- Staining Concrete

- Stamped Concrete

- Concrete Overlays

- Concrete Resurfacing

- Concrete Polishing

- Concrete Dyes

- Colored Concrete

- Indoor Concrete

- Concrete Floors

- Concrete Countertops

- Garage Floor Coatings

- Furniture, Sinks, Fire Bowls

- Basement Floors

- Outdoor Concrete

- Concrete Patios

- Concrete Driveways

- Concrete Pool Decks

- Outdoor Kitchens & Counters

- Outdoor Fireplace

- Concrete Walkways

- Concrete Pavers

- Concrete Walls

- Repair & Maintenance

- Foundation Repair

- Concrete Crack Repair

- Concrete Sealers

- Building with Concrete

- Concrete Homes

- Concrete Basements

- Decorative Concrete

- Fire Resistant

The Sludge Buster

A new solution for handling and recycling waste water in concrete countertop shopsSubmitted by Concrete Countertop Institute

For concrete countertop fabricators, waste water disposal is a hassle that eats up their time and money, and can be unfriendly on the environment. The Concrete Countertop Institute announced a new solution for handling and recycling waste water. Its new product, called the Sludge Buster, provides a simple, inexpensive and compact way to collect, treat and recycle waste water produced from wet grinding and cleaning tools and equipment.

Jeff Girard, president of The Concrete Countertop Institute, explains, "The Sludge Buster is an elegant solution to a problem that plagues every concrete countertop fabricator. Until the Sludge Buster, the only feasible solution to the waste water problem was to collect water in large settling pits or barrels that have to sit for days to months to allow aggregate, sand and large fines to settle out. But filtering is not the same as treating. The remaining water is very alkaline and caustic, similar to drain cleaner, and contains dissolved heavy metals and toxic chemicals. The fabricator is left with large volumes of sediment that must be transported to a dump and water that is unsafe, and in many states illegal, to dump down the drain or outdoors."

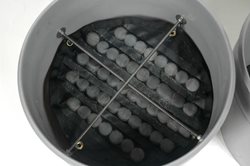

The Sludge Buster consists of a three-stage barrel that weighs 34 pounds and has a diameter of 23 inches. The fabricator uses a shop vac or other means to collect waste water in the barrel. Within minutes, the Sludge Buster filters out and separates aggregate, sand and fines, and chemically treats the water. Treatment by a special filter pod removes remaining sediment, reduces turbidity, and reduces the pH to meet EPA standards for construction water discharge. The resulting water can be captured for reuse or disposed of down the drain or outdoors. The resulting clean aggregate and sand can be reused, and the small volume of treated fines can be disposed of responsibly.

Many fabricators have a designated area for sludge to collect, which fills up and must be shoveled and disposed of. The Sludge Buster eliminates the need for drainage pits and waste water collection areas. The Sludge Buster is also portable, providing easy access for disposing waste water on cast-in-place projects.

"This system greatly increases the ability to recycle water, aggregate and sand, and greatly reduces the amount of time and money the fabricator has to spend dealing with waste, all in a simple, compact and inexpensive form. Finally, there is an easy and responsible way to deal with sludge."

The Sludge Buster system costs $548, and may be ordered on The Concrete Countertop Institute website at www.concretecountertopinstitute.com/sludge. Refills of the filter pod, which lasts for up to 200 gallons of waste water, are also available on the website, as well as an optional 24-foot extension hose.