- Retaining wall home

- Four common types of concrete retaining walls

- How to Install Concrete Retaining Walls

- Retaining Wall Cost

- Decorative Face Options for Retaining Walls

- Vertical concrete overlays

- Form liners for cast-in-place vertical concrete

- iCON Wall Panels

- Related Information:

- Landscape Retaining Walls: Information and design ideas for residential retaining walls from LandscapingNetwork.com

- Board Formed Concrete

How to Build a Concrete Retaining Wall

A step-by-step guide to pouring concrete wallsPrized for their strength and versatility, concrete retaining walls require precise construction methods. With this high level of technicality comes incredible versatility. Poured concrete retaining walls can be colored, textured, accented with embedded objects and much more. When installed properly, concrete offers much more room for customization than any other retaining wall material.

Here are the steps Tom Ralston, owner of Tom Ralston Concrete in Santa Cruz, CA, follows when pouring a retaining wall:

- Meet with clients and determine what components they want and how the space will function.

- Design the walls - determine shape, size and placement.

- Remove existing plants, top soil and other debris that may be in the way of construction, Ralston calls this process grubbing.

- Lay out and dig the footings.

- Build forms.

- Add rebar for reinforcement, Ralston places rebar every 16” on center.

- Pour footings and wall. If the wall exceeds four feet in height, footings should be poured separately.

- Allow concrete to cure.

- Create contraction joints every 4-6 feet. (see below for more information on contraction joints)

- Remove forms and install waterproofing and drainage system.

- Finish the surface of the wall as desired.

- Install patios, steps and other hardscape elements.

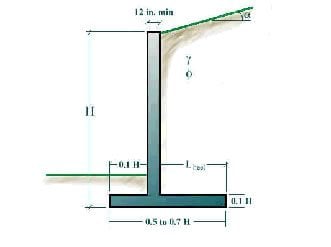

CONCRETE RETAINING WALL PROPORTIONS

Proper proportioning of a retaining wall is just as important to its construction as its structural design. Construction-friendly proportions facilitate proper concrete placement and provide sufficient room for structural reinforcement.

How thick should a concrete retaining wall be?

In addition to basic structural requirements, wall dimensions (generally member thickness) are also affected by the required minimum reinforcement cover. This can add several inches to the wall's thickness dimensions, and can vary depending on the severity of exposure, soil type and reactivity, etc.

In general, the top of the stem of any cast concrete retaining wall should not be less than 12 inches for the proper placement of concrete.

Concrete retaining wall footing size

The depth to the bottom of the base slab should be kept at a minimum of two feet. However, it should always be below the seasonal frost line, and that often is much deeper in northern climates.

The length of the base slab is usually about 50% to 70% of the total height of the wall (bottom of base to top of stem).

For cantilever and counterfort walls, the stem thickness at the base is often about 10% of the total wall height, as is the base slab thickness. Counterfort retaining walls have counterforts spaced at center-to-center distances of about 30% to 70% of the total wall height.

In some cases, a footing key is included to increase resistance to sliding. The footing key is generally an extension of the stem and extends below the bottom of the base.

Cobblestone Form Liners

Give poured walls a decorative look and texture

Cobblestone Form Liners

Give poured walls a decorative look and texture

Vertical Wall Mix

40 lb Bag

Vertical Wall Mix

40 lb Bag

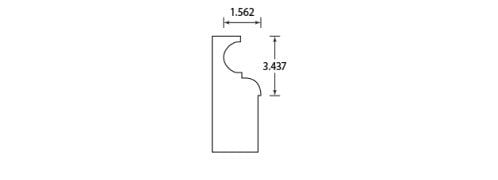

Wall Cap Form

Form and pour concrete caps on block walls

Wall Cap Form

Form and pour concrete caps on block walls

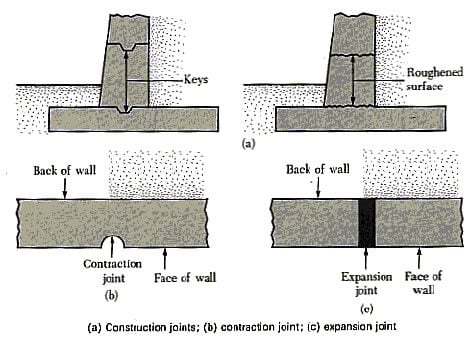

JOINTS IN CONCRETE WALLS

Cast concrete retaining walls may be constructed with any or all of the following joints:

Construction Joints: These are vertical or horizontal joints that are used between two successive pours of concrete. Keys are used to increase the shear resistance at the joint. If keys are not used, the surface of the first pour is cleaned and roughened before the next placement of concrete. Keys are almost always formed in the base to give the stem added sliding resistance. The base is formed first, and the stem constructed afterwards.

Contraction Joints: These are vertical joints or grooves formed or cut into the wall that allows the concrete to shrink without noticeable harm. Contraction joints are usually about 0.25 inches wide and about 1/2 to 3/4 inch deep, and are provided at intervals of not exceeding 30 feet.

Expansion Joints: Vertical expansion joints are incorporated into the wall to account for expansion due to temperature changes. These joints may be filled with flexible joint fillers. Greased steel dowels are often cast horizontally into the wall to tie adjacent sections together. Expansion joints should be located at intervals up to 90 feet.

WHAT IS LATERAL EARTH PRESSURE?

Designing any retaining wall requires knowlegde and understanding of the force generated by the pressure of the backfill against the retaining wall, called lateral earth pressure. To determine the lateral earth pressure, several soil parameters must be known in order for a qualified engineer to assess a particular wall design and its overall stability. These basic soil parameters include:

- Soil unit weight

- Angle of internal friction (for sands)

- Cohesion and plasticity indices (for clays)

- The water table location

Once the lateral earth pressures are known, the wall is checked for stability. This includes checks for wall overturning, base sliding, and soil-bearing capacity failures. After the wall is sized, each wall member is checked for adequate strength and steel reinforcing is determined.

One of the most common and telling failures of retaining walls is the inevitable tilting, cracking and bowing of brick, timber and concrete block retaining walls built by homeowners, well-meaning builders, and landscapers. These "problems" truly are failures, since the wall has not performed the task it was built to do, and that is to hold back the soil.

The failures also clearly demonstrate the lack of knowledge or design that is required by a successful retaining wall design. By understanding how a wall works, and how it can fail, it is possible to engineer a retaining structure that will meet all foreseen environmental, structural and construction demands.

BACKFILL DRAINAGE OF RETAINING WALLS

One area that can be commonly overlooked, or at least underestimated, is the necessity to drain the backfill of rainwater and/or groundwater. Hydrostatic pressure can cause or induce retaining wall failure, or at least damage.

Drainage of water as a result of rainfall or other wet conditions is very important to the stability of a retaining wall. Without proper drainage, the backfill can become saturated, which has the dual impact of increasing the pressure on the wall and lessening the resistance of the backfill material to sliding. Granular backfill material offers the benefits of good drainage, easy compaction, and increased sliding resistance.

Drainage systems usually utilize weepholes and drainage lines.

Weepholes actually penetrate the retaining wall and drain the area immediately behind the wall. Weepholes should have a minimum diameter so as to permit free drainage. For large walls, 4 inch weepholes are common. Adequate spacing between weepholes allows uniform drainage from behind the wall. Weepholes should always have some kind of filter material between the wall and the backfill to prevent fines migration, weephole clogging, and loss of backfill and caving.

Drainage lines are often perforated and wrapped in geotextile or buried in a granular filter bed, and serve to carry water to the weepholes from areas deeper within the backfill.