- Pouring Concrete in Hot Weather

- Concrete Admixtures for Hot Weather

- Curing Concrete in Hot Weather

- Related Resources

- Pouring Concrete in Cold Weather

- Can You Pour Concrete in the Rain?

- Concrete Mix Design

- Types of Admixtures for Concrete

Section Sponsor

Packaged Admixtures

Seasonal Pouring Tips

Get guidelines for placing concrete by region and season throughout the U.S.

SELECT A REGION

Pouring Concrete in Hot Weather

Why is hot weather a problem? What temperature is too hot to pour concrete?Man, it's hot outside! You may be able to handle that heat, but can your concrete work? It can, if you take a few simple steps to help it along. There are many ways to lessen the effects of hot weather on concrete. Once you understand the power of heat and how to control it, your days of uncontrolable set times, shrinkage and cracks will be over.

WHEN TO USE HOT WEATHER CONCRETING METHODS

Leave it to the folks at the American Concrete Institute to provide a long detailed explanation of when you need to resort to hot weather concreting methods. But when you get to the end of that long detailed explanation, you probably still won't know the answer to the question of exactly what's hot. The Committee Report ACI 305R-99, Hot Weather Concreting, says that hot is "any combination of the following conditions that tends to impair the quality of freshly mixed or hardened concrete by accelerating the rate of moisture loss and rate of cement hydration, or otherwise causing detrimental results:

- High ambient temperature

- High concrete temperature

- Low relative humidity

- Wind speed

- Solar radiation

So basically Committee 305 says that we should consider it hot whenever the heat might damage the concrete. Not very helpful. In most cases, figure that you should start thinking about hot weather techniques any time the air temperature is over about 85°, although even 80° with sun and a dry wind could be considered hot. For the concrete temperature, anything above 80° requires some extra precautions.

Find Products: Admixtures

THE IMPORTANCE OF CONCRETE TEMPERATURE

Concrete sets as the cement hydrates. Hydration is an exothermic reaction, meaning it generates heat, and that reaction goes faster when the concrete is hot. So the main concern with the concrete's strength and set time isn't really the air temperature but the concrete temperature.

When cement hydrates it sucks up water and grows crystals around the aggregate particles. When it's hot and that reaction is rapid, the crystals grow quickly but don't have time to grow strong. Early strength will be higher but 28-day strength suffers. If the concrete is about 18° hotter than normal (for example, 88° instead of 70°), the ultimate compressive strength will be about 10% lower.

Mini Delayed Set

Good for step-delay concrete pouring

Mini Delayed Set

Good for step-delay concrete pouring

Rescue-Pak

Contains six of our most effective admixtures

Rescue-Pak

Contains six of our most effective admixtures

Standard Delayed Set

Dry Powdered Admixture

Standard Delayed Set

Dry Powdered Admixture

POTENTIAL CONCRETE PROBLEMS IN HOT WEATHER

Slump loss

In hot weather, as the cement sets up, slump decreases rapidly and more mixing water is needed. This can also contribute to lower strengths (as much as another 10% lower), and in integrally colored concrete, can lead to variations in water content which can result in significant differences in concrete color between adjacent pours. A better solution is to modify your concrete mix, learn how in Concrete Admixtures for Hot Weather.

Evaporation

Another potential problem in hot weather is surface drying—although this one comes with a caveat. If the concrete is warm and the sun is shining and there is a hot dry wind across the concrete, yes, you are likely to get more drying and surface shrinkage. But let's go back to something every concrete contractor should know about—beer.

In 1987, G.E. Munro who was manager of technical services for Lafarge Cement, wrote an interesting article for the Lafarge newsletter. He started by posing a question: Does warm weather increase the probability of plastic shrinkage cracking? Most people would say, yes. But he advises us to think about a glass of beer on a hot summer day. If the beer is colder than the air, what happens? Water condenses on the outside of the glass. Concrete works the same way. If it is cooler than the air, Munro says by about 18°F or more, the chances are that water will be condensing on the surface rather than the surface drying out. The real problem with drying is when the air is cooler than the concrete. So if we can get cool concrete, we should be OK. This is NOT to say that hot weather can't cause increased cracking and plastic shrinkage cracking, because it can if the concrete temperature is high and the humidity is low.

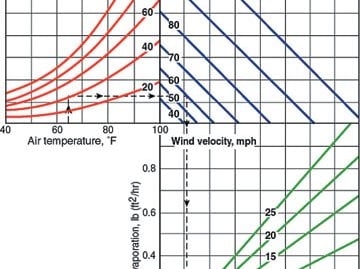

Start at air temperature, draw a vertical line up to relative humidity, then a horizontal line to the right to concrete temperature, then go vertically down to wind velocity, and horizontally to the left to determine the evaporation rate. If the evaporation rate is greater than 0.1, plastic shrinkage cracking is likely.

To determine if evaporation will be a problem, use the nomograph from ACI 305. Knowing air temperature, relative humidity, concrete temperature, and wind velocity, you arrive at a rate of evaporation. If the rate is greater than 0.1 pounds per square foot per hour, shrinkage cracking is possible.

Related: Curing Concrete in Hot Weather

Thermal differentials

Hot dry subgrades and formwork can also result in cracks by absorbing water from the mix. Another problem with heat and concrete is thermal differentials. All that means is that one part of the concrete mass is warmer than another part. If the differential is greater than about 20°F then you are likely to get cracks. This tends to be a particular problem in mass concrete (members thicker than about 18 inches).

Air content

Finally, maintaining air content can be a problem in warm concrete. Mixing is more likely to drive air out of the concrete making the level difficult to control.