- Concrete Step Forms

- How to Form Concrete Steps: See the process, and get tips on pouring steps using liners or foam forms

- Using Step Form Liners: Learn how to take the look of your stairways to a new level using textured step liners.

- Concrete Step Design

- Concrete Step Projects

- Restored Concrete Stairway

- Concrete Skateboard Steps

- Incredible Floating Steps

How to Pour Concrete Steps

A step-by-step overview of forming steps, includes information on form liners and coloring methodsHere are the basic steps for forming concrete stairways, along with tips for using step form liners to give the faces of your steps realistic stone patterns. Also learn various methods for coloring concrete steps and achieving different decorative effects.

Forming and pouring concrete steps

- Sawcut your form lumber and finish corners: Sawcut all but the bottom step forms at a 45-degree angle. This allows for finishing right up to the corner of the step.

- Attach step form liners: If you wish to create stone-like textures on the faces of your concrete steps or a profiled edge, use polyurethane step form liners or foam forms, attaching them to the wood forms with finishing nails.

- Use form supports: Be sure to use wood stakes to brace your forms to prevent them from bowing outward as the concrete is placed.

- Vibrate the edge of your forms: It’s important to vibrate the face of the concrete forms to remove any honeycombs and voids from the concrete surface. Vibrating the forms brings the concrete paste to the surface to fill in any holes. You can tap the wood forms with a hammer or use a palm sander to vibrate the freshly poured concrete.

- Remove forms the day of pour and customize: Remove the step forms and finish the corners of each step the day of the pour, while the concrete is still workable. This will allow you to use concrete chisels to cut hand-tooled joints and texturing skins on step faces and surfaces, if desired.

Concrete Calculator - Find out how much concrete you'll need and get tips for estimating steps

Lightweight Curved Exterior Stairs

The photo at the right was completed using Benchmark Foam insulated concrete forms and geofoam to construct a curved concrete stairway. To reduce the weight and pressure against the building structure, the interlocking ICF forms were used to construct the curved wall while geofoam (encased in poured concrete) was used to build the steps.

You can visit the Benchmark site here: Benchmark Foam Inc

Step Form Liner – RomanSlate Pattern

from $59.00

Step Form Liner – RomanSlate Pattern

from $59.00

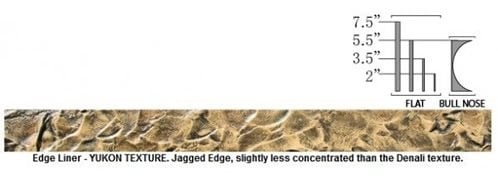

Edge Liners

Liners for limestone, Bullnose,and flat patterns.

Edge Liners

Liners for limestone, Bullnose,and flat patterns.

Brickform Step Liners

Edge Form Liners

Brickform Step Liners

Edge Form Liners

Denali Hammered Edge Liner

from $70.00

Denali Hammered Edge Liner

from $70.00

Butterfield Edge Form Liners

for Steps, Fire Pits, Walls, Wall Caps, Counters & more

Butterfield Edge Form Liners

for Steps, Fire Pits, Walls, Wall Caps, Counters & more

Concrete Stamps - River Rock Form Liner

from $108

Concrete Stamps - River Rock Form Liner

from $108

Tips for using step form liners

- For 45-degree corners, cut the liners using a chop saw or miter saw. Most step liners are also flexible enough to permit bending them into a very tight corner, leaving a rounded corner that is becoming very popular.

- If you have two identical liners, one can be rotated upside down from the opposing liner to avoid pattern duplication.

- If using color hardener with liners, strip the concrete same day it’s poured. Then immediately broadcast the color hardener on the face of the riser so it can react with the moisture in the concrete, and let it set until the next day. Return the next day, wash off the excess hardener, and apply a sealer.

- If you need to use more than one liner for a step edge or you need to cut a liner to fit the actual dimensions of the step, you can eliminate seam marks by rubbing the seam out with your finger and blending it in while the concrete is still wet. If striping the step forms later or if the concrete has thoroughly dried, carefully chisel the seam out, dampen it, and rub it lightly to work up some paste. Then blend the paste in. You can also use a fast-dry caulk to fill the seams in the liners prior to concrete placement.

Coloring optionsIt’s typically recommended that you use integral color when pouring concrete steps to ensure that when the concrete forms are removed, there is color throughout the stair face. You can come back and add more color and highlights after the concrete has cured using an acid stain.

There are several coloring options when using step liners, depending on the final look you want to achieve. “I would say the most popular is using integral color on the step face and a contrasting color hardener on the flat surfaces to produce the most realistic results,” says Harlan Baldridge, Pacific Northwest manager and technical field representative for Brickform. “Most step liners produce enough texture, resulting in shadows that create depth in color. With that said, staining is always an option.”