- What is Concrete Made of

- Pouring Concrete

- Concrete Mix Designs

- Aggregates in Ready-Mix Concrete

- Building Concrete Slabs

- Concrete Testing

- Seasonal Pouring Tips

- Repairing Concrete

- Concrete Repair

- Fixing Decorative Concrete

- How-To Videos

- Concrete Videos

- Applications

- Staining Concrete

- Stamped Concrete

- Concrete Countertops

- Concrete Patios

- Concrete Floors

- Commercial Concrete

Concrete Parking Lots

Learn the advantages of concrete parking lots and the special requirements for design and constructionConcrete parking lots are a potentially lucrative market for concrete contractors and make good economic sense for building owners. Today, about 90% of parking lots are paved with asphalt, but improved equipment and rising prices of asphalt have made concrete more competitive. When you throw in the other advantages of concrete, especially the long-term costs, it is, as contractor Len Swederski says, a no-brainer.

A concrete parking lot is really nothing more than an exterior slab on ground (or slab on grade). Perhaps what defines it as a parking lot, and what makes it a little different to design and build, is the sloped surface for drainage, the ability to handle heavy vehicular loads, and severe environmental exposure.

WHY CONCRETE PARKING LOTS MAKE SENSE

Let's look at how to design and build concrete parking lots and also why concrete parking lots are preferable to asphalt. Contractors need to understand the advantages of concrete parking lots in order to clearly justify them to their customers.

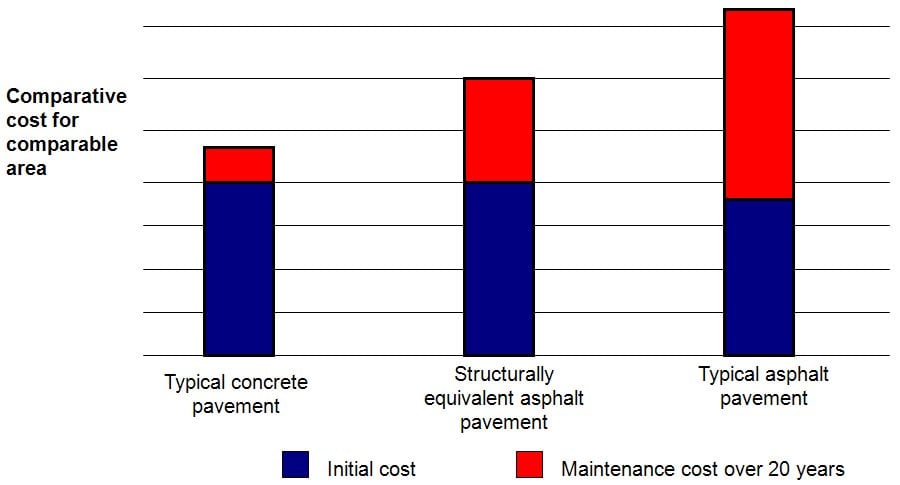

While the initial cost of installing asphalt is still less than that of concrete, rising asphalt prices have narrowed the gap some. For years, contractors have emphasized concrete’s lower life-cycle costs based on its longer life span and lower maintenance needs. When these factors are considered, concrete wins the race.

Even structurally equivalent asphalt pavement that is designed to have the same load-carrying capacity as concrete and has an initial cost that is comparable to concrete, will still need to be resealed and resurfaced. Over its lifetime, the most expensive pavement is a typical asphalt pavement which is cheaper to build initially, but is under-designed in load-carrying capacity and ends up with high maintenance costs.

Here are a few of the reasons why a building owner should pave his parking lots with concrete:

- Asphalt is similar to concrete except that it uses liquid asphalt as the binder rather than portland cement. Liquid asphalt is a residue left over from refining crude oil to make gasoline. Improvements in refining techniques have led to asphalt shortages.

- Maintenance costs for concrete are nearly zero—only some joint sealing and annual cleaning. Asphalt parking lots need to be coated with liquid asphalt every few years and be completely resurfaced every 10 years or less, causing interruptions of use of the parking lot for the business.

- Concrete surfaces are much lighter colored, meaning that lighting costs can be reduced—you can eliminate 3 of 10 light fixtures and still have the same level of lighting, according to Vance Pool of the National Ready Mixed Concrete Association. This creates a safer parking lot and also reduces energy costs.

- The lighter color also results in a lower temperature for the parking area during the summer, reducing the heat-island effect and lowering cooling costs for adjacent buildings. According to Pool, ambient air temperatures above a concrete parking lot can be as much as 10° cooler than an asphalt lot.

- Concrete pavements can carry heavy loads without rutting or developing potholes. With concrete's rigidity and high strength it only takes 5-inch-thick pavement to provide the same load-carrying capacity as 8 inches of asphalt.

- Concrete parking lots can be colored and textured to meet the owner's desires.

- Concrete parking lots are green—runoff is low toxicity and cooler than from asphalt surfaces. Also, concrete can contain recycled materials such as fly ash, slag, or recycled concrete aggregate, which can yield LEED credits.

- Comparing the combined cost of initial installation and 20-year maintenance costs, concrete is considerably less expensive. Maintenance for an asphalt lot can be as much as 80% of the initial construction cost; and on one Florida project, asphalt was shown to be twice the cost of a concrete lot over 20 years.

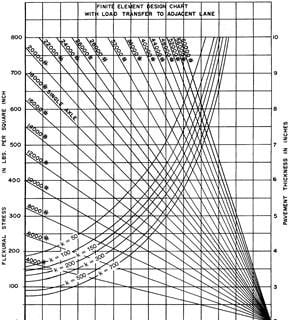

The pavement designer can use this nomograph and an iterative technique to come up with the pavement thickness based on the subbase strength and the anticipated loads. ACI 330R-01

DESIGN

When comparing parking lots to other concrete applications, they are obviously subjected to higher loads than floors. The loads are mostly static (or low speed), so flatness and smoothness are not as critical as for streets and highways. With a parking lot, a good subbase, proper thickness, drainage, and traction are more important.

Parking lots are usually designed in accordance with ACI 330R-08, Guide for Design & Construction of Concrete Parking Lots, although the design method shown in that document is based on the Portland Cement Association's thickness design method. The nomograph shown here will yield a design thickness knowing the subgrade reaction (k), the expected loads (how heavy the vehicles will be), and the number of load repetitions expected over the 20-year pavement life.

Here are a few things to understand about design of concrete parking lots:

- An important consideration is that there's more to the parking lot than just pavement. Parking lots include slabs, joints, curbs, light poles, and drainage facilities — and all of these need to work together.

- Parking lots are typically placed directly on the existing soil rather than on a compressed subgrade. The important thing is to get the compaction of the subgrade uniform so that some areas don't sink and crack the pavement. Find more information on subbases and subgrades.

- For cars and light trucks, a 4-inch pavement is generally acceptable. For bigger delivery trucks, the pavement will need to be 5 or 6 inches thick. This is dependent on the subgrade, the total number of load repetitions, and the weight of the vehicles.

- Parking lots generally drain simply to the edge of the pavement or into gutters. Sometimes drains are located within the paving area. In either case, pavements should slope a minimum of 1% (1/8 inch/foot); 2% (1/4 inch/foot) is better; 6% is the maximum slope in areas where cars park. Slope of entrances to the parking lot should not exceed 8% to prevent cars from dragging.

- Jointing in a concrete parking lot is no different than for any slab on grade. See a complete description of joints. Parking lots should be isolated from any buildings, drains, or light post foundations by installing isolation joints. Contraction joints should be continuous (not staggered), in square panels, and spaced at the intervals shown in the table below.

This pavement drains to a low trough that discharges to a drainage structure at the edge.

A well-thought-out jointing pattern will prevent random cracks. A&E Concrete

| Spacing of contraction joints according to ACI 330 | |

|---|---|

| Pavement thickness, in. | Maximum distance between joints, ft. |

| 4 | 10 |

| 5 | 12.5 |

| 6 | 15 |

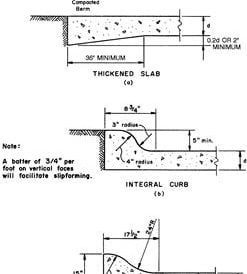

Parking lots are thickened at the edges, either by excavating the subbase or with a curb, to support the loads. ACI 330R-01

- Reinforcement is generally not necessary in a concrete parking lot. If, for any reason, the contraction joints are spaced farther than recommended in the table, reinforcement might be specified to hold cracks together. Similarly, dowels at joints to transfer the vertical loads between panels are unnecessary unless very heavy loads are anticipated—as for heavy truck traffic.

- The exception to the rule about no dowels or reinforcement is tie bars. To prevent the first section of slab from moving away from the parking lot, the first joint in from the edge of the pavement should be tied to the rest of the pavement with tie bars. Tie bars should be ½ inch in diameter, 24 inches long, and spaced at 30 inches on center.

- The edges of parking lots should be thickened if cars will park close to the edge. Edges can be thickened by using an integral curb or by thickening the bottom (see diagram).

- Parking lots can be given just about any exterior decorative treatment, although large lots would be expensive to stamp or texture. Integral color is a good option and may keep the lot looking a little cleaner.

- Check ACI 330R-08, Appendix D for parking space dimensions and the overall geometry of lots. Also don't forget to include handicap accessible spots according to ADA requirements (more info on ADA requirements)

MATERIALS

When thinking about the conditions a parking lot pavement needs to withstand, imagine a parking lot in Michigan in January, or other areas that are exposed to freezing and thawing, deicing chemicals, and heavy loads. Any of these factors can, and will, destroy concrete that is installed with a mix that isn't properly proportioned.

The primary concern with materials should be durability. Pavement durability relies on a good surface layer, freeze-thaw resistance and overall strength. Generally, in freeze-thaw areas where deicing salts are used, 4000 psi should be the minimum compressive strength for a parking lot. However, the real strength issue is the flexural strength rather than the compressive strength, since pavements need to resist bending and cracking more than crushing. Remember that flexural strength is usually about 15% of the compressive strength and the overall bending strength of the pavement is directly related to its thickness.

So to get the durable concrete we want for parking lots, there are a few things to remember:

- Air-entrained concrete is critical for keeping the surface in good shape. Freeze-thaw cycles, especially with deicing salts, will spall the surface of non-air-entrained concrete within a year. Make sure you get the air content noted in the table below.

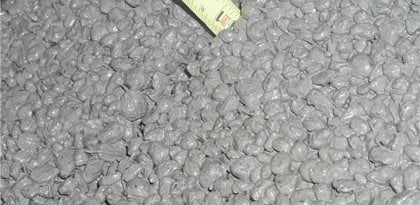

- As with any slab, you'll get less shrinkage (and therefore less cracking) with larger top size aggregate, however, keep it less than 1/3 the thickness of the slab. Well-graded mixes are more workable and also shrink less (and therefore crack and curl less).

- If there is sulfate in the soil, use sulfate-resistant cement--Type II or Type V. Pozzolans (fly ash, slag) or blended cements can also help to mitigate the effects of sulfate.

- Concrete slump should be 4 inches for screeded applications or 1 inch for slipforming.

| Air content to get durable concrete | ||

|---|---|---|

| Total air content, %* | ||

| Maximum aggregate size, in. | Severe Exposure | Moderate Exposure |

| 3/8 | 7.5 | 6 |

| 1/2 | 7 | 5.5 |

| 3/4 | 6 | 5 |

| 1 | 6 | 4.5 |

| 1 1/2 | 5.5 | 4.5 |

| 2 | 5 | 4 |

* This is total air, including both entrained air and entrapped air; tolerance is ±1.5%

ALTERNATIVE MATERIALS AND TECHNIQUES

Concrete parking lots aren't just standard concrete anymore. Here are a few innovative alternatives:

Pervious

Pervious Ultrathin whitetopping

Ultrathin whitetopping Roller-compacted concrete

Roller-compacted concretePervious concrete:

Concrete that drains is an environmentally friendly paving alternative that allows storm water to drain through rather than run off. Get more information on pervious parking lots.

Whitetopping:

Placing a thin layer of concrete over a deteriorated asphalt pavement is only fair, since the asphalt guys are always putting asphalt on top of concrete. This has been done very successfully, typically called ultrathin whitetopping (or UTW). A 3- to 4-inch-thick layer is placed over a milled asphalt surface. Joints are cut on a 3- to 4-foot grid.

Roller compacted concrete

RCC is a great option for heavy duty pavements, such as truck parking lots, container shipping areas, and military vehicle storage. For RCC a zero-slump concrete is placed with dump trucks and rolled with heavy vibrating steel rollers. These road surfaces are only for low-speed traffic and base courses. Learn more about roller compacted concrete.

CONSTRUCTION

As with any slab, there are several ways to construct concrete parking lots. The simplest but least precise method is to simply wet screed the concrete to the desired thickness. Setting side forms and using hand screeds, truss screeds, or other vibrating screeds is another option, and probably the most common. Slipforming is fast and produces very high-quality pavement, although the equipment is expensive and positioning the equipment is difficult except for on very large lots. Another option is to use a Laser Screed with a 3-D attachment that can place concrete precisely and rapidly.

The 3-D Laser Screed can profile concrete pavement to precise slope requirements. Somero Enterprises

The 3-D Laser Screed can profile concrete pavement to precise slope requirements. Somero Enterprises

Broom finished thin overlays add skid resistance and upgrade a deteriorating concrete surface. Concrete Solutions in San Diego, CA.

Here are some tips for parking lot construction:

- Be sure to compact the subbase to get a smooth surface and uniform density. The subgrade should be within plus ¼-inch or minus ½-inch of specified grade. Since parking lot pavements tend to be thin, high spots can lead to thin sections that can fail. Thick sections can cause problems with cracking.

- Compact the backfill for any excavations under the parking lot in 6-inch lifts. Controlled low-strength material (flowable fill) is a good option for this.

- Dampen the subgrade prior to concrete placement in hot and/or windy conditions.

- Finishing of parking lot slabs is typically just screeding, bullfloating, and brooming to get a slip-resistant surface. Find more info on slip-resistance. Troweling air-entrained concrete often leads to delamination of the surface layer and surfaces that would be dangerously slippery when wet.

- The 3-D Laser Screed is a great way to place concrete parking lots if you have a screed and want to get the most use out of it. Using a robotic Geodimeter, the screed can adjust the slope of the surface to any profile desired. The only problem with this approach is that it is so fast it is difficult for the crew to keep up.

- Curing is essential to get a good strong surface. Cure the slab with a spray-on curing compound. You could fog-cure, but that's probably more effort than it's worth for most parking lots. Find more info on curing concrete.

- Joints should be sawed as soon as possible without raveling the concrete-from 4 to 12 hours with conventional saws and 1 to 4 hours with early entry saws. If there are any re-entrant corners, start your saw cuts near the corners first to prevent diagonal cracks. Find more info on preventing cracks.

- A good idea for a successful project is to hold a pre-placement conference with the designer, the owner, the concrete producer, the general contractor, and the concrete contractor. Florida Concrete & Products Association has published an excellent checklist for this conference that is available at www.concreteparkinglots.com under the "downloads" tab. You have to get an access password to retrieve the checklist but it only takes a couple of minutes and is well worth the effort.

MAINTENANCE

When you leave the jobsite, make sure the owner understands what needs to happen to keep the parking lot in good condition. With concrete, it's easy!

Here are some tips:

- Keep traffic off newly poured pavement for at least 3 days in the summer and 7 days in the winter. You want the concrete to have about 3000 psi compressive strength before it takes a load. Truck traffic should be kept off even longer. Deicing salts dripped onto concrete that is less than about 30 days old greatly increase the chance of surface spalling. One option here is to seal the surface with linseed oil.

- For most parking lots, don't use a sealer on the surface unless it appears that the concrete is substandard and can't handle freeze-thaw cycles. However, if you want to keep the lot looking really good and prevent staining, sealers will help. Make sure you get a sealer that allows vapor to escape from within the concrete.

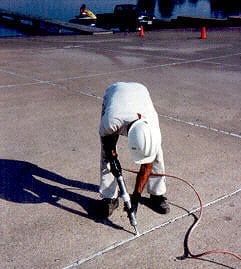

- Joints can be sealed to keep out water and debris, although it's not really necessary if the joints stay pretty tight and the traffic is mostly cars. Heavy trucks can cause pumping of the subbase and result in a loss of support beneath the joint—in that case, joint sealing is necessary. Saw joints to provide a 1/8- to ¼-inch sealant reservoir. Joint sealant can also be applied over isolation joints. Sealants don't last forever and should be checked and replaced as needed.

- Removing stains should be done on a regular basis.

RESOURCES

There's quite a bit of information on the web about concrete parking lots. Here are a few of the best places:

- Portland Cement Association—always one of the first places to look for anything related to concrete; also good information about pervious and roller compacted concrete.

- ConcreteParking.org is a site developed by the National Ready Mixed Concrete Association that promotes concrete parking lots.

- American Concrete Pavement Association—mostly the ACPA focuses on highway pavements, but there's plenty of good info on concrete pavements in general.

- American Concrete Institute—there's not much available free from ACI, but if you want the best information on concrete and concrete parking lots, ACI has it. ACI 330R-08, Guide for the Design and Construction of Concrete Parking Lots is $41 for members or $66.50 for non-members.