Concrete Stain Videos

Watch videos on selecting the proper concrete stains, applying concrete stains, and the tools used to stain concrete.

Concrete Acid Stain Application Tips

Time: 05:32

See acid stain being applied to both an interior concrete floor and an exterior stamped concrete driveway. Get tips on the right equipment to use, applying the stain evenly, and cleaning and neutralizing after staining.

Concrete Acid Stains and Other Coloring Options

Time: 03:59

Acid stains can be used on interior and exterior concrete surfaces to produce natural, variegated coloring effects. See how they are used to enhance stamped concrete, and get tips on when to use acid stains versus other coloring options, such as concrete dyes and water-based stains.

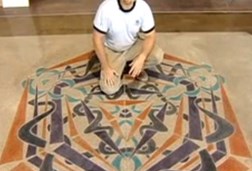

Concrete Dye Application Tips

Time: 03:09

Harris demonstrates the tools and application techniques for applying water-based dyes. For this project, he is using dye to enhance a decorative medallion in a previously stained floor.

Overhead Projector

Time: 01:55

Learn how-to use an overhead projector to trace intricate designs and high-end graphics onto your concrete surface. This works well when you are looking to combine a variety of decorative concrete methods, such as scoring concrete, polishing concrete, and coloring concrete, to create an intricate pattern. Use a forklift or ladder to raise the projector to the desired height so that the pattern on the floor is the appropriate size. Trace the pattern onto the floor using chalk. Then you can begin saw cutting and coloring following the outline of the pattern chalked onto the floor. Get five creative methods for creating graphics on concrete floors from Bob Harris.

Pump-Up Sprayer

Time: 05:37

Selecting the proper type of sprayer is critical to ensuring the best results when coloring or sealing concrete. Sprayers to be used with acid-based stains are usually identified with the label "acid" on the front. These are designed with acid resistant seals and sprayer tips that will not corrode when in contact with hydrochloric or muriatic acid. There are other sprayers available that should be used to spray acetone or alcohol-based products. Read the sprayer and product manufacturer's guidelines before applying stains or sealers. Also consider the sprayer tip you are using. The red tips allow less volume to be sprayed in a conical pattern and are typically used to spray acid stains. The grey tips allow more volume and are typically used to spray sealers.

HVLP Cup Gun

Time: 05:21

Learn how to use a HVLP (High Volume Low Pressure) cup gun for staining interior and exterior concrete floors. The reason for using the gun at a high volume of material but with a low pressure is to cut down on airborne chemicals. The pressurized spray gun is primarily used with water-based stains and dyes when doing detailed coloring work on concrete surfaces. Acid stains are never used in the HVLP cup gun because the gun is made of metal. The corrosiveness of the acid would destroy the metal. Even when using water-based stains and dyes, be sure to properly clean the cup gun after each use. You can also use a traditional artists air brush for extremely intricate detailed coloring.

Snapping Chalk Lines

Time: 01:12

When chalking out a decorative concrete job in preparation for saw cutting or coloring concrete, you need to be aware of the color and type of chalk you use. This is important because many of the red or blue chalks typically used contain a large amount of iron oxide that will stain the surface of the concrete and show through on the beautiful, decorative floor. It is best to use an orange chalk that is heavy in talc. This is often referred to as talcum powder and wipes cleanly away without staining.

Knee Pads & Respirators

Time: 02:03

It is important to follow the proper safety guidelines on the job. Be sure you always have the proper knee protection and respirators. Using knee pads will extend your concreting career as well as help prevent the need for knee surgery later in life. There are a number of knee pads and respirators to choose from. Perhaps the most important factor in selecting a respirator is making sure it is OSHA approved. Secondly, be sure that the respirator is the right one for the job you're doing. For example, if you are working on a job with only airborne dust particulate (fractured concrete in the air), you will need a different respirator than if you are applying a concrete dye that has chemical vapors. The cartridge on the respirator should indicate its proper use. If the cartridge says "chemical cartridge," it can be used when spraying products like acetones, xeylene, or acids.