- Staining Concrete

- Stamped Concrete

- Concrete Overlays

- Concrete Resurfacing

- Concrete Polishing

- Concrete Dyes

- Colored Concrete

- Indoor Concrete

- Concrete Floors

- Concrete Countertops

- Garage Floor Coatings

- Furniture, Sinks, Fire Bowls

- Basement Floors

- Outdoor Concrete

- Concrete Patios

- Concrete Driveways

- Concrete Pool Decks

- Outdoor Kitchens & Counters

- Outdoor Fireplace

- Concrete Walkways

- Concrete Pavers

- Concrete Walls

- Repair & Maintenance

- Foundation Repair

- Concrete Crack Repair

- Concrete Sealers

- Building with Concrete

- Concrete Homes

- Concrete Basements

- Decorative Concrete

- Fire Resistant

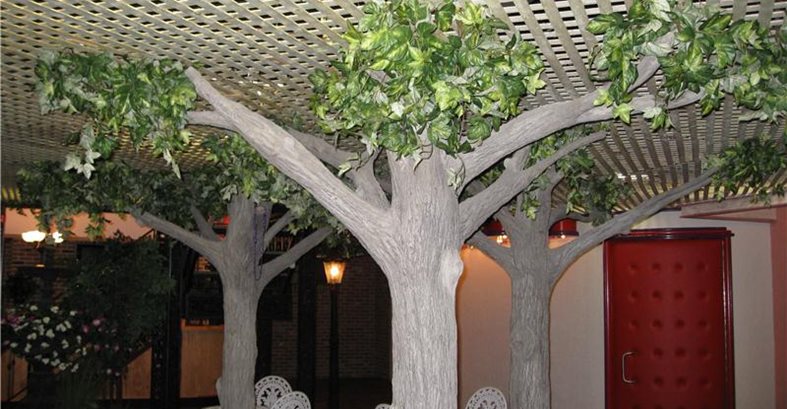

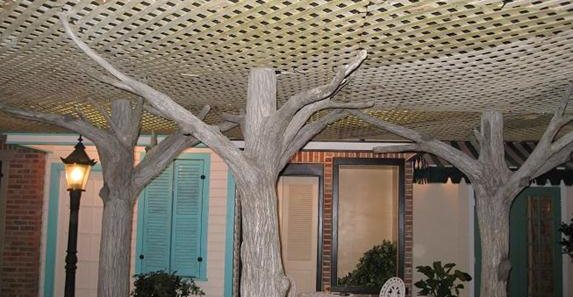

Concrete Trees Grow In a New Orleans-Themed Basement

Support poles encased in concrete are transformed into life-like trees, with bark, branches and allThe challengeThe homeowners, who had moved to Pennsylvania from New Orleans, wanted to recreate the atmosphere of the Big Easy in their basement. "They wanted it to look like the streets of New Orleans, with wrought-iron steps leading into shops that have only the façade of the building built into the walls, and street lights, patios with tables and chairs, benches, and a park where you can sit. The homeowners were concerned about how they were going to cover the support poles, so this is where I came in," says Scott Miller of Millercrete, Sewel, N.J.

The decorative concrete solutionThe solution Miller came up with was to encase the poles with faux-concrete trees, created using a vertical concrete mix applied to Styrofoam. "Many branches were necessary to make the trees look real, so we wrapped the poles with wire lathe and tied the wire to hold the branches and trees in place," Miller explains. A hot knife was used to cut and shape the Styrofoam base, and small blocks of foam were attached to bump out knots in the trees.

Given only five days to complete the trees, so they would be done in time for a Thanksgiving party the homeowners were hosting, Miller's crew needed to work around the clock. "On the first day, we wrapped the Styrofoam around the poles, then glued and wired it up. We banged the wire lathe with a hammer to shape the bottoms and other spots. On the third day, we worked straight through the night and into the next day to finish applying the concrete mix. We didn't finish on the fourth day until 11 at night, leaving only one day for staining, sealing, and drying of the concrete," says Miller.

Secrets to success

-

To ensure good adherence of the vertical concrete mix, Miller brushed on a bonding agent first and then applied the concrete by trowel for the main trunk and by hand for the branches. Another coat of bonding agent was applied before application of a second coat of concrete.

-

The realistic wood-grain texture of the trees was created with bark-patterned stamping mats. To ensure a clean release and to keep the mats from sticking to the fresh concrete, Miller used a bubblegum-type liquid release agent.

-

On the final day, Miller colored the trees with a mix of dye and water-based sealer. "For most of the trees I do, I blend a little brown dye with a water-based sealer, and then I spray it on," he explains. "After waiting a bit, I then rub 50% of the color off to give it more of a gray-brown tone. When the first color is dry, I mix up charcoal dye and water-based sealer. The same process is used to apply it, but then we rub almost all of it off, leaving the dark dye in the crevices of the textured bark." After all the coloring was done, Miller sprayed on two coats of clear water-based sealer as a final finish.

Other applications for concrete trees

Although Miller's company also installs decorative concrete patios, driveways, sidewalks and pool decks, he has established a niche with his faux concrete trees, stumps and boulders,

"I make stumps the same way I make the trees, but they are free-standing. I have given them away to a few of my customers who have shown an interest in them. They work well to cover the electric boxes at the back of pools, to cover well heads, or just to use for towel racks around pools." Miler's trees can also double as beam supports. "I have a friend who bought a local bar, and he wanted some of my trees in his bar. So we put in vertical beams and supported them with trees made out of the Flex-C-Ment, along with concrete countertops. The trees still look great, and it's been five years since I did that work."

Materials usedVertical concrete mix: Flex-C-Ment, from Flex-C-Ment Products, Picayune, Miss.

Bark-patterned mats:Concrete Texturing Tool & Supply, Throop, Pa.

ContractorsConcrete work: Millercrete, Sewel, N.J.

Building contractor: Frank Sedar

Get more basement floor design ideas