- GFRC Home

- Benefits of GFRC

- Design Ideas for GFRC

- Applications for GFRC

- Countertops

- Fireplace Surrounds

- Architectural Accents

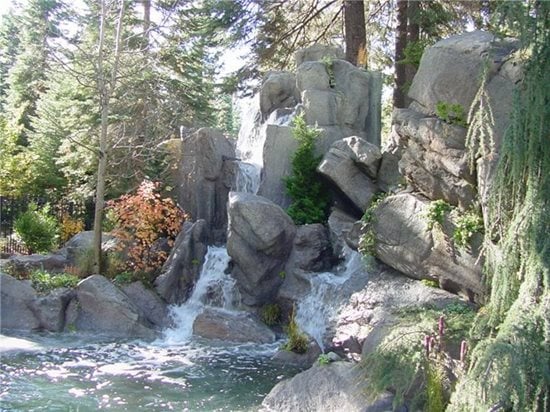

- Faux Rock

- Mixes and Materials for Making GFRC

- Glass Fibers for GFRC

- Mixes and Materials for GFRC

Benefits of GFRC

There are lots of good reasons to use GFRC for thin sections of concrete:

Large artificial rocks made with GFRC are lighter allowing rock features where real rock would be impossible. NEG America

- Lighter weight: With GFRC, concrete can be cast in thinner sections and is therefore as much as 75% lighter than similar pieces cast with traditional concrete. According to Jeff Girard's blog post titled, "The Benefits of Using a GFRC Mix for Countertops", a concrete countertop can be 1-inch thick with GFRC rather than 2 inches thick when using conventional steel reinforcement . An artificial rock made with GFRC will weigh a small fraction of what a real rock of similar proportions would weigh, allowing for lighter foundations and reduced shipping cost.

- High strength: GFRC can have flexural strength as high as 4000 psi and it has a very high strength-to-weight ratio.

- Reinforcement: Since GFRC is reinforced internally, there is no need for other kinds of reinforcement, which can be difficult to place into complex shapes.

- Consolidation: For sprayed GFRC, no vibration is needed. For poured, GFRC, vibration or rollers are easy to use to achieve consolidation.

- Equipment: Expensive equipment is not needed for poured or vibrated GFRC with a face coat; for sprayed GFRC, equipment generally costs about $10,000.

- Toughness: GFRC doesn't crack easily-it can be cut without chipping.

- Surface finish: Because it is sprayed on, the surface has no bugholes or voids.

- Adaptability: Sprayed or poured into a mold, GFRC can adapt to nearly any complex shape, from rocks to fine ornamental details.

- Durability: According to ACI 544.1R-96, State of the Art Report on Fiber Reinforced Concrete, "The strength of fully-aged GFRC composites will decrease to about 40 percent of the initial strength prior to aging." Michael Driver, division manager with Nippon Electric Glass, a major manufacturer of AR glass fibers, disagrees. "There's never a durability issue. Water can't get in-there are no cracks-and that's a durable material. GFRC will outlast precast concrete, cast stone, even some natural stone." Durability has been increased through the use of low alkaline cements and pozzolans.

- Sustainable: Because it uses less cement than equivalent concrete and also often uses significant quantities of recycled materials (as a pozzolan), GFRC qualifies as sustainable.

- Cost: GFRC as a material, however, is much more expensive than conventional concrete on a pound-for-pound basis. But since the cross sections can be so much thinner, that cost is overcome in most decorative elements. "When you keep the thickness to about ¾ inch, the material cost is typically less than $2.00/square foot," said Driver. "Because of the high modulus of elasticity of the glass, it replaces all of the steel, but once you get into 4-inch slabs, the GFRC becomes cost prohibitive."

- "GFRC hasn't caught on like it could because of the mix design," said Driver. "When you have so much cement, your chemistry changes and you have a lot of variables to control. Many regular concrete guys have problems and end up disgruntled. It takes some time to become proficient with GFRC. There's a lot to know, a lot of variables. Training is key."

GFRC ResourcesThere's a ton of information available on GFRC and also some training and free technical advice:

- Nippon Electric Glass America will provide training and technical support. NEG America's Michael Driver recommends that manufacturers interested in producing GFRC products need to participate in hands-on training prior to any attempts at making this type of material. "Most GFRC mixes contain more cement than aggregate and typically include acrylic latex polymers for curing," he said. "Variables such as cement chemistry, aggregate gradation and shape, mix temperature, water chemistry, water reducing admixture type, AR glass fiber aspect ratio, fiber orientation, fiber content, and curing conditions are just a few that need to be considered. Without knowledge of these variables, the novice GFRC manufacturer can become discouraged after just a few failed attempts."

- The Precast/Prestressed Concrete Institute has a wealth of information on GFRC manufacturing in PCI MNL-128 Recommended Practice for Glass Fiber Reinforced Concrete and PCI MNL-130 Quality Control Manual for GFRC.

- ACI's state of the art report on fiber reinforced concrete, ACI 544.1R-96, is slightly old now (1996) but has a long chapter on GFRC.

- Stromberg Architectural Products, which manufactures architectural accents, has an extensive handbook on GFRC that is available for free download.

- The Glassfiber Reinforced Concrete Association, the GRCA, is a British-based but international association dedicated to advancing knowledge on GFRC. They have an excellent brochure on GFRC applications, called "GRC in Action," that is available for free download.

Find Manufacturers: GFRC Mixes

Find Local Suppliers: Decorative Concrete Stores

Featured Products

Clean Cast GFRC Mix

Available in white or gray, in 50lb bags

Clean Cast GFRC Mix

Available in white or gray, in 50lb bags

Hopper Gun

Large capacity hopper holds 2.5 gallons

Hopper Gun

Large capacity hopper holds 2.5 gallons

Hand Held Power Mixer

Professional grade, single paddle mixer.

Hand Held Power Mixer

Professional grade, single paddle mixer.