- Foundation Repair Home

- Foundation Repair Cost: What are the variables?

- Does Insurance Cover Foundation Repair?

- Foundation Cracks

- Methods of Repair

- Piering: Fixing your home's issues

- Slabjacking: What is slabjacking?

- Related Information:

- Concrete repair: Repair methods and troubleshooting basics

- Read more about foundation information on FoundationRepairNetwork.com

- Houston Foundation Issues: Answers to common questions about foundation problems in Houston

Section Sponsor

Foundation Repair Near Me

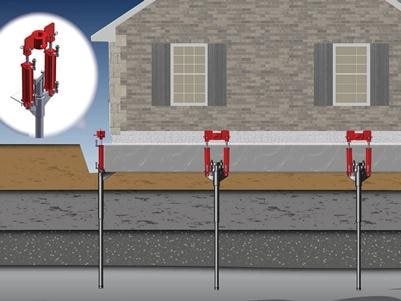

Using Piers to Fix Concrete Foundations

How push & helical piers are used to raise & support a failing foundationPiling or piering is the technique of driving steel pipe pilings to remedy failing building foundations and to correct foundation settlement.

Push piers consist of sections of galvanized or epoxy-coated steel pipe that are driven into the soil with a hydraulic ram.

Helical piers use screw piles with steel shafts. The lead section, with one or more helixes attached, provides the needed bearing capacity. The piers are screwed into the ground with a hydraulic torque motor.

With either system, one or more steel piers are driven to rock or a suitable soil bearing layer and are connected to the foundation through a metal head assembly. Once a suitable bearing stratum is reached, each pile is tested to a force greater then required to support the structure.

Hydraulic jacks attach to the embedded steel piers and are used to raise the foundation back to its original elevation. Once the structure is restored to the desired elevation the piles are affixed (bolted or welded) to wall brackets, locking the new elevation of the structure.

Piers also offer an affordable solution for decks, porches, patios, hot tubs as well as pre-fab buildings.

Advantages of Piers on Concrete FoundationsLearn the benefits of repairing a foundation with piers

The benefits of using piers to repair a foundation are as follows:

- Low cost. Up to ten times less than replacing the building foundation.

- No disruption or loss of use of the dwelling. The repair is performed with the building being used as normal.

- The equipment is portable and can be easily used in tight spaces or carried by hand where access is a problem.

- Remedies both the cause of the settlement (unstable soil) and the consequences (dwelling out of level) in one step.

- No yard destruction

- No heavy equipment

Piering InstallationThe typical steps for using piers to fix a foundation

The steps in the piering process are as follows:

- A 3'x4' excavation is made adjacent to foundation and approximately 10" below the grade beam.

- Soil is scrapped from the footing bottom and the foundation is chipped smooth to ensure proper fit of support bracket.

- Brackets and hydraulics are installed and a guide sleeve is advanced through the support bracket.

- Starter and pier sections are advanced to refusal at an average penetrating power of 50,000 pounds of total driving force.

- The last pier section is cut approximately 5" above the support bracket and a fastening plate is installed on top of the pier column.

- The hydraulics are reconnected and are operated sequentially to raise the structure.

- When the structure has been raised to the desired height the fastening plates and support bracket are permanently attached to the pier column.

- When the structure is secure, depth, pressure and elevation readings are recorded for each pier.

- The excavated soil is replaced and compacted.

- Shrubbery and concrete removed for the pier installation is replaced.

Concrete Push PiersHydraulic foundation repair piers

Push piers are hydraulically driven pier systems consisting of sections of galvanized or epoxy-coated steel pipe. The piers are point bearing and driven with a hydraulic ram through unstable soils to rock or load bearing strata.

Each pier is then individually load tested, and the structure is stabilized with a patented uniform system to insure maximum practical recovery. For the piering system driven by the hydraulic ram, equal bearing strata is assumed to be reached when the jacking load equals the steel pier capacity.

This system, like the Helical Pier system, has been shown to successfully support structures in virtually all soil conditions, and can be used for stabilizing foundations and slabs built on questionable soil, as well as seismic protection, tieback anchoring, deadman anchoring and fixture anchoring. It may be successfully installed even in tight areas.

Helical PiersHow steel piles are used for foundation repair

Helical piers use screw piles with steel shafts. The lead section, with one or more helixes attached, provides the needed bearing capacity. The piers are screwed into the ground with a hydraulic torque motor, and extensions without helixes are added during driving. For the helical pier application, load capacity is determined from the torque measurements obtained from the installation equipment.

This system has been shown to successfully support structures in virtually all soil conditions, and can be used for stabilizing foundations and slabs built on questionable soil, as well as seismic protection, tieback anchoring, deadman anchoring and fixture anchoring. It may be successfully installed even in tight areas.

Related information:

How to design helical piles per the 2009 International Building Code (PDF)

Business opportunity: Ram Jack foundation repair system

Twenty years to build an overnight success: The Ram Jack Story