- Industrial floors home

- Design & construction of commercial/industrial floors

- Floor flatness and joints

- Concrete Floor Applications

- Staining Concrete Floors

- Painted Concrete Floors

- Stenciling Concrete Floors

- Polishing Concrete Floors

- Self-Leveling Concrete Overlays

- Related Information

- Commercial Concrete: Information about concrete used in retail stores, restaurants, offices, and more

- Retail Floors

- Subgrades and subbases for concrete slabs

- Jointless slabs: How to reduce or eliminate the number of joints

Floor Flatness and Joints

Understanding F-number requirements and jointing for commercial and industrial floorsIn the bad old days, concrete floors were specified without knowing how to actually measure what was being specified. The old flatness requirements of ¼ inch in 10 feet, for example, left so much up to interpretation that it was basically useless. Anyone could measure almost any floor and pass it or fail it depending on how the measurement was applied and what they wanted to happen. Can't you just see a poorly trained testing technician with an old warped 10-foot long 2x4 bending down with a ruler to measure the gap between the straightedge and the floor? Then saying, this floor is no good!

But, today we have F-numbers for flatness and levelness and ACI 302.1R, Guide for Concrete Floor and Slab Construction, that tells us when and how to apply the F number specifications.

Floor Flatness & Levelness

One of the things that distinguishes a high tolerance floor is its F-number requirement. F-numbers were developed in the 1980s to provide a systematic, quantitative way to indicate the flatness and levelness of a concrete floor. The higher the F-number, the flatter or more level the floor. There are actually three F-numbers that are used for concrete floors, depending on whether the floor will have a random traffic pattern or defined traffic aisles.

F-min is measured using a traveling profileograph, which simulates the wheel pattern of a high-mast lift truck. Allflat Consulting

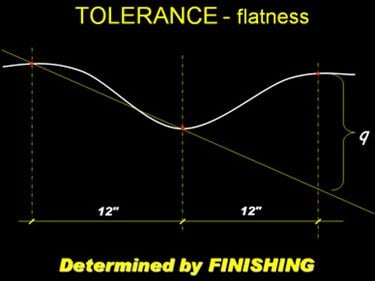

- FF—This number is used to indicate the flatness of a random-traffic floor. FF is measured as the curvature of the floor over a 2-foot interval. Take a grid of 2-foot intervals over the entire floor and put the values through an equation and you get the FF value as an indication of the waviness of the floor. The FF value is primarily a result of how good the finisher was at working the surface to achieve a flat floor. The FF value of a driveway, for example, might be 10 while the FF of a superflat floor could be as high as 125.

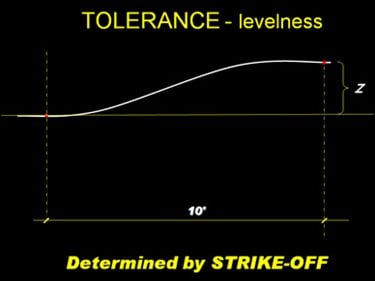

- FL—The second number indicates the levelness of a random-traffic floor and is measured over a 10-foot interval. Again, take all of the 10-foot readings, add them up, and put them through an algorithm (an equation) and you will get the FL value. FLis primarily a result of how good the contractor was at setting the side forms and striking off the concrete and has almost nothing to do with the skills of the finisher.

- F-min—It's important to understand that the F-min value is only applicable to defined-traffic floors, that is, floors with defined aisles along which traffic is to travel. These are typically warehouses that use high-mast lift trucks. There is no direct correlation between FF/FL and F-min. F-min is measured using a profileograph, an instrument that measures the deviation both longitudinally and transversly from perfectly flat.

On a random-traffic floor, FF/FL should be specified both for the entire floor (overall minimum) and for the area within a single bay (local minimum). "The most consistent mistake specifiers make is the failure to specify both overall and minimum-local F-numbers," says Allen Face, Allen Face & Company. "The overall numbers are for the entire floor; the minimum local values apply to each individual square defined by the sawcuts." The minimum-local value is generally specified as 67% of the overall value, which allows a single bay to be slightly less flat and level than the overall floor.

FF and FL are measured using either the Dipstick from Face Construction Technologies or the F-meter from Allen Face & Company. The Dipstick was the original device used to measure these values and is stepped across the floor. The F-meter rolls along a defined line.

DAY1 Finishing Aid

Improve finish, reduce defects, enhance performance

DAY1 Finishing Aid

Improve finish, reduce defects, enhance performance

Industrial Floor Wax

Achieve superior long term wear

Industrial Floor Wax

Achieve superior long term wear

Crack Repair 1 Gallon Kit

from $55.15

Crack Repair 1 Gallon Kit

from $55.15

Polishing Diamonds

Options for hard, medium, and soft concrete.

Polishing Diamonds

Options for hard, medium, and soft concrete.

Encore Finishing Aid

Improve workability and surface quality

Encore Finishing Aid

Improve workability and surface quality

Propane Grinding Machines

Go cordless with the LAVINA elite gtx series

Propane Grinding Machines

Go cordless with the LAVINA elite gtx series

Joints in Commercial Floors

The most common types of joints used in commercial or industrial floors are isolation, contraction, and construction. Contraction joints (saw cuts) are the most important. (Learn more about joints.) Properly spaced contraction joints reduce (or eliminate) cracking and help to minimize curling. In commercial or industrial floors, joints tend to create problems since the edges can get broken off or degraded as heavy fork lift traffic crosses the joints. Minimizing or eliminating these joints is often the best solution. It is the responsibility of the designer to specify the location of these joints-if not defined, prior to construction, the contractor should submit a plan for the layout and placement of these joints.

Joints in commercial or industrial floors are virtually always produced by saw-cuts. Ideally, early-entry saws are frequently used to create these joints. This technology allows the contractor to cut the joint sooner both increasing the speed of the project and preventing random cracks from having a chance to start.

Commercial or industrial floors often have heavier floor loads than residential floors. In those cases, we need to have a way to transfer the shear loads across the joints to prevent joint breakdown. As a heavy vehicle approaches a joint, the slab will deflect slightly. Remember that even concrete bends slightly. As it deflects next to a joint, the top edge will crush against the concrete on the other side of the joint. This will eventually degrade the joints. To prevent this, the two sides of the joint are tied together vertically so that one side can't deflect independently.

For years, designers relied on what's called aggregate interlock-the jagged aggregate on either side of the cracked joint-to transfer shear (vertical) forces across the joint. The trouble is that once the joint has opened even minutely due to shrinkage the aggregate doesn't interlock enough to serve the purpose. That's when shear-transfer devices come in handy. The most effective of these are the diamond-shaped plates that transfer load while allowing the slab to shrink both away from the joint and laterally.

The edges of joints in areas that get heavy traffic need to be supported to prevent them from being broken off on the adjacent slab section. In those cases, we install a rigid joint filler-two-component semi-rigid epoxy resins and polyureas are most common. The joint filler (not a joint sealer, which would be flexible) supports the top corner of the slab and prevents spalling and cracking. Slabs continue to shrink for years, though, so the slab will often pull back from the joint so that fillers may need to be reinstalled.

RELATED:

How to Level a Concrete Floor