- Concrete Homes Home

- Concrete Homes Pictures

- Do Concrete Homes Cost More?

- Optimizing the Energy Efficiency of an ICF Home

- Design Ideas for Concrete Homes

- Related Information

- Hurricane-Proof Homes

- Building Concrete Safe Rooms

- Going Green with Concrete: An Overview of Concrete's Eco-Friendly Benefits

- Tilt-Up Concrete Construction

- Building a Concrete Basement

- Other Resources

- Concrete Home Infographic

- Free Brochures

- Concrete Contractors: Find Concrete Form Products and Suppliers

Section Sponsor

Concrete Homes

Concrete Home Combines Sustainability with Unique Design

Featuring ICF walls from top to bottom, this canyon-side home was built with energy efficiency and safety in mindDesigning and building a custom home always presents a special set of challenges, including timely construction, managing costs, satisfying local building codes and, most important, pleasing the clients. For the Monahan residence on Canyon Crest Drive in Sisters, Ore., the use of insulating concrete forms (ICFs) for all the home's exterior walls not only passed these tests with flying colors, but also provided a comfortable, quiet, safe and energy-efficient living environment.

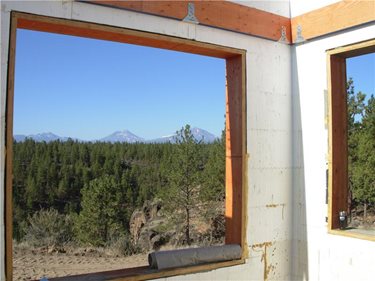

Perched on the rim of a canyon, the 2,750-square-foot two-story home is designed to take full advantage of its dramatic setting. The home blends in beautifully with the surrounding environment and is small in footprint to reduce the impact on the land. Adding to the aesthetic appeal is an attractive acrylic-stucco exterior finish and a metal roof in a warm, weathered copper color. The home is a recipient of a 2008 Insulating Concrete Form Association Excellence Award, presented annually for the most innovative and noteworthy ICF projects in North America.

The homeowners, Linda and Bill Monahan, had already studied the benefits of ICF construction and were sold on the superior sound and thermal insulation properties. But safety was important to them as well. The house is located in a fire-hazard area and is subject to high winds, so ICF walls were more viable than wood. The ICF system used, from Reward Wall Systems, is engineered to stand up to winds as high as 200 mph and exposure to fire for up to 4 hours.

Because of the super-insulated ICF walls, the home has earned certification from Energy Star and Earth Advantage, two programs that promote and recognize energy-efficient home construction. Other energy-saving features of the house include a passive-solar design, with a south orientation and three large south-facing windows, and in-slab radiant heating powered by a high-efficiency propane-fired boiler. Three-foot eaves block out the sun's rays in the summer while permitting light to enter and warm the home in the winter.

In addition to the exterior walls, the main floor slab of the home is concrete as well, placed over under-slab insulation and treated with a decorative stain to eliminate the need for a floor covering. The second floor is I-joist construction, with a gypsum concrete floor underlayment covered by tile.

ICFs make 'perfect sense'The Monahan home was completed in March 2008, with a total construction time of 10 months. Duey Brothers, the general contractor and ICF installer, used the Reward wall system for the entire exterior shell, using wood framing only for the roof and interior walls and joists. The ICF forms, supplied locally by Hooker Creek Companies, feature an open-web design sandwiching a 6-inch core of concrete between two layers of 2 ½-inch-thick insulating EPS foam.

John Nason with Hooker Creek says that even though residential construction in Central Oregon has nearly slowed to a halt in the last two years, there is still activity in the high-end market and a demand for ICF construction. "We are working on three large custom ICF homes going up this summer," he says. "ICFs make perfect sense in our climate; which is hot in the summer and downright freezing in the winter, with two variable seasons in between."

Duey Brothers, a small custom builder that completes only two or three homes a year, says that about 75% of their projects utilize ICFs. "We encourage our clients to use ICFs when they have outside noise concerns and want superior insulation performance," says Trevin Duey. "ICFs also work well with stucco siding applications, which is a growing trend in Central Oregon."

On this project, though, Duey Brothers did not have to convince their clients about the attributes of ICFs. "They came to us with the ICF plans already drawn, and they chose us because of our experience with ICF construction," says Trevin.

The Monahans have lived in the home for more than a year now, and are experiencing firsthand the comfort and energy savings inherent to ICF construction. "We have no shade from trees whatsoever and still manage to keep a cool home on very hot summer days," they say. Not only are they pleased with the outcome of the project, the Monahans also had fun watching the whole building process. "Duey Brothers took great delight in explaining the ICF procedures to us. They frequently encouraged us to come on site and witness the work in progress. This was very exciting and fun for us."

Canyon Crest home construction teamArchitect: Gramlich Design & Planning, Bend, Ore.

General contractor and ICF installer: Duey Brothers, Sisters, Ore.

Engineer: LB Engineering, Bend, Ore.

ICF distributor: Hooker Creek Companies, Bend, Ore.

ICF manufacturer: Reward Wall Systems, Omaha, Neb. (now Fox Blocks)