- Colored Concrete Home

- Concrete Color Charts

- Ways to Color Concrete

- Concrete stains

- Integral Color

- Dry-Shake Color Hardener

- Concrete Dyes

- Concrete Paint

- Comparison Chart: Concrete Coloring Products

- Design Ideas for Colored Concrete

- Which Color Scheme is Right for Your Home?

- Creating color and texture with Stamped Concrete

- Adding Interest with Exposed Aggregate

- Creating Excitement with Color: Endless Possibilities with Polymer Stain

- Related Information:

- Problems with colored concrete: Common problems, why they occur, and how to avoid or fix them

- Guide to Buying Concrete Stains and Dyes

- Lea este artículo en español

How to Fix Concrete Color Issues

Expert tips on solving concrete coloring problemsFind concrete coloring contractors near me

Select Your Problem

How to Fix Stamped Concrete Color

Why is My Colored Concrete Turning White?

Poor Drainage is Causing Sidewalk Discoloration

Never Apply Integral Color to the Concrete Surface

Excess Antiquing Color Causes Problems

How to Fix Blotchy Colored Concrete

HOW TO FIX STAMPED CONCRETE COLOR

Question:

How can I change the color of a stamped slab after it has been poured? The customer was not happy with gray and now wants a reddish-brown color.

Answer:

You can change the color of stamped work once it has been placed by applying different types of stains, tints, or dyes. To find out how and get the complete answer, see Changing the Color of a Stamped Driveway.

DYES VS. STAINS: WHAT ARE THE DIFFERENCES?

Question:

I hear a lot about using dyes on concrete. What are they, and how do they differ from chemical stains?

Answer:

Dyes are the latest buzz in the decorative concrete community. Their ease of use, extensive palette, and vibrancy of color (which can be more intense than chemical stains) are creating a wave of popularity that is gaining momentum. To learn about the differences, see Dyes vs. Stains.

WHY IS MY COLORED CONCRETE TURNING WHITE?

Question:

Last week, we poured a band of integrally colored black concrete. It looked great for three days, but then it rained a little the night of the third day, and by the next morning all the black color had disappeared, hidden by a grayish-white surface discoloration. What happened, and how do I fix this?

Answer:

This is one of the most common, but least understood phenomenons with concrete. Efflorescence is a chalky white salt residue that can occur with any product containing cement. As moisture migrates up to the surface of the concrete, it carries along with it calcium salts from within the concrete. When the salts reach the surface, they react with CO2 in the air and form insoluble calcium carbonate. This white, dusty, scaly salt can be minimal or dramatic, depending on the amount of free calcium salt present in the concrete. Exposure to rain, standing water, and sprinklers only makes the situation, as water triggers the reaction and creates more efflorescence. To get the complete answer, see Efflorescence on Black Concrete.

POOR DRAINAGE IS CAUSING SIDEWALK DISCOLORATION

Question:

I am coordinating property improvements for a homeowner in the Los Angeles area. A concrete walkway poured by a licensed contractor less than a year ago is showing efflorescence and strange color variances. The sidewalk is tinted a Santa Fe color and is 4 inches thick, with a brushed finish. I was told by the contractor that it would take awhile to cure and to expect it to do all sorts of "weird stuff" while it was curing. But now the walkway is mottled and looks like a pinto pony. The contractor said the uneven color was because overhead sprinklers on a hill above the walkway were keeping it too wet. Also, the wetting was uneven across the length of the project. I revamped the sprinklers so they have almost no contact with the walkway, and waited for it to dry out. Some of the pinto effect did fade, but the concrete still has dark areas. The contractor said he is thinking about doing a light vinegar wash to help with the problem.

Located at the foot of a hillside, this sidewalk is showing mottling and efflorescence due to poor drainage and over-irrigation.

Located at the foot of a hillside, this sidewalk is showing mottling and efflorescence due to poor drainage and over-irrigation.

A close-up of the pitting, showing the brownish ooze seeping up from the holes.

A close-up of the pitting, showing the brownish ooze seeping up from the holes.

Recently, I noticed an even bigger problem: pitting! An amber-colored goo is coming up from below the surface through round areas about the size of a quarter, where the concrete has broken off. On closer inspection, you can see small rocks in the middle of some of these pits, while other pits have nothing in them but are very unsightly. The area also has a few star-shaped popouts. This pitting problem is sporadic along the entire 125-foot length of the sidewalk, but it is more pronounced in some areas. The areas that got less or no overspray from the sprinklers have less pitting. Are the discoloration and pitting problems caused by the sprinklers, or is there something more to it? Please tell me what can be done with this mess.

Answer:

You have multiple issues going on, so I will address each individually. First, the cause of the discoloration is pretty straightforward. As your contractor said, it is due to moisture. Because the sidewalk sits at the bottom of a pretty steep hill that is irrigated year-round, moisture is migrating downhill and soaking into the concrete. Even if you stopped watering altogether, you would still have ambient moisture in the soil moving down and affecting the concrete. Magnifying the problem is the fact that the concrete sits at the bottom of the hill, where the water concentrates. Making matters even worse is that you have irrigation and plants on the house side of the concrete as well, so it gets wet from both sides. How much sun does the concrete get? It looks pretty shaded, which does not help the situation. You stated that you changed the irrigation system, with some improvement. But the only way to get rid of the discoloration is to stop the flow of water. Since it is unrealistic to stop irrigating, you need to install some type of moisture block (such as a plastic barrier with a French drain) to keep the water from touching the concrete. A less-expensive option is to apply a special waterproofing sealer to the concrete. That will help, but it won't completely stop the water migration.

The efflorescence problem is also caused by moisture. Stop the water, and you stop the white haze of efflorescence from forming. You could remove the efflorescence by using the mild acid cleaner, or vinegar wash, as your contractor recommended, but unless the water is stopped, the discoloration and white haze will return. See this guide to efflorescence and the measures you can take to prevent it.

Finally, the pitting appears to be caused by alkali-silica reaction, or ASR. In a nutshell, ASR is a complex chemical reaction between water and certain silica aggregates in concrete that causes expansion forces exceeding that of the concrete matrix. ASR or varying forms of it can show up as random cracking or popping and pitting of the concrete surface. This link to information from the Portland Cement Association will tell you more about ASR and its causes.

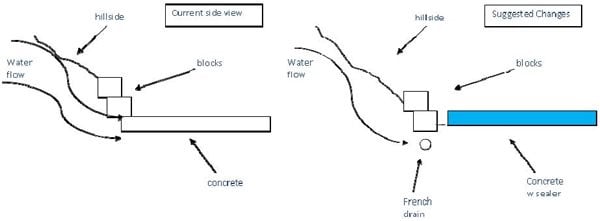

Here's the bottom line: The location of the sidewalk, the water migration, and the makeup of the concrete are all converging in a perfect storm to cause these problems. My recommendation is to use a lithium-based penetrating concrete sealer, along with some landscape modifications. The sealer will help fill the pores of the concrete to slow or stop the flow of water from below the sidewalk to the surface. This will help to prevent the white efflorescence and even out the color. First, a good cleaning will be needed to prepare the concrete to take the sealer. Refer to the recommendations provided by the sealer manufacturer. I would also cut back the hillside and position the retaining wall blocks on the soil, rather than on the concrete (see drawing). Re-grade the ground so that the blocks sit lower than the concrete, and that area becomes the low point. Then install a French drain in the new low spot to help move water away.

NEVER APPLY INTEGRAL COLOR TO THE CONCRETE SURFACE

Question:

I just purchased a home with a concrete patio that was poured 5 years ago. I was told by the previous homeowner that the person who poured the concrete added the color by hand, sprinkling it on top after the pour. The color was not mixed in with the concrete. He used 1-pound color packs that are supposed to add color to a 60-pound bag of concrete mix. The color is uniform, but every time we step on the patio, the color comes off on our shoes and appears to be flaking away. The concrete surface also appears to be somewhat soft. When moving a table the other day, I noticed that when I dragged it across the patio, it etched into the concrete. I have tried sealing the surface, but the sealant doesn't stick in all areas. What are my options? Is there anything I can do to prevent the flaking and rubbing off of the color, or do I have to remove the entire patio?

Answer:

The color packs that the contractor used are designed to integrally color concrete rather than be cast onto the surface. Integral color should never be used as a surface-applied colorant. It has no binder, so it must be mixed in with the concrete to "lock in" and bond. If it's applied to the surface, there is no way to get a strong bond between the color and the concrete. That's why the color on your patio is flaking off and the surface is weak. The proper product for surface application is a color hardener, which contains color, sand and cement and is broadcast on the surface and worked in while the concrete is still wet. Color hardener will actually produce a stronger surface because of the additional cement and sand contained in the product.

In this case, there is no way to strengthen the soft top layer. And applying sealer to the surface is like sealing over dust or dirt. The sealer is clinging to a weak layer, which is why it's not adhering. You don't need to remove the entire patio, however. The best approach is to use a power washer or grinder to remove the soft top layer until you get down to solid concrete. After removing the top layer, you can keep the concrete gray or use a microtpping overlay or stain to add back some color if desired.

Related: Problems with Integrally Colored Concrete

Find Concrete Stains, Concrete Dyes, and Integral Colors & Hardeners

EFFLORESCENCE DISCOLORS MEMORIAL WALL

Question:

We built a veterans' memorial last year and used a color additive in the concrete. Since our dedication ceremony, the color appears to have leached out, leaving a whitish limestone-like appearance. I have attached pictures to give you an idea of what we are up against.

A classic example of efflorescence, and the whitish discoloration it can cause.

Answer:

This is a classic case of efflorescence - calcium-based scale leaching to the surface of the concrete. This is a natural process and occurs in all concrete.

In regard to this particular case, the best way to proceed is to clean away the efflorescence and seal the concrete. Cleaning can be accomplished with a very dilute acid (40 parts water to 1 part muriatic acid) or even better, a non-acidic efflorescence remover. (Check out Prosoco for more information on these types of cleaners.)

No matter the cleaning chemicals used, apply the solution directly to the affected area and scrub lightly to loosen the white salt residue. Rinse the area with clean water. Let the surface dry thoroughly, then seal. I recommend using an impregnating waterproofing sealer to stop the movement of salts to the surface. It can be any type of silane, siloxane or silicanate, available at most concrete material or stone distribution centers. If you want to darken the concrete color or give it a glossy appearance, apply a low-solids acrylic sealer as a final coat. The most important step with this project is to seal the concrete once the surface is clean and dry. If no sealer is used, the efflorescence will reoccur and in six months the wall will look white again.

In closing, thanks to you and all your members for their service to country and community!

Find Concrete Cleaner & Sealers

EXCESS ANTIQUING COLOR CAUSES PROBLEMS

Question:

I have a pool deck in which the sealer seems to be flaking off and coming up in some areas. This is not an issue that we have dealt with before, so I am a little concerned. Can you let us know what is occurring and how we can remedy this issue?

Answer:

This is actually one of the most common issues we face with coloring stamped concrete. It is in fact not a sealer issue, but rather the antiquing color that is causing the sealer to fail. The sealer failure can occur within weeks of application, but more often shows up 6 to 12 months down the road.

Imprinted concrete looks pretty bland and unrealistic without highlights or antiquing, which give the pattern definition and color variation. These highlights make the concrete look like stone, tile or whatever natural material the installer is trying to mimic. The highlights can be accomplished in a multitude of ways, with release powder being the most common. Other popular methods include stains, tints, dyes and colored sealers. Virtually any means of getting some contrasting color to stick in the depressions and textured areas of the surface will work. The problem occurs when too much secondary color is present. The depth and type of texture on the imprinting tool will determine the amount of secondary color to use. More aggressive textures with deep grout lines, lots of deep veins, and rough slate or stone surfaces will accommodate more secondary or antiquing color. The opposite holds true for light textures with smoother surfaces and non-aggressive patterns. A good rule to work by is that secondary color should make up 5% to 30% of the final color. In your case, however, the secondary color makes up almost 100% of the surface color.

The real curve ball is that stamped work with such high ratios of secondary color can look amazing and beautiful. Once sealed, the work looks great, the applicator gets paid and everyone is happy. The problem is that you have ticking time bomb, and it is just a matter of time before it explodes. Have you ever considered what secondary color is made of and how it works? No matter whether you use release powder, stains, washes or tints, you are filling the surface pores of the concrete with solid material. Those solids are filling the voids that the sealer needs to fill in order to "bite" or adhere to the concrete. The more secondary color present, the bigger the problem. The sealer will encapsulate the solid color in an attempt to do its job, but if there are no pores to fill, adhesion is compromised, which leads to failure when external forces exceed the ability for the sealer to hold. This is usually why we see these types of failures in the spring, after a winter assault of freeze-thaw cycles, deicing salts and snow shovels. As a result, the sealer lifts up in small circular areas and takes the secondary color with it, since the color is all it had to hold onto. You are then left with a stamped slab that has round, discolored spots. The "discoloration" is actually the base color that should have been visible in the first place, but was covered with too much secondary color.

The repair is fairly simple in theory, but more difficult in practice. The sealer has to be chemically stripped, but the process will usually remove most of the secondary color as well. Once the stripping is complete, you can remove any residual secondary color, give the surface a good cleaning, and then allow it to dry before resealing. The hard part is selling the client on the new "correct" color combination of their patio. What was mostly dark brown with hints of tan is now mostly tan with hints of dark brown.

CURING COLORED CONCRETE

Question:

This integrally colored floor was cured with a non-breathable curing paper. What are the white marks on the surface, and how do we remove them?

Answer:

A non-breathable curing material will create a vacuum that sucks moisture from the concrete up to the surface. The moisture then has nowhere to go because it is trapped beneath the non-breathable covering. Anything carried to the surface along with all that moisture (such as natural salts in the concrete) will be left on the surface as the moisture evaporates once the covering is removed.

The white haze on the concrete surface seen in the picture is dried salt residue, or efflorescence, that was left behind when the cover was removed. Non-breathable curing membranes tend to create more efflorescence because of the dramatic vacuum they create when placed on wet concrete. A breathable covering is always preferred, especially on colored concrete.

In this case, using lots of water to remove the surface salts while they were still wet would have minimized the white haze. Now, however, multiple passes of a rotary scrubber with a scrubbing pad are needed to remove the deposits.

HOW TO FIX BLOTHCY COLORED CONCRETE

Question:

What would cause half of this integrally colored concrete pool patio to look so washed out? The ready-mix supplier claims to have put color in the mix, but the finisher claims to not have seen any color when placing the load. Is there any way to determine if color is actually in the concrete?

Answer:

Because so many factors can affect the appearance of concrete-when placing the mix as well as after the concrete is in place-an internal sample is the only sure way to determine the presence of color throughout the concrete slab. In this case, a core sample was required because the slab is above grade and surrounded by walls on all sides, although taking cores is usually the last resort because of the cost and the hole it leaves behind in the concrete. (The same information can be obtained nondestructively by looking at a scrap piece or retained sample of the concrete.)

The core sample from this pour shows that color is indeed present throughout the slab. This means that something affecting the surface is causing the off-color. Further investigation found that the pale areas of the pour where placed at a different time. These areas also have a blotchy white surface effect, known as efflorescence-a calcium carbonate residue that leaches out of concrete over time. (I'll cover the causes of efflorescence in more detail in another Q&A). When too much efflorescence exists, it can totally hide the true color of the concrete.

Mild acidic cleaners or specialty cleaners for efflorescence are the best way to remove the white, chalky substance. Following up with the application of a sealer is always a good idea, since efflorescence can return if moisture gets into the slab, starting the chemical reaction all over again.

CONCRETE COLORING TECHNIQUES

Question:

What is the difference between base color and secondary color in stamped or imprinted concrete?

Answer:

The base color refers to the primary color of the concrete. Most stamped concrete is colored with pigments that are either added to the mix (integral color) or surface applied (shake-on color hardener). While both are good methods of coloring concrete, color hardener provides greater color selection and enhances the strength and durability of the concrete surface.

For most decorative stamping work, lighter base colors

are accented by darker secondary colors. In this case,

he results mimic naturally weathered stone.

Secondary colors are used over the base color as contrasting accents or highlights. The contrast is what makes stamped concrete come alive, and provides the perception of stone, tile, wood, or rock. There are many different products and methods for imparting secondary color, depending on the final look desired and the applicator's preference. These include, but are not limited to, pigmented release powder, tinted liquid release, stains, tints, dyes, and tinted sealers. The most common, and arguably most practical method for adding secondary color to stamped concrete, is to use a pigmented release powder during the stamping process.

There is no limit to the number of base or secondary colors that can be used. In fact, blending multiple colors, in both the base and secondary applications, can add to the overall realism of the results. An important factor to keep in mind: The secondary color should make up no more than 40% of the final color you see. Anything more then that can impair the adhesion of the sealer to the concrete surface.

Find Concrete Stains, Concrete Dyes, or Integral Color & Hardeners

HOW TO REMOVE TOO MUCH COLORED RELEASE AGENT

Question:

I installed a stamped concrete slab for some homeowners, and they decided they wanted more of the colored release agent removed from the slab after I had already sealed it. They thought it looked too dark. How do I remove the sealer and wash off the release to reduce the intensity of the secondary color?

Answer:

When concrete is stamped using colored antiquing release, the stamps actually push some of the colored powder into surface of the concrete. This process causes the secondary color to be permanently encapsulated in the surface paste of the concrete. So, without writing a Master's thesis and getting into a lot of chemistry, I will keep it simple and tell you that it will be very hard to remove the colored release powder if the slab was stamped properly. The sealer, however, can be removed with a chemical stripper (see Advice on Using Chemical Strippers and The Concrete Network article Best Method for Stripping Sealers).

During that process, you may be able to remove some of the release color. Try attacking the concrete with a stiff-bristle brush, and scrub until you remove some color. This can take a long time, and produce a lot of sweat. If you need to remove more color, try using a very dilute acid (40 parts water to 1 part muriatic acid). Spray down the dilute acid, covering small sections of the slab at a time, then scrub it in with a brush and rinse with soapy water. The acid will actually take up some of the concrete paste, along with some of the color. Test this in an inconspicuous area first to be sure you are getting the results you and the homeowners desire.

Find Concrete Stains, Concrete Dyes, & Concrete Cleaner

MOISTURE 'FORCES' DYE OUT OF CONCRETE

Question:

We applied concrete dyes to the floors in several rooms of this house, but the dyes failed and we are seeing a white powdery residue. We also have areas where blue painter's tape is pulling off the dye and sealer. Based on the photos, can you help us figure out what went wrong and what we can do to fix the problem?

Efflorescence caused by moisture-vapor transmission causes sealer and dye to "pop" off.

Efflorescence caused by moisture-vapor transmission causes sealer and dye to "pop" off.

Glue from painter's tape bonds with the sealer

Glue from painter's tape bonds with the sealer and pulls off the sealer and dye.

Answer:

You have two issues going on with these dyed floors. The first is moisture-vapor transmission, or MVT. This is the cause of the white crystal growth and white powder residue you are seeing. On indoor surfaces, it usually occurs along the outside walls, or near joints and cracks where moisture can easily penetrate and hold. Did the floors go through a wet winter or spring? Are the areas where the white residue is occurring near walls or exterior landscaping that is wet or holds water, such as lots of dirt built up alongside the outside wall? Water in concrete, whether in liquid or vapor form, picks up excess salt and carries it to the surface. This is known as efflorescence. (For more information, see Efflorescence on Black Concrete.) The pressure from the moisture vapor and salts either doesn't let the dye penetrate to start with or actually forces it out of the concrete over time. It looks like the latter is occurring with your slab.

The second issue is "tape pull," caused by the plasticizers in the glue on the painter's tape penetrating into the sealer and creating a very strong chemical weld (see Tape Marks on Concrete Floors). This can occur very quickly, and even with weak painter's tape can form a very strong bond. Time, heat and pressure make this worse, as well as the type of tape that is used. The bond of the dye to the concrete and the sealer to the dye and concrete also play a part. Usually we find that when blue painter's tape pulls up the dye and sealer, as in your case, there were underlying issues with the original dye penetration and adhesion. This also could be related to the MVT issue discussed above. It is best to never put tape on sealed concrete.

Now, here are some ways to fix your problems. If the dye failure is isolated to a few small areas, you may be able to clean the floor with a mild acid, neutralize the area, let it dry, and then touch it up with tints, dyes or a tinted sealer. The problem with this approach is that it does not address the root of the problem, which is MVT. If the source of the moisture is something you can control or fix, such as a broken pipe or sprinkler line or regrading of the exterior landscaping, then taking care of those issues should stop the problem. If you can't stop the moisture, the problem will probably occur again, which means the floor will need to be treated and waterproofed. This usually requires stripping back down to bare concrete, applying a waterproofing sealer or membrane, and then coming back with a topping that can be dyed or sealed. The repair route take you take will have a lot to do with how widespread the issue is, where the moisture is coming from and how much time and money you want to spend to fix the problem.

To cover the marks from tape pull, try faux painting the spots with tints or dyes in colors that will blend with the surrounding areas.