- Concrete forms home

- Concrete form liners: Textured form liners for cast-in-place concrete

- Types of insulating concrete forming systems

- Step Forms

- Related Information:

- Concrete Molds: Forms for countertops, sinks and furniture

- Concrete countertop forming videos

Concrete Forms & Supplies

Concrete forms, and decorative liners for adding patterns and texture to concreteConcrete is a unique product that begins its life as a semi-solid, can be manipulated and worked to assume most any shape, and then hardens to assume that shape. This ability to fill voids and assume shapes is what makes concrete the most-used building material on the planet. None of this would be possible without concrete forms.

In simple terms, concrete forms are nothing more than a solid barrier that holds concrete in place or forces concrete to assume a certain shape. However, many newer forming systems serve other purposes as well, such as providing insulation or imparting special decorative effects.

Types of Concrete Forms

Learn about the many types of forms available, from basic wood to specialty systems for decorative concrete.

A square foot of conventional concrete weighs about 150 pounds, and a typical concrete project may require hundreds to thousands of square feet of concrete to be placed at one time. All that weight needs to be held back by concrete forms, which is why most forms are made from rigid wood or metal. In recent years, there have seen some advancements in concrete forms made of plastic, fiber glass and resins, but the cost and strength of these materials are slow to overcome the proven performance of metal and wood.

Concrete forms are often categorized by where and how they are used. The best form for a particular project is often a function of the pour size, the amount of concrete the form needs to retain, and the pressure or weight that will be pushing against the form. For example, the typical concrete forms used for flatwork (such as a patio, driveway, sidewalk or road) range in height from 3 to 12 inches. Because the majority of the weight of the concrete in flatwork applications is spread across a prepared subbase -- which relieves much of the weight pushing against the form -- these forms are most often wood, with metal being used for larger commercial or highway work. In contrast, a concrete form used to construct a bridge pier or high-rise building foundation will hold back hundreds to thousands of square feet of concrete, with the height of the form ranging from 12 inches to 20 feet. Because of the massive amount of weight being exerted against these forms, they are made of high-grade steel and can weigh thousands of pounds.

Wood forms for concrete slabs

The most basic forms for concrete slabs (where the concrete will not exceed 6 inches in height) consist of wooden boards that are screwed or nailed to wood or metal stakes. The stakes are driven into the prepared subbase, and by using leveling devices (such as hand levels, laser levels or string lines), contractors set the forming boards to the proper level or slope. Additional boards are then used to secure the areas where one board butts up against another.

When turns, rounded edges or free-form designs are desired, thinner cross-section boards are used. To keep concrete from sticking to the forms, they are often coated with a low-grade oil, or form-release agent. This also keeps the forms cleaner and allows them to be used multiple times before being discarded.

Insulated Concrete Forms

Fox Blocks is the basis for successful foundations, walls and buildings

Insulated Concrete Forms

Fox Blocks is the basis for successful foundations, walls and buildings

Form Liners

Priced from $42 - $175

Form Liners

Priced from $42 - $175

Brickform Step Liners

& Edge Form Liners

Brickform Step Liners

& Edge Form Liners

Concrete wall forms

In the case of forms used to pour walls or larger structures, such as piers or foundations, pre-manufactured forming systems are often employed. These wall systems, which are typically made from engineered wood with a metal frame or entirely from metal, are designed to attach to each other through a system of pins or latches.

These types of form also use a system of ties to hold reinforcing bars in place inside the form and to secure one section to another when walls are being poured. These forming sections come in a wide range of sizes and shapes, and most manufactures will produce custom sizes for specific projects.

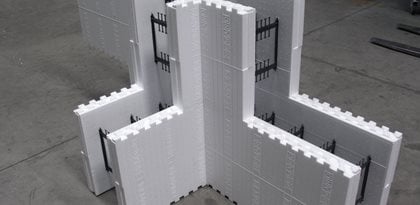

Insulated concrete forms

The trend toward energy-efficient home construction has led to the rapid growth of insulated concrete forms (ICFs). ICF systems are comprised of hollow blocks of insulating material (usually expanded Styrofoam) that fit together similar to children's building blocks. ICF systems are constructed on the foundation slab and remain in place to become the foundation and exterior wall system. A network of metal reinforcing bars is placed inside the block wall structure, and then the walls are filled with a high-slump concrete. The foam and concrete sandwich that is created is extremely energy efficient, and the foam becomes both the interior and exterior construction surface (see How Do ICFS Work?). Using ICFs eliminates the need to remove forms, since the hollow block walls remain in place once filled with concrete.

The cost to construct an ICF home is only slightly higher than for a comparable wood-frame home (about 0.5% to 4% on average), and the added upfront expense is quickly recouped through the savings in monthly heating and cooling costs. (See Do Concrete Homes Cost More?). This type of forming system and construction is more popular in high-energy-use regions where heating and cooling are required for much of the year.

Concrete Contractors: Find Concrete Form Products and Suppliers

Foam Concrete Forms & Decorative Forming Materials

Forms for concrete countertops, furiture and precast concrete products like chairs, tables, planters and benches.

The growth in popularity of concrete countertops, furniture and decorative precast products has led to new and innovative methods of forming (see these videos of concrete countertop forming materials and techniques) and mold making (see Concrete Countertop Molds). These non-traditional methods of forming often involve creating negative spaces or inverted forms, where the concrete piece is actually poured upside down to achieve a desired effect or finish. These forms are often made of materials such as melamine, laminated board or acrylic glass, screw mounted to a large board. Inserts are often attached to the inside of the forms to provide decorative edging or artistic relief.

As more states and municipalities look for ways to beautify concrete construction projects, the use of decorative form liners is growing as well. These plastic sheets with a relief of stone, tile or artistic designs are attached to the inside of the forming system. The concrete assumes the shape and relief of the liner, resulting in a decorative concrete surface. (See Form Liners for Cast-in-Place Concrete.)

Related: Step Forms

How to Form Concrete - Concrete Forming Tips

No matter the type of form or forming system used, the most important factor to achieving good results is how the forms are installed. Forming is often overlooked in concrete construction, but using the right forming system and having it professionally installed can have a significant impact on the concrete's strength and appearance. Proper form installation will result in a uniform and smooth surface, with clean edges and few surface defects.

The growing availability of common forming materials at local hardware and big-box stores have led to a proliferation of do it yourselfers and weekend warriors attempting concrete forming and pouring, especially of concrete countertops. But unless you really know what you're doing, forming is best left to a professional. (See Are Concrete Countertops a DIY Project or Should I Hire a Pro?)

Concrete Forming Product Reviews

Here's an inside look at noteworthy forming systems: