- Staining Concrete

- Stamped Concrete

- Concrete Overlays

- Concrete Resurfacing

- Concrete Polishing

- Concrete Dyes

- Colored Concrete

- Indoor Concrete

- Concrete Floors

- Concrete Countertops

- Garage Floor Coatings

- Furniture, Sinks, Fire Bowls

- Basement Floors

- Outdoor Concrete

- Concrete Patios

- Concrete Driveways

- Concrete Pool Decks

- Outdoor Kitchens & Counters

- Outdoor Fireplace

- Concrete Walkways

- Concrete Pavers

- Concrete Walls

- Repair & Maintenance

- Foundation Repair

- Concrete Crack Repair

- Concrete Sealers

- Building with Concrete

- Concrete Homes

- Concrete Basements

- Decorative Concrete

- Fire Resistant

An International Tour of Exposed Aggregate Finishes

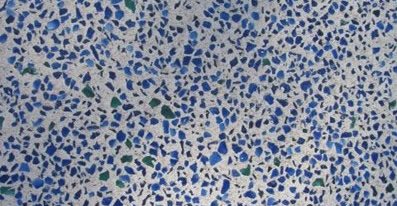

See these amazing examples of exposed-aggregate concrete from around the worldI'm not sure when or where exposed-aggregate concrete originated, but it has been around for ages. I wouldn't be surprised to learn that some Roman concrete contractor installed the first exposed-aggregate sidewalk, leading to the Coliseum.

Exposed concrete finishes are one of the most-used decorative finishes around the world. Taking local aggregates with vibrant color and using them in a concrete mix is one of the best ways to achieve a beautiful, lasting decorative finish. Many places around the world have a large assortment of aggregates to choose from at a reasonable price. The Philippines is one of these areas. I had a chance to visit an aggregate and pebble distributor in Bulacan, about an hour from Manila. They were set up with every color of aggregate you can imagine. All the aggregates were graded and ready for use.

The color and durability that can be achieved using decorative sand, aggregates and glass in a concrete slab is unmatched. I love that the market is using traditional exposed-aggregate finishes, but with a new-age twist. Glass mirror and decorative aggregates from around the world are being used to create extremely wear-resistant surfaces that look like nothing else on the market. I am seeing beautiful sand-wash finishes that increase the long-term durability of the slab by removing the weak cement paste. There are huge benefits to these systems when installed correctly. By removal of "the wear cap" of cement, the strongest part of the concrete mix (the aggregate or sand) becomes the walking surface. I have seen projects around the world that have been in use for generations, yet still look like they were installed yesterday.

Like most things in the world, there are cycles and trends. Decorative concrete is the same way. I believe we are seeing a shift in the market, especially internationally. Exposed finishes are gaining strength in architectural circles due to their durability and amazing looks. Here are pictures of some decorative exposed finishes I have found around the world. Who knows how long these slabs have been installed, but one thing for sure is that exposed aggregate is here to stay. As contractors continue to experiment with decorative pebbles, glass, and even glow-in-the-dark synthetic aggregates, there is sure to be a bright future for exposed concrete work.