- Concrete Stamps

- Get the Look - Stamping Pictures

- Buying Tips for Concrete Stamping Tools: Advice that will help you make smart choices

- Concrete Stamp Cost

- Types of Concrete Stamps: A comparison chart of popular stamps & patterns

- Stamping & Texturing Tools

- Concrete Stamp Mats

- Concrete Texturing Skins

- Medallion Stamps

- Texture Rollers

- Step Forms & Liners

- Installing Stamped Concrete

- How to Stamp Concrete

- Coloring Stamped Concrete

- Concrete Stamp Release Agent

- Sealers for Stamped Concrete

Stamped Concrete Release Agents - Powder vs. Liquid

How to use release agents to enhance the color and appearance of stamped concreteUsing release agents on a stamped concrete project is like casting character actors in a movie. They don’t play a starring role, but they are essential to good plot development.

Pigmented powdered or liquid release agents actually play two roles on a stamped concrete project: They act as bond breakers to prevent stamping mats and skins from sticking to the concrete and disturbing the imprint texture, and they impart subtle color to the concrete that enhances the integral or dry-shake color, resulting in an antiquing effect (see Concrete Color Hardener vs. Integral Color).

Powdered release agents are more traditionally used by stamping contractors because they offer more color selections. However, they have a few drawbacks. Because they are dusted onto the concrete surface, they create fine airborne dust particulates, so workers must wear dust masks to prevent inhalation. And on windy days, the airborne powder can stain nearby buildings, existing concrete flatwork, and landscaping, making it necessary to mask off adjacent areas with plastic or paper sheeting. To eliminate these issues, many contractors use clear liquid release agents and tint them with a powdered release (see Adding Color to a Tinted Release).

Applying concrete release powderMost manufacturers package powdered release agents in 30-pound pails. Typically, 30 pounds is enough to cover an area of about 1,000 square feet (or an application rate of 3 pounds per 100 square feet).

The best way to apply the release is with a dry tampico brush about 8 inches wide. Dip the brush into the pail of release and fluff it to load the bristles and coat them evenly. Then take the brush by the handle, holding it below belt level, and use your wrist to flick the release onto the surface in a light, uniform layer. Avoid applying too much release agent because it could interfere with the pattern imprint, especially lighter textures. Also, once the concrete is stamped and sealed, it can be very hard to remove the release powder if the color is too dark (see How to Remove Too Much Colored Release).

When applying a powdered release, try not to work more than a few rows ahead of the row being stamped. In windy conditions, any loose release laying on the surface could blow away. What’s more, the release agent may begin absorbing water from the concrete surface, causing it to dry out too quickly.

As you begin stamping the areas where release powder has been applied, watch for a lightening in the color of the release to help determine whether you’ve depressed the stamp completely. Regardless of the color you are using, the release will lighten when it has been fully compacted by the stamp.

Clear Liquid Release

Evaporates quickly and requires little cleanup.

Clear Liquid Release

Evaporates quickly and requires little cleanup.

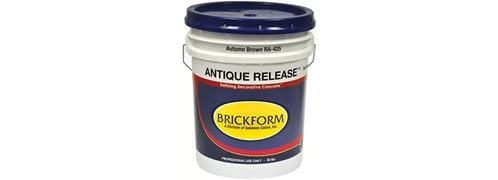

Antique Release Powder

Add depth and dimension, while preventing pull-up.

Antique Release Powder

Add depth and dimension, while preventing pull-up.

Premium Exterior Clear Sealer

High solids acrylic based sealer

Premium Exterior Clear Sealer

High solids acrylic based sealer

Bluestone Texturing Skin

6 skin set - only $1,173.20

Bluestone Texturing Skin

6 skin set - only $1,173.20

Five Point Star Medallion

Concrete stamp only - $292.00

Five Point Star Medallion

Concrete stamp only - $292.00

Brickform Stamping Tools

Precision stamping tools

Brickform Stamping Tools

Precision stamping tools

Applying liquid release agentUsing a pump-type sprayer, apply a uniform layer of liquid release onto the surface of the concrete right before you stamp. If you plan to use a tinted liquid release, add the tint a day or two beforehand, if possible, to allow the pigment particles to fully dissolve. Right before you pour the release into the pump sprayer for application, stir it well to mix in any release powder that may have settled to the bottom of the bucket so you don’t up with splotchy areas and nonuniform color. You can also strain the tinted release through cheesecloth or a strainer to eliminate any clumps of pigment. As you apply the release, be sure to shake the sprayer to keep the contents agitated so the pigment doesn’t have a chance to settle.

How to create color accentsWhen using release agents to create accent color on a stamped concrete project, a popular technique is to start with a light concrete base color (whether an integral color or a color hardener) and then apply a much darker release agent for contrast. Although about 70% to 80% of the release is washed away after the concrete hardens, the remaining release becomes depressed into the surface paste during stamping, which creates the subtle color accents. To obtain a random antiquing effect, apply a very small amount of powdered release to the surface of the concrete and then spray a liquid release over the top of it. The liquid dissolves the light layer of powder to leave subtle accents after the surface is stamped.

If you’re switching to a different release color, be sure to clean off the stamp mats between uses. For example, if you use a dark brown release on one job and then a few days later use the same stamps on another job with a light charcoal release, the dark brown could contaminate the charcoal color if you don’t thoroughly clean the mats first. Even if you use the same release color from day to day, it’s important to clean the mats if you see a layer of paste buildup that could affect the imprint quality.

Check out how contractors have combined stamped concrete color hardeners and release agents to create various dark and light color schemes (see Stamped Concrete Formulas).

For more information:Learn more about using powdered and liquid release agents in Bob Harris' Guide to Stamped Concrete.