grid by positioning crack inducer tubes on the subbase before placing the concrete.

- Post-tensioning the slab in both directions can allow joints to be eliminated by placing the slab in continuous compression. Post-tensioned slabs can also function well with poor subgrades.

- Shrinkage compensating concrete (Type K), with an experienced contractor and designer, can allow a reduction or elimination of joints. Reinforcement (rebar or steel fibers) is placed and the concrete actually expands as it cures, resulting in tensioning of the steel. Eventually, the concrete shrinks back and behaves similar to a post-tensioned slab. Shrinkage compensating concrete has, however, resulted in some problems when improperly used. It requires knowledge of how much expansive cement to use and other factors. One company that has seen a lot of success with this is CTS Cement.

This Australian system induces fine cracks to form on 1-meter squares and eliminates joint cutting. Joint Free Slabs Ltd.

Load Transfer

These plastic sleeves are nailed to a wooden bulkhead to provide a place for a load transfer dowel. Greenstreak.

For most light duty slabs, even driveways, we don't worry too much about transferring loads across joints-or else we count on aggregate interlock to do the job. But across construction joints or contraction joints in slabs that will have heavier loads, we need a way to keep the slabs vertically aligned as the traffic crosses. The problem is that if one side of the joint is deflecting under load, then the wheels will hit a slight rise on the other side of the joint and eventually the edges of the joints will break down. In those cases, when there's a need to transfer loads, here are some things to think about:

Diamond-shaped load plates transfer loads across a construction joint without creating restraint in any direction. Note the activated contraction joint. PNA Construction Technologies.

- Aggregate interlock is created within an activated contraction joint. The broken edge below the joint is irregular enough that the aggregate that projects locks into the other side. If the joints are spaced close together (or the concrete doesn't shrink much), so that they don't open too much, aggregate interlock can be effective. For heavier loads, though, use a mechanical shear-transfer method.

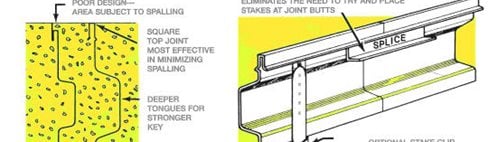

- There are a variety of mechanical load-transfer (or shear-transfer) devices, including dowels (both square and round), diamond-shaped load plates, and keyways.

- Keyways were mentioned in the section on construction joints. They are not normally recommended, although can be effective in construction joints that remain tight.

- Dowels must be aligned properly to be effective. Dowels must be perpendicular to the joint both vertically and horizontally. Misaligned dowels can lead to joint deterioration.

- Dowels must be smooth, with no sharp edges that can catch in the concrete. Rebars do not make good dowels. One half of the dowel, within the concrete on one side or the other, must not be bonded to the concrete to allow the joint to open as the concrete shrinks. Debonding agents or grease are commonly used. Don't apply the grease too thickly.

- The best way to keep dowels properly aligned in a construction joint is to drill holes through the bulkheads, or use a proprietary bulkhead form that aligns the dowels.

- For saw-cut contraction joints, the best method is to use dowel baskets, then come back to cut the joint above the dowels.

- Diamond-shaped load-plates for construction joints are a newer, and very effective, method that allow the slab to shrink in two directions, eliminating all restraint.

- Sizes and spacing for round. square, and rectangular dowels and for diamond-shaped load plates are provided in ACI 302.1R-04, Guide for Concrete Floor and Slab Construction or ACI 360R-06, Design of Slabs on Ground.