- Concrete Step Forms

- How to Form Concrete Steps: See the process, and get tips on pouring steps using liners or foam forms

- Using Step Form Liners: Learn how to take the look of your stairways to a new level using textured step liners.

- Concrete Step Design

- Concrete Step Projects

- Restored Concrete Stairway

- Concrete Skateboard Steps

- Incredible Floating Steps

Using Concrete Step Form Liners

Learn how to take the look of your stairways to a new level using textured step linersWhen I think about how I used to texture stair risers prior to the inception of today’s commercially available step form liners, I appreciate just how useful these handy, reusable strips of textured polyurethane are for contractors trying to take their work to the next level.

During my days of concreting in theme parks, we poured, colored and stamped stair risers and treads almost every week. This usually entailed carefully removing the riser forms as early as possible without the concrete sagging so we could throw color hardener onto the fresh concrete stair faces, followed by working the hardener in with floats and trowels or making a paste out of the color and plastering it on. Shortly after, we would apply a layer of powdered release and then use polyurethane skins to emboss texture onto the vertical faces. This was usually followed by hand chiseling joints in the form of bricks or stones.

As you can imagine, this entire process was very time consuming and proved to be challenging in the warm months, especially if you had multiple risers and treads to texture. To save time, we would often fabricate our own crude step liners by cutting straight pieces from large texture skins and attaching them to the stair risers. Another improvised method we used was to brush solvent onto polystyrene foam strips. The solvent melts the foam away to create an interesting texture, depending on how heavily or lightly it is applied. We would usually affix the foam strips to the forms using two-sided tape.

My poor man’s versions of step liners have been replaced by highly sophisticated premanufactured liners offering numerous options for textures, designs (including bull noses and cantilevers), inside and outside corners and 90-degree intersections. Unfortunately, many contractors aren’t even aware that these liners are available, according to Harlan Baldridge, Pacific Northwest manager and technical field representative for Brickform, Rialto, Calif. “Most would be surprised at the number of contractors who haven't seen step liners, or if they have, don't use them to add value to their project,” he says. “I jokingly tell people I had both rotator cuffs rebuilt due to stripping and facing steps. Step liners save labor! I would say 25% or less of the contractors out there doing decorative work use them.

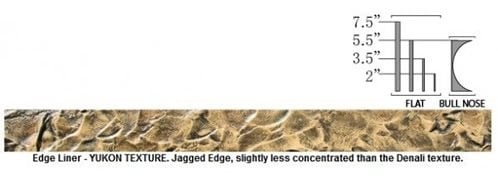

Applications and decorative optionsStep liners are not just limited to stair risers. Other applications include the edges of concrete wall caps, countertops, and benches. The liners are available in a wide array of designs, textures and sizes, making them extremely versatile. Tyler Irwin, national sales manager for Proline Concrete Tools, Oceanside, Calif., says that his company makes four different textures (Roman Slate, Denali, Yukon and Yosemite) and three different profiles (flat, hammered edge and bull nose). All are available in four different heights and 8-foot lengths, making for 41 possible variations. The company also makes custom step liners.

Brickform utilizes two grades of material to make a full 6- or 8-inch face liner as well as a dimensional lumber liner. All come in varying lengths and natural stone textures.

Butterfield Color, Aurora, Ill., offers liners in different heights so you can make the exact dimension needed for any job. “With Butterfield’s 2 ¼-, 4- and 6-inch cantilever liners and our riser liner sheets, you can make any size riser to fit your project. You are not stuck with a certain size to try and fit to your project because you can cut the liner sheet to fit under the cantilever liners,” says Dave Blasedale, Butterfield’s western region sales and training coordinator.

Step Form Liner – RomanSlate Pattern

from $59.00

Step Form Liner – RomanSlate Pattern

from $59.00

Edge Liners

Liners for limestone, Bullnose,and flat patterns.

Edge Liners

Liners for limestone, Bullnose,and flat patterns.

Brickform Step Liners

Edge Form Liners

Brickform Step Liners

Edge Form Liners

Denali Hammered Edge Liner

from $70.00

Denali Hammered Edge Liner

from $70.00

Butterfield Edge Form Liners

for Steps, Fire Pits, Walls, Wall Caps, Counters & more

Butterfield Edge Form Liners

for Steps, Fire Pits, Walls, Wall Caps, Counters & more

Concrete Stamps - River Rock Form Liner

from $108

Concrete Stamps - River Rock Form Liner

from $108

There are several coloring options when using step liners, depending on the final look you want to achieve. “I would say the most popular is using integral color on the step face and a contrasting color hardener on the flat surfaces to produce the most realistic results,” says Baldridge. “Most step liners produce enough texture, resulting in shadows that create depth in color. With that said, staining is always an option. With step liners, I think less is more! If you pour, vibrate, and strip late, the results are always good.”

In terms of cost, step liners are a viable option on most jobs. They provide multiple reuses and have a life expectancy similar to that of high-quality polyurethane stamps and skins. What’s more, they produce a high-end look that many customers are willing to pay more for. “Regular risers might get you $10 to $12 per linear foot. When using decorative step liners, you will be looking at charging $25 to $35 per linear foot, depending on the coloring process,” says Blasedale.

Tips for using step linersIf you are thinking about complementing your existing stamped concrete business with the addition of step liners, start off slow. Consider doing a few practice rounds and producing sample mock-ups. This way, when you are ready to take your new-found skills to the big leagues on an actual project, you will have the confidence to knock it out of the park with award-winning stairs.

Here are a few additional tips from the manufacturers we talked to for getting good results:

- For 45-degree corners, cut the liners using a chop saw or miter saw. Most step liners are also flexible enough to permit bending them into a very tight corner, leaving a rounded corner that is becoming very popular, says Irwin.

- If you have two identical liners, one can be rotated upside down from the opposing liner to avoid pattern duplication, says Baldridge.

- If using color hardener with liners, strip the concrete same day it’s poured. Then immediately broadcast the color hardener on the face of the riser so it can react with the moisture in the concrete, and let it set until the next day. Return the next day, wash off the excess hardener, and apply a sealer, says Blasedale.

- If you need to use more than one liner for a step edge or you need to cut a liner to fit the actual dimensions of the step, you can eliminate seam marks by rubbing the seam out with your finger and blending it in while the concrete is still wet. If striping the step forms later or if the concrete has thoroughly dried, carefully chisel the seam out, dampen it, and rub it lightly to work up some paste. Then blend the paste in. You can also use a fast-dry caulk to fill the seams in the liners prior to concrete placement, says Blasedale.

For more information

Brickform (www.brickform.com)

Butterfield Color (www.butterfieldcolor.com)

See how concrete step form liners are used

Video: Form Liners for Concrete Steps

RELATED:

Concrete Stamps

Form Liners for Walls