- Concrete Molds Home

- Countertop Molds

- Sink Molds

- Stamp & Texturing Tools

- Edge Molds

- Tips for Making and Using Concrete Molds

- Making molds from rubber

- Related Information:

- Concrete countertop forming videos

Concrete Countertop Forms & Molds

Discover what materials are best for forming concrete countertopsConcrete countertops are formed either top up or top down. The top up nethod is used with cast-in-place counters that are formed and poured directly on top of cabinets. Whereas, the top down method is done in a shop, with the counters delivered and installed much like you would a slab of marble or quartz.

HOW TO FORM CONCRETE COUNTERTOPS IN PLACE

With a top up technique, where the finished countertop surface is troweled, the forms—or molds—do not have to be so perfect, since the surface you are casting against will seldom be seen.

Shop concrete countertop forms & molds

The exception to this is the edges, which often are made with a molded edge form, available from a variety of sources or make your own rubber edge forms. Molded edges can be rough like broken stone or smooth and rounded. Concrete countertop forms are made by a variety of countertop mold manufacturers each offering a unique benefit.

Building concrete countertop forms for cast-in-place applications requires attaching cement backer board to the cabinets and fixing plastic edges to the board. These plastic counter forms are designed to breakaway or snap off when the conuntertop has cured.

A melamine form with wire reinforcement for a concrete island. Reformed Concrete in Quarryville, PA.

PRECAST CONCRETE COUNTERTOP FORMS

Top down casting, on the other hand, means that the countertop surface will be the face that was cast against the mold. For that concrete to look as good as possible, the quality of the mold is essential—it must be perfectly smooth and perfectly sealed. As Fu-Tung Cheng writes in his definitive book Concrete Countertops, "Molds are beautiful in themselves. They are the hidden, backstage actors; they are the chrysalis from which a countertop, transformed from slurry to solid, emerges."

Find local concrete countertop contractors who can help with your project.

Most precast countertop professionals use melamine for concrete forms. Melamine-coated particle board is ideal for GFRC, you don't even need to use release agent. Simply create melamine boxes and seal the inside corners of your mold with silicone.

CONCRETE COUNTERTOP FAUCET KNOCKOUTS & SINK MOLDS

On most countertop projects, you'll need to form knockouts in the countertops for installation of sinks and faucet stems. Since these holes are literally cast in concrete, they must be precise and properly positioned.

Although you can fabricate your own knockout forms for faucets from such materials as PVC pipe, rubber, or foam, you can save time by purchasing ready-made polyurethane or rubber knockouts in a depth to match the countertop thickness. You can also find precision-cut polyurethane templates for sink knockouts. They come in various shapes and sizes to match the dimensions of popular sink brands, such as Elkay, Kohler, and American Standard. However, premade sink-hole templates are normally not available for high-end or custom sinks. In that case, youll need to make your own.

If you're going to be casting a concrete countertop, why not cast a concrete sink as well for a more unified appearance? Fiberglass sink molds for precasting integral vanity, kitchen, and utility sinks can be reused many times.

Slot Drain Ramp Sink Mold

72" with internal reinforcement

Slot Drain Ramp Sink Mold

72" with internal reinforcement

Rectangle Sink Mold

Internally reinforced. Ships in 2 to 3 business days.

Rectangle Sink Mold

Internally reinforced. Ships in 2 to 3 business days.

Release Agent

Prevent concrete from sticking to form liners or texture mats

Release Agent

Prevent concrete from sticking to form liners or texture mats

Countertop Forms

2" thick foam profiles

Countertop Forms

2" thick foam profiles

Countertop Form Liners

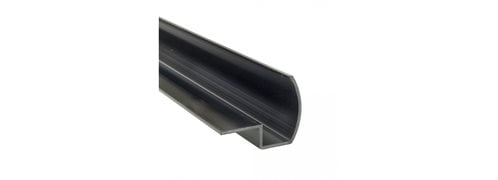

Reusable polyurethane rubber for decorative edges

Countertop Form Liners

Reusable polyurethane rubber for decorative edges

BEST MATERIALS FOR FORMING CONCRETE COUNTERS

Melamine, a plastic coated fiberboard, is the standard material used to mold the countertop surface. Melamine will only last for one or two castings but since most countertops are custom, that's seldom an issue. "If you're a precaster," said countertop pioneer Buddy Rhodes, "you can get several uses out of a sheet of melamine. For one thing, melamine has two sides so you can flip it over and use the other side for a mold. Then in the end you can break it down and use it for packing. We make crates out of it."

"There are a lot of different ways to make molds," said Lane Mangum from the Concrete Countertop Institute. "You can use almost any material to make the shape you want. But there are a couple of other properties that a mold needs: it must be waterproof and, depending on your method, smooth and releasable."

Factors to consider when choosing mold materials include:

- Strength and rigidity. The mold must be able to withstand the pressure of fresh concrete without bowing or distorting.

- Surface texture. Concrete will mirror the surface its cast against, so if a smooth surface requiring minimal hand finishing is desired, use a smooth forming material such as Formica. If you plan to hand trowel the countertop surface (by casting the countertop right side up) or mechanically grind the surface after it hardens, then the texture of the mold wont be as important.

- Workability. Fabricating a mold especially for complex countertop layouts with curves or odd shapes often requires a lot of cutting and manipulation to get it just right. A material that's not prone to splintering or chipping when cut will be easier to work with and reduce waste.

Many materials, including melamine and Plexiglas, will release from the concrete without an added release agent. Other materials, including steel and rubber, require a release agent to be applied prior to pouring. Mangum cautions against using too much release agent on a surface if you hope it to have a finished appearance right out of the form, since release agent can leave a scum on the surface. To "pop a perfect slab" she recommends using something very smooth that will release without a release agent—like Plexiglas or melamine.

With concrete, water content is an important factor in appearance. So if the mold leaks, or absorbs water, the concrete in that area will have a lower water content and therefore a different color. Molds need to be watertight.

MAKING CUSTOM MOLDS

Countertop makers use such materials as Plexiglas, polystyrene foam, urethane rubber (see Making Molds from Rubber), Formica, and even Lexan to make their own molds. "We will use urethane foam and sculpt it to the shape we want it and then jacket it with an epoxy shell," says Mike Karmody, Stone Soup Concrete. "That's what we did on the black island."

On another recent project, a white concrete kitchen countertop, Karmody used Plexiglas laminated onto a plywood mold. They then welded the edges and polished, starting at a 150 grit and finishing with a 1500 grit, then used rubbing compound to get it perfectly smooth. The sink is drafted about 3 or 4 degrees on the sides and the bottom tapers about ¼ inch to the drain point.