The challenge

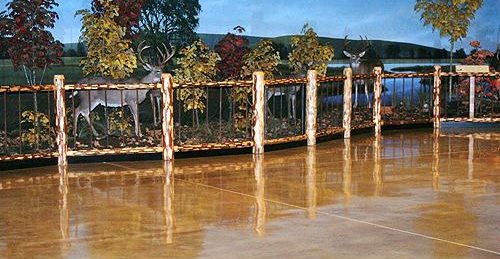

Cabela's Outfitters, a popular retailer for hunting, fishing and outdoor gear, had many concerns about the polished concrete floors installed in their new stores. In some stores, the color wasn't consistent and the shine wasn't lasting very long.

"Since these floors were all new construction, there were many people involved who didn't understand polished concrete right from the very beginning," says Lars Anderson, a consultant with concrete flooring expert Concrete Treatments Inc. "Cabela's had the understanding of how a polished concrete floor should perform when done properly, but had relied heavily on the architectural firm to help see the projects through. Back in 2007, when the work was done, not many people had heard of polished concrete, or understood what it took to get the desired results."

Project goals

The specifications originally written for the polished concrete were vague, so there was no quality control right from the beginning. "We found that steps were being skipped, color samples weren't being verified, there was no prepour meeting, and maintenance was being done all wrong," Anderson explains. Concrete Treatments was brought in to rectify these problems in new Cabela's stores in Hammond, Ind., and Rapid City, S.D. These projects involved over 40,000 square feet of polished concrete.

Secrets to success

-

Concrete Treatments started grinding with a 60/80-grit hybrid resin to cut the floor, and then followed with a sequence of 100-, 200-, 400- and 800-grit resin-bond diamonds, applying densifier to the floor after initial grinding and introducing color at the 400-grit level.

-

The crew performed two passes with each diamond to ensure that all scratches from the previous pass were removed, resulting in a cleaner polish.

-

The dye used to color the concrete was mixed in large batches to ensure color consistency over a large area.

-

To protect the floors from damage by other trades during the grinding and polishing process, the crew worked evenings and overnight, and covered the areas not being worked on with plywood.

Materials and equipment used

Planetary floor grinder and diamond tooling: Concrete Polishing Solutions (CPS)

Floor densifier and topical guard: Armor, from CPS

Concrete dye: AmeriPolish dye in caramel, from American Decorative Concrete

Find polisher and grinder manufacturers

Find concrete dye manufacturers

Project awards

The floor in the Hammond, Ind., store earned an award for excellence in concrete construction (2007) from the Indiana Ready Mixed Concrete Association.

Advice on maintaining polished concrete

In addition to polishing concrete, Concrete Treatments provides education on how to care for polished floors. "Polished concrete is a very durable floor, but it's not bullet-proof. After years of use and lack of proper care, the look of polished floors can begin to diminish," says Anderson.

Concrete Treatments begins by telling each customer how to properly care for their floor. If the customer doesn't want to take on the responsibility of floor maintenance, Concrete Treatments also offers maintenance services for polished concrete. "Although we won't sweep floors every night, we will come back monthly, quarterly, bi-annually or annually to burnish the floors and restore them to their original luster. This will ensure that the floor will always look its best," says Anderson.

Industry trends

Anderson is seeing some positive trends in the polished concrete industry. "As the public becomes more aware of this as a feasible flooring solution, many more projects are being specified," he notes. "Tooling and machine manufacturers have also made leaps and bounds in designing diamond tooling to get nice-looking floors."

On the downside, education about polished concrete is still lacking among contractors, architects and the general public, according to Anderson. "Until recently, there hasn't been a central organization to promote the polished concrete industry," he says. "The Concrete Polishing Association of America (CPAA) was formed exactly for this purpose: to promote high standards, increase awareness, and create a desire for concrete processed to a polished finish," he says.

Contractor

Concrete Treatments Inc.

Albertville, MN 55301