- Pouring Concrete in Hot Weather

- Concrete Admixtures for Hot Weather

- Curing Concrete in Hot Weather

- Related Resources

- Pouring Concrete in Cold Weather

- Can You Pour Concrete in the Rain?

- Concrete Mix Design

- Types of Admixtures for Concrete

Section Sponsor

Packaged Admixtures

Seasonal Pouring Tips

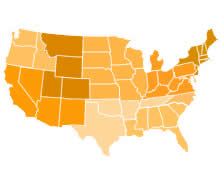

Get guidelines for placing concrete by region and season throughout the U.S.

SELECT A REGION

Concrete Admixtures for Hot Weather

From adding ice to the mix to using concrete retarder, these methods help beat the heatTemperature changes have a big impact on the set time of concrete. "If a stamper doesn't have good knowledge of ways to modify slump and to control set time he's really fighting an uphill battle," says Bannister. In hot weather, concrete with fly ash or slag will set a bit slower. But using admixtures to control set and slump is more common and does not lower the quality of the concrete or change its color.

In the July 2002 issue of Concrete Construction ("Stamping Concrete: Managing Initial Set Times"), Joe Nasvik wrote the definitive guide, advocating a procedure he calls "step retardation" to control set time. This method uses different amounts of retarder added on site to control the set so that you have time to get your stamping done. Bannister, Harris, and Nasvik all recommend Fritz-Pak admixtures for on-site adjustments. Fritz-Pak manufactures retarders, accelerators, and water reducers (superplasticizer) in packets that can be added easily on site.

Find Products: Admixtures

ADJUSTING YOUR MIX FOR HOT WEATHER

Retarding admixtures are a good tool to control concrete in warm weather. Retarder can be added at the plant or on the job site to delay concrete setting time, which can be very quick when the concrete is hot. Retarders give you extra time but they also give the concrete more time to dry out, so curing is critical (learn more about Curing Concrete in Hot Weather).

Retarders come as straight retarders or as water-reducing and retarding admixtures. Mid-range water reducers often also retard the set and both retarders and water reducers can increase the air content of the concrete. Also, if too much retarder is added to concrete used for a slab it can lead to crusting, where the surface sets but the concrete below is still soft. This can really reduce your flatness and even lead to delamination of the surface. To learn more, check out ACI 212.3, Chemical Admixtures for Concrete, and talk with your admixture manufacturer.

In extreme situations, or when concrete has a long trip to the job site, hydration controlling admixtures are available-find Concrete Admixture Suppliers. Ready mix producers can add this material to delay set by up to 5 hours. Kozeliski routinely uses this to ship concrete as far as 200 miles. "On long haul concrete, we limit mixing to 1 revolution per mile, and we leave the plant at about a 5 or 5½ inch slump so we've reduced the friction between the particles and then it doesn't generate heat in transit."

Another way to slow set times is by using fly ash for part of the cementitious material, although this will change the color, so test it in advance and don't alter the percentage between batches. However, with hot concrete, substituting fly ash may not be very effective. "I don't see that fly ash or slag affects the set time if the concrete temperature is above 75 degrees," says Bob Harris from the Decorative Concrete Institute. "At lower temperatures, it does have a dramatic effect but over about 75° or 80° I don't see it."

Mini Delayed Set

Good for step-delay concrete pouring

Mini Delayed Set

Good for step-delay concrete pouring

Rescue-Pak

Contains six of our most effective admixtures

Rescue-Pak

Contains six of our most effective admixtures

Standard Delayed Set

Dry Powdered Admixture

Standard Delayed Set

Dry Powdered Admixture

HOW READY MIX SUPPLIERS KEEP CONCRETE COOL

Use a knowledgeable ready mix producer with whom you have developed a good relationship. The objective is to get concrete that is as cool as possible. Most references don't give a maximum allowable temperature, but any concrete warmer than about 80° could be a problem (learn why heta is a problem: Pouring Concrete in Hot Weather).

Your ready mix producer can do several things to keep the concrete cool, starting with the mix ingredients. Since there's more aggregate than anything else in concrete, aggregate temperature has the greatest effect on concrete temperature. Shading of aggregate piles is ideal, although not always possible. Using cool water is another way to get cool concrete. Ready mix producers in hot climates use chilled water or ice to lower the concrete temperature.

"We have an evaporative cooler that turns on at 2:00 a.m.," says Frank Kozeliski, president of Gallup Sand & Gravel, a ready-mixed concrete producer in Gallup, N.M. "We can get our water temp down to 40° without turning the chiller on. Very seldom in the summer do we have concrete over 80°. We can't really keep our aggregate out of the sun, but a lot of people keep their coarse aggregate wet and if you can get the wind to blow through it the evaporation will lower the concrete temperature 10° with no problem."

HOW TO HANDLE DECORATIVE CONCRETE IN HOT WEATHER

- Fritz Pak admixtures can be added to the mixer truck on site. They are a great way to fine tune your concrete slump and set time. Their hot-weather superplasticizing admixture increases slump by about 7 inches and retards set time by about an hour, although both of these numbers may be lower with hot concrete. Again, be careful of the air content with these admixtures, since it can be increased by up to 2%. Fritz-Pak's delayed set retarders don't increase slump but do effectively delay the set.

- For concrete that is to be stamped, consider using step retardation--adding retarder to the mix after half of the batch or after one-third and two-thirds have been placed. For textured concrete one of the strongest things to do in hot weather is step retardation. "I'll add retarder at least twice," says Brickform's Clark Branum. "Say I have a 9-yard load I'll place the first 3 yards just the way it comes then I'll add 3 or 4 one-yard admixture packets then discharge another 3 yards then throw in one or two retarder packets on the tail. That gives you more time to color and texture and if you're using hardeners or integral colors the retarder won't affect the color either way where water will. You're inducing slump chemically rather than with water."

- Remember that in hot weather, when the effects of a retarder or a superplasticizer wear off, set occurs very quickly. Be ready!

- On hot and dry or windy days, use an evaporation retarder (not a curing compound) that forms a monomolecular film on the surface and will prevent the concrete from drying out, which can lead to plastic shrinkage cracks or crusting. "One thing that I warn guys about," says Branum, "is not to put it under the hardener. Sometimes people spray it on the concrete and trowel it in but that can prohibit bleed water. I recommend that they apply the hardener and float it in and then use it on top of the hardener to keep it moist. You end up working it into the surface a bit but I always install it on top of the hardener." If you are applying a second coat of color hardener, you can use another application of evaporation retarder if the surface seems to be drying out.

- Staining concrete relies on a chemical reaction that happens faster in hot weather. On their web site, L.M. Scofield notes that "Chemicals react faster under heat. Don't stain in 95° to 100° weather; you can ruin a job that way. In a hot climate, stain in the coolest part of the day. Wet the surface down to slow the chemical reaction."

- Most overlay manufacturers recommend that the concrete surface temperature be between 50° and 80° for an overlay installation. Bob Harris, in his book Concrete Overlays & Toppings, notes that "the warmer the air temperature and substrate temperature, the faster the material will set. Installing an overlay in direct sunlight during the hottest part of the day will greatly reduce your working time and jeopardize the quality of the results." Chris Sullivan with QC Products notes that although overlays use polymers, you really need to treat them like regular concrete and target the coolest part of the day for placement. "Some overlay manufacturers offer set retarders," says Sullivan, "so if a contractor is working in hot weather he might want to look into that. Be sure to get the retarder offered or recommended by the manufacturer to make sure it will be compatible."

- In his Q&A post Hot Weather Sealing Basics, Sullivan says that sealers can flash cure if the surface temperature of the concrete or the air temperature is above 90°. "Common sense would dictate that during the hot months, you should avoid sealing during the heat of the day," he says. "Today with the states tightening their VOC requirements, manufacturers have gone to exempt solvents like acetone that tend to flash even faster and we're seeing more problems with sealers blistering and bubbling. Even at 90° you're running a risk."