- Concrete Stain Home

- Get the Look - Stained Floor Pictures

- Color Chart: Concrete stain colors

- Comparison Chart: Compare acid stains, water-based stains and dyes

- Stain Buying Tips: Questions to ask before you buy

- How to Stain Concrete

- Types of Stains and Coloring Options

- Acid-Based Stains

- Water-Based Penetrating Stains

- Concrete Dyes

- Concrete Paint

- Exterior Concrete Stain: Click through images of outdoor stained concrete projects

- Stains and Equipment Product Reviews

- Troubleshooting Concrete Stains

- Common Staining Issues: Tips from expert Chris Sullivan

- Removing Stains from Concrete

Choosing the Right Type of Concrete Stain or Dye for Your Project

Concrete is a very unique substance. It’s strong enough to build buildings, yet absorbent like a giant sponge, allowing you to stain it almost any color you desire. Stains and dyes for concrete come in a variety of different formulations, running the gamut from water-based low-VOC products to harsher chemical-based solutions. All have their advantages and disadvantages, depending on the application and the artistic effects you are striving for. Here’s a broad overview of the common types of concrete stains and dyes, and what I think are the pros and cons of each based on my experience as a decorative concrete artisan. I also share a few tips for achieving the best results with each product.

Acid StainsAcid stain reacts with the surface of the concrete, so the color is permanent, as long as the surface is protected by a sealer. The downside of acid stain is that you are limited to earth-tone color choices. I often dilute acid stains to create a lot of amazing effects, but my color palette is still restricted to earth tones. I find this to be a great stain for exterior concrete surfaces because the color won’t change over time as long as you keep the surface protected.

Tips for using:

- Always remember to neutralize the surface after the stain is done reacting. There is still a chance that ground moisture wicking up through the concrete could cause the stain to start reacting again.

- Be sure to remove any stain residue that might create a barrier for sealer penetration. I recommend using a pressure washer on exterior surfaces and thoroughly mopping interior concrete.

Because the above examples are on exterior concrete that still had a great surface to react, I used acid stains. I prefer acid stain outside because it reacts permanently with the surface and is easy to protect with normal sealers.

Vintage America Acid Stain

Organic, antique patina, deep penetrating reactive stain.

Vintage America Acid Stain

Organic, antique patina, deep penetrating reactive stain.

Acid Stain by Surfkoat

Makes up to 2 gallons. Great for marble look.

Acid Stain by Surfkoat

Makes up to 2 gallons. Great for marble look.

Stain-Crete by Increte

9 standard colors. Useful for old or new concrete.

Stain-Crete by Increte

9 standard colors. Useful for old or new concrete.

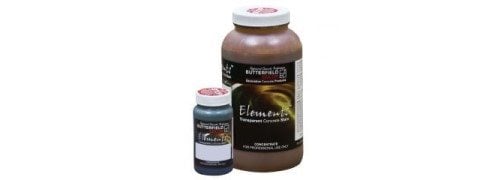

Elements® Transparent Concrete Stain

Water-based, environmentally and user-friendly

Elements® Transparent Concrete Stain

Water-based, environmentally and user-friendly

Concrete Stain + Sealer in One

Waterproof, strengthen, preserve and beautify in one step

Concrete Stain + Sealer in One

Waterproof, strengthen, preserve and beautify in one step

Concrete Acid Stain

BRICKFORM Blush-Tone Acid Stain available in 10 standard colors

Concrete Acid Stain

BRICKFORM Blush-Tone Acid Stain available in 10 standard colors

In-Fluence Water-Based Stain

24 non-reactive colors that transform concrete.

In-Fluence Water-Based Stain

24 non-reactive colors that transform concrete.

Need a contractor? Find companies that specialize in concrete staining near me.

Powdered Acetone DyesMost acetone-based dyes come in powdered form. They are great for interior use, and come in a wide range of color options. But they are not UV stable, so they typically can’t be used outdoors. A big advantage of dyes is their short dry time. Acid stains need to react for hours, while dyes can dry in seconds. (See How Concrete Dyes Work).

Tips for using:

- Since acetone dyes are interior-only products, the profile of the concrete surface becomes extremely important. In order for the dye to bind or absorb into the floor, the pores in the surface must be open. You can do this by grinding the surface.

- If you want to chemically etch the floor surface to open it up, I can tell you from years of experience that muriatic acid will not break down the surface enough to give you as good of a bond for stains and dyes than grinding does.

- Powdered dyes are the only type of dye you can use to color floors that will be polished because they penetrate into the concrete.

Liquid Acetone DyesLiquid dye is not actually a dye but more accurately a very thin, UV-stable solvent-based stain with particles small enough to absorb into the surface. They come in a larger range of color choices than non-UV-stable powdered dyes. I love the color ranges you can achieve in a short amount of time. Like their powered cousins, these dyes dry very quickly.

Tips for using:

- You can’t polish surfaces colored with liquid dye, like you can with powdered dye. Although liquid dye does a great job of penetrating into the concrete, it will still leave a small film on the surface that would be removed during the polishing process.

- I use acetone dyes all the time with very hard topcoatings like urethanes and epoxies. I have no plans for anyone to ever wear through my floors.

For these floors, I used liquid dyes because I needed more color choices. I usually coat them with high grade epoxies and urethanes to protect them from heavy foot traffic.

Water-Based StainsMost water-based stains are more of a paint designed to bond to concrete, and like paint, they come in a broad range of colors. However, they are a surface coating only because the particles tend to be too large to absorb into the concrete. As an artist, I like how water-based stains give you a longer working time than with dyes, which gives you greater control over color.

Tips for using:

- With water-based stains, the concrete surface profile is extremely important. Since these stains are more about bonding and less about absorption, the surface needs to be rougher than with dyes.

- These stains work well in outdoor settings since they are UV stable, but remember to reseal them regularly. Since these stains are like a sheet of plastic bonding to the surface, you need to protect them.

- Only water-based stains and UV-stable acetone dyes have white as a color option. That’s because the actual particle that makes white -- titanium -- is too large to absorb into the concrete.

Water-based stains allow me to layer more colors and have more design details by giving me additional time to work with the colors.

Solvent-Based StainsThese stains are used primarily to tint solvent-based coatings. Depending on the solvent used, they can dry fairly quickly. Indoors, I like to use solvent-based stains with epoxies and urethanes as an easy way to create a solid color that will last, especially for industrial or other high-traffic floors.

Tips for using:

- When using these stains to tint coatings, make sure they are compatible with the chemical-makeup of the coating.

- Use caution when using these stains to tint outdoor coatings. Because the stain will be bonding to the coating rather than the concrete, the color will come off if the coating wears away. I see this happen all the time, and it is very difficult to recoat and correct the color in these spots. Normally I protect outdoor surfaces with solvent-based sealers. It is always best to reseal every 2 to 3 years.

Solvent-based stains were used here because the exterior surfaces were either in too bad a shape for acid stain or I needed lighter color around pools decks to help keep the surface cool on hot sunny days.

Practice Makes PerfectOnly practice will teach you how to choose the best stain or dye for each project and how to use or combine them to achieve the desired look. For each job, I like to use a different mix of stains and coatings to create unique effects. Whenever possible, make samples for each client so they can see the results. For exterior projects, you may need to pour a separate slab to create samples on. On interior floors, you can always test in closets. Years ago when I was first starting out, I would sometimes make samples on floors in rooms to be covered by tile or carpet. Clients like seeing the process. Show them ideas they never imagined possible.

To contact Rick, email him at rick@concretemystique.com, or visit his company’s website at www.concretemystique.com