- Concrete Homes Home

- Concrete Homes Pictures

- Do Concrete Homes Cost More?

- Optimizing the Energy Efficiency of an ICF Home

- Design Ideas for Concrete Homes

- Related Information

- Hurricane-Proof Homes

- Building Concrete Safe Rooms

- Going Green with Concrete: An Overview of Concrete's Eco-Friendly Benefits

- Tilt-Up Concrete Construction

- Building a Concrete Basement

- Other Resources

- Concrete Home Infographic

- Free Brochures

- Concrete Contractors: Find Concrete Form Products and Suppliers

Section Sponsor

Concrete Homes

Concrete Homes and Home Building

Learn how using concrete and ICFs for concrete home construction can slash heating and cooling costs, improve your comfort and safety, and help preserve the environmentConcrete homes are known for their durability and cost-saving features. In today's construction revolution, there is great demand to build high-performance homes. With ICF construction, homeowners can design a concrete home to look just like a wood-frame house, but they garner many other added benefits by choosing to build with concrete.

If you firmly believe in the adage that your home is your castle, then why not build a true fortress—one that can withstand nearly any assault Mother Nature can dole out without sacrificing the comfort and design flexibility of a traditional home? In fact, many homeowners are doing just that, for reasons ranging from reducing escalating heating and cooling costs to allaying fears of being in the path of a hurricane or tornado. Use this Project Estimator from Fox Blocks to get an idea of how much it will cost to build an ICF home.

WHAT ARE INSULATED CONCRETE FORMS (ICFS)?

While some of these homes use traditional concrete wall systems, such as concrete masonry and concrete cast onsite in removable forms, the most explosive growth is in the use of insulating concrete forms, or ICFs, for building both foundation and above-grade walls. These easy-to-erect, stay-in-place forms are made of high-density plastic foam and filled with fresh concrete and steel reinforcement to create a super-insulated thermal sandwich that's airtight, quiet, and highly resistant to fire and strong winds.

ICF forms are made of various types of foam insulation (see Plastic Foams for Concrete Homes) and come in THREE basic configurations:

Block Systems

A typical block unit is 8" to 16" tall, and 16" to 4' long. They are hollow-core blocks that stack and interlock like Legos.

Panel Systems

These are the largest ICF system and units are 1' to 4' tall and 8' to 12' long.

Plank Systems

These are 8" to 12" tall, and 4' to 8' long.

The main difference between the panel and the plank systems is the assembly method.

Within these basic categories are many different ICF products, differentiated based on the structural configuration they form (such as a flat wall, post-and-beam, or grid system),how the forms attach together, how finishes attach to the wall, thickness, and insulating values.

From a builder's perspective, ICF systems offer numerous advantages over other types of concrete wall construction:

- The foam forms are lightweight and easy to erect; bracing and alignment systems are provided by most manufacturers.

- Because the forms remain in place, contractors can build concrete walls in less time (in as little as a day) for a typical house foundation.

- The insulating forms protect the concrete from temperature extremes, permitting concrete to be placed at below-freezing temperatures and extending the construction season by several months in cold climates.

- The pre-insulated walls eliminate the need for additional insulation and the labor cost of installing it.

- Exterior siding and interior drywall can typically be attached directly to the form faces, with many ICFs incorporating integral attachment systems.

Contact a concrete home contractor by filling out this form.

WHAT DO ICF HOMES LOOK LIKE?

Concrete homes look exactly like "stick built" homes. Insulated Concrete Forms (ICFs) are stacked and braced-then concrete is poured inside the forms. The ICFs have nailing strips that allow the typical interior finishes and exterior treatments such as siding, stucco, stone and brick to be applied. This allows your home to assume any architectural style, from Victorian, to Colonial to ultra-contemporary, and not look like an underground basement. Because of concrete's strength and moldability, you can use ICFs to create any size or style of home imaginable. The foam forms are easy to cut and shape as desired, permitting customized architectural effects difficult to achieve with wood-frame construction, such as curved walls, large openings, long ceiling spans, custom angles and cathedral ceilings.

Find more Concrete Home Design Ideas.

BENEFITS OF LIVING IN A CONCRETE HOUSE

So what's so great about living in a concrete home? What do ICF walls offer that wood-framed walls can't, in terms of comfort, performance, affordability and safety? Here are some of the most compelling benefits, according to statistics from ICFA and PCA.

Lower energy bills

Homeowners can expect a 20 to 25 percent savings in annual heating and cooling costs versus standard stick-built homes, according to a U.S. Department of Housing and Urban Development report. Savings will vary depending on the number and type of windows and doors and the regional climate. The energy savings come from the outstanding insulating values for ICF walls (better thermal resistance than wood framing) and tighter construction.

Learn more: Optimizing the Energy Efficiency of an ICF Home

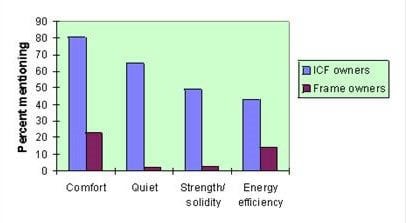

Greater comfort and quiet

Those who live in ICF homes say the absence of cold drafts and unwanted noise are the biggest pluses, even topping the energy-saving benefits. Houses built with ICF walls have more even air temperatures and are far less drafty. The barrier formed by the foam-and-concrete sandwich cuts air infiltration by as much as 75% when compared with a typical frame house. The high thermal mass of the concrete also buffers the home's interior from extreme outdoor temperatures, while the continuous layer of foam insulation minimizes temperature fluctuations inside the home by eliminating the cold spots that can occur in frame walls along the studs or at gaps in the insulation.

ICF walls are equally effective at keeping out loud noises. The greater mass of concrete walls can reduce sound penetrating through a wall by more than 80% when compared to stick-built construction. Although some sound will still penetrate the windows, a concrete home is often two-thirds quieter than a wood-frame home.

Learn more: How to Get Started Building a Concrete Home

Pest proof

ICFs and concrete are an unappealing food source for termites, carpenter ants or rodents that often dine on or reside in wood-framed walls.

Healthier indoor environment

ICF walls contain no organic material, so they won't support the growth of mold, mildew and other potentially harmful microorganisms. They also reduce the infiltration of air that can bring in outside allergens. The polystyrene foam used in many ICF walls is completely nontoxic and free of formaldehyde, asbestos and fiberglass. In tests of the indoor air quality in ICF homes, no harmful emissions were detected. In areas where radon is a concern, ICF foundation walls help to minimize the leakage of radon gas into homes.

Safe haven from high winds

Homeowners and builders in hurricane- and tornado-prone areas are increasingly turning to concrete structural walls to stand up to fierce storms that would otherwise level a wood-frame home. Some ICF manufacturers even offer a discount to families who must rebuild homes destroyed by a devastating storm in regions officially declared federal disaster areas. Tests have shown that ICF walls can withstand flying debris from tornadoes and hurricanes with wind speeds of up to 250 mph. The Federal Emergency Management Agency (FEMA) also recommends ICF construction for building tornado-resistant safe rooms.

Related: Hurricane-Proof Homes: Concrete Fortresses That Stand Strong

Fire resistant

Insurance companies recognize concrete as being safer than any other form of construction when fire threatens a home. In fact, many agencies offer discounts on homeowner's insurance policies. The plastic foams used in ICFs won't add fuel to a fire because they are treated with flame retardants to prevent them from burning. In fire-wall tests, ICF and concrete walls withstood continuous exposure to intense flames and temperatures of up to 2,000 degrees F for as long as 4 hours without structural failure, compared with wood-frame walls that collapsed in an hour or less.

Related: Building Back Better: The Case for Fire-Resistant Concrete Homes

Less repair and maintenance

Because ICF walls use non-biodegradable materials, they are not vulnerable to rot or deterioration as is untreated lumber. The reinforcing steel, which is buried in and protected by the concrete, won't rust or corrode.

Energy efficient mortgages, tax credits and real estate values

Homeowners planning to build or purchase an ICF home may qualify for an Energy Efficient Mortgage (EEM), which allows borrowers to qualify for a larger mortgage as a result of the savings in energy expenses. This would give the owner the ability, for example, to invest more in an ICF home because of the lower monthly heating and cooling bills. For more information, read the U.S. Department of Housing & Urban Development's Energy Efficient Mortgage Program.

In addition, there may be federal tax credits available for building an energy efficient home. Learn more: Federal Tax Credits for Builders of Energy Efficient Homes

Finally, building with ICFs can provide a boost to property values in the following ways:

- Value added for appraisals

- Higher resale values

- MLS green listings (which can help your home stand out)

Read about one homeowner and why he chose to build with concrete.

WHY BUILDING WITH CONCRETE IS GOOD FOR THE ENVIRONMENT

The exploding interest in "green," or environmentally friendly, building products and practices has accelerated the demand for sustainable home construction.

Green building involves designing and building a home — inside and out — to maximize performance and conserve resources. A green home consumes less energy, water and natural resources; creates less waste; and is healthier and more comfortable for the occupants—all qualities that are easily achieved by using concrete and ICFs.

- ICFs optimize energy performance.

- Concrete conserves natural resources, uses recycled materials and is manufactured locally.

- ICFs minimize waste and can be reused as insulation fill on the jobsite or recycled.

- ICFs improve indoor environmental quality by minimizing exposure to mold, mildew and other indoor toxins.

- Concrete builds durable structures.

Using ICFs to build your home can help:

- Improve the HERS (Home Energy Rating System) score

- Achieve Energy Star certification from the federal government

- Earn points towards LEED for Homes certification

Net-Zero Home With Record-Low HERS Index Score

Fox Blocks, an Insulated Concrete Forms (ICF) manufacturer, in partnership with Turning Leaf Custom Homes, a custom home builder whose focus is energy-efficient design and construction in Sanford, FL, has managed to build a Net-Zero home that has an outstanding HERS Index Score of -22.

Learn more: How to Understand Energy Ratings for Your House

See more Eco-Friendly Benefits of Building with Concrete.

WHERE ARE ICF HOMES BEING BUILT?

Although it's almost impossible to spot a concrete home, since the walls are often hiding beneath a traditional façade of brick, stucco or lap siding, chances are good that at least one is located right in your own neighborhood. Many of these houses are custom built, but more builders are beginning to erect entire subdivisions of concrete homes.

According to the Insulating Concrete Form Association (ICFA), ICF homes are being built all across North America, in virtually every U.S. state and Canadian province. In the Northeast, upper Midwest and Canada, ICF homes are allowing homeowners to achieve greater energy efficiency and eliminate cold drafts. Along the Eastern Seaboard and Gulf Coast, ICF homes are valued for their resistance to hurricane-force winds. In the Southwest, ICF homes keep their occupants much cooler in the summer. And on the West Coast, ICF homes provide safety from earthquakes and fires.

In Canada, the growth rate of ICF homes is exceeding even that of the U.S., spurred by government programs to encourage the construction of more energy-efficient housing. According to the Cement Association of Canada, approximately 128,000 ICF homes have been built in North America since the early 1990s, and the growth of ICF use has been steadily increasing at a rate of close to 40% annually.

ICF construction also transcends all affordability levels, from modest starter homes to luxury estates. In many communities, local ready-mix concrete associations and ICF distributors are partnering with Habitat for Humanity to donate both forms and labor to build affordable ICF homes. Fox Blocks, for example, donates its forms or offers special programs available for distributors who wish to participate in Habitat projects in their communities.

Contact a concrete home contractor through the Concrete Network by filling out this form.

Use the Concrete Network to locate ICF suppliers in your area or search the database of the Insulating Concrete Form Association (ICFA) to find distributors and manufacturers of ICFs, experienced ICF contractors, ready-mix producers, designers, and even mortgage lenders that offer reduced interest rates for energy-efficient homes.

Quick Concrete Pumping Tips for Insulating Concrete Forms (ICFS)

CONCRETE HOME PLANS

Plans for a concrete house can be custom drawn by an architect familiar with concrete home construction. Or pre-drawn plans can be purchased online, starting at around $1,000.

If you already have plans for a conventional wood-framed home, don't worry, they can be converted to ICF construction. Speak with your architect, builder or designer about what this entails.

OTHER TYPES OF CONCRETE HOUSES

ICFs are not the only way to build a concrete home, here are the other options.

Precast concrete homes

A precast concrete house is a great choice if you're looking to get in on the tiny house movement. Small concrete homes are ideal for simplicity and efficiency.

Tilt-up concrete homes

Tilt-up construction is widely used for commercial and industrial buildings. However, some homebuilders are starting to use this method for residential houses as well.